A kind of bed material carrier particle for fluidized bed sewage treatment system and preparation method thereof

A technology of sewage treatment system and carrier particles, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of no literature reports, etc., and achieve low manufacturing cost, stable performance, The effect of low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

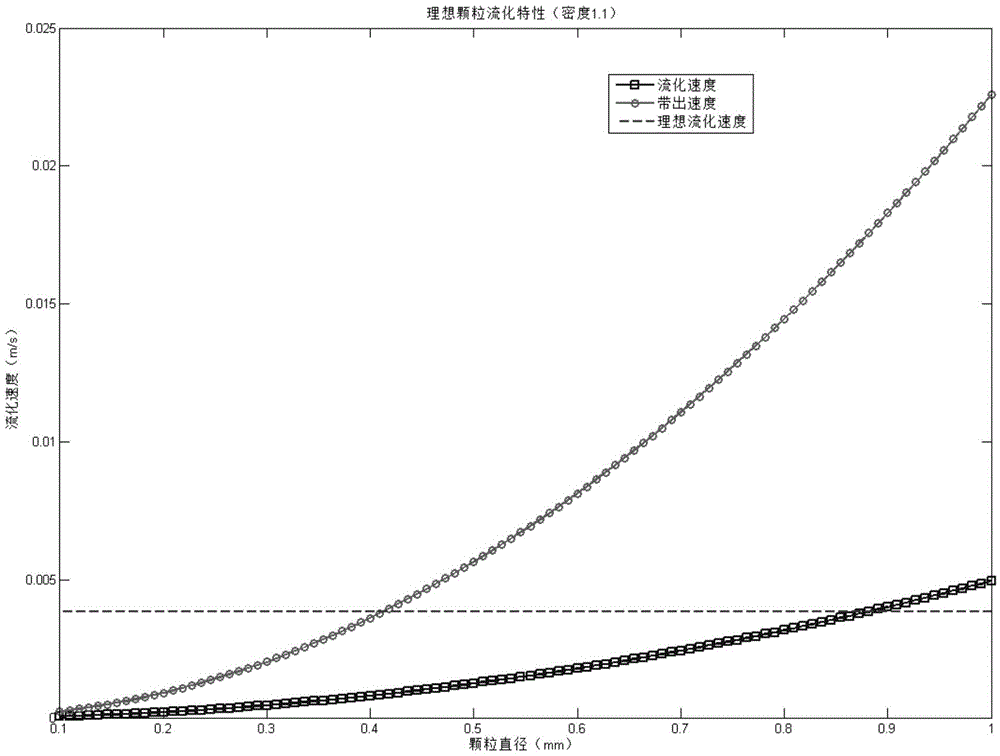

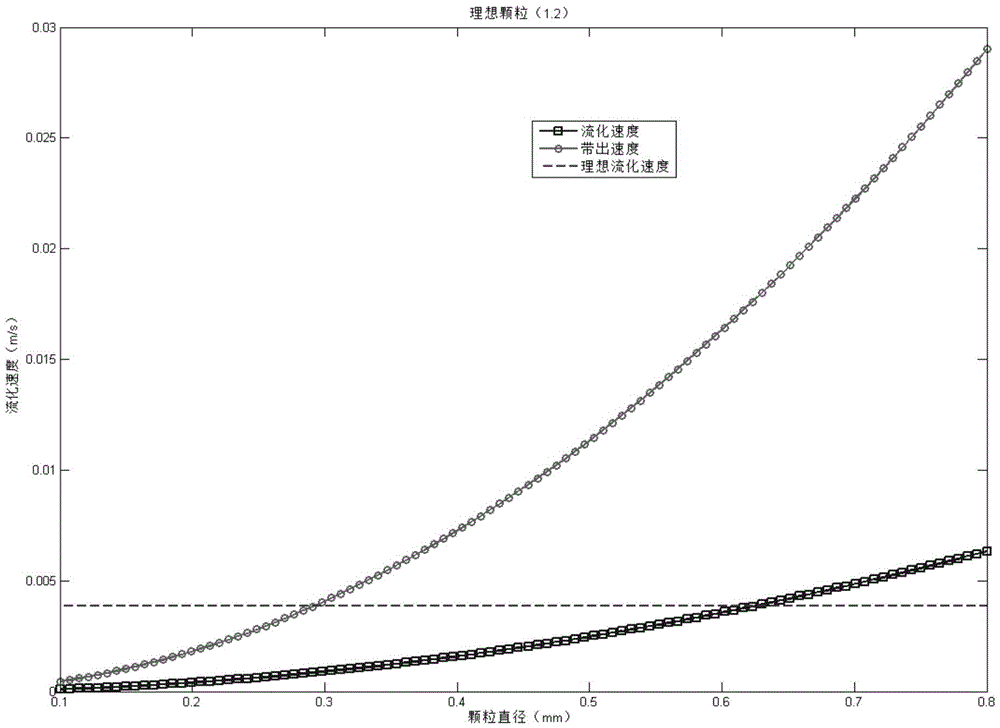

[0030] A bed material carrier particle for a fluidized bed sewage treatment system, which is prepared from quartz sand powder and polyethylene in a ratio of 0.15:0.85, and the preparation method includes the following steps: mixing inert filler and plastic, and then heating until the plastic melts temperature, after the mixture is mixed evenly, it is prepared into cylindrical or spherical particles through wire drawing and granulation process (such as image 3 shown), the obtained carrier particle density is 1.20X10 3 kg / m 3 , The particle equivalent diameter is 0.6mm. Such as figure 2 As shown, the fluidization velocity of the carrier particles in the sewage can be controlled at about 5mm / s, and the particle take-out velocity is about 18mm / s. Under the condition of ensuring an appropriate reflux ratio, it is beneficial to reduce the overall operating energy consumption of the system. At the same time, the take-out speed is about 4 times of the normal fluidization speed, ...

Embodiment 2

[0036] Referring to Example 1, the difference is that the carrier particles are prepared by mixing limestone powder and recycled mixed plastics at a ratio of 0.25:0.75, and the prepared carrier particles have a density of 1.30×10 3 kg / m 3, The particle equivalent diameter is 0.3mm. The obtained carrier particles are soaked in scrap iron powder water with a mass fraction of 0.1% for 24 hours before being put into a sewage fluidized bed.

Embodiment 3

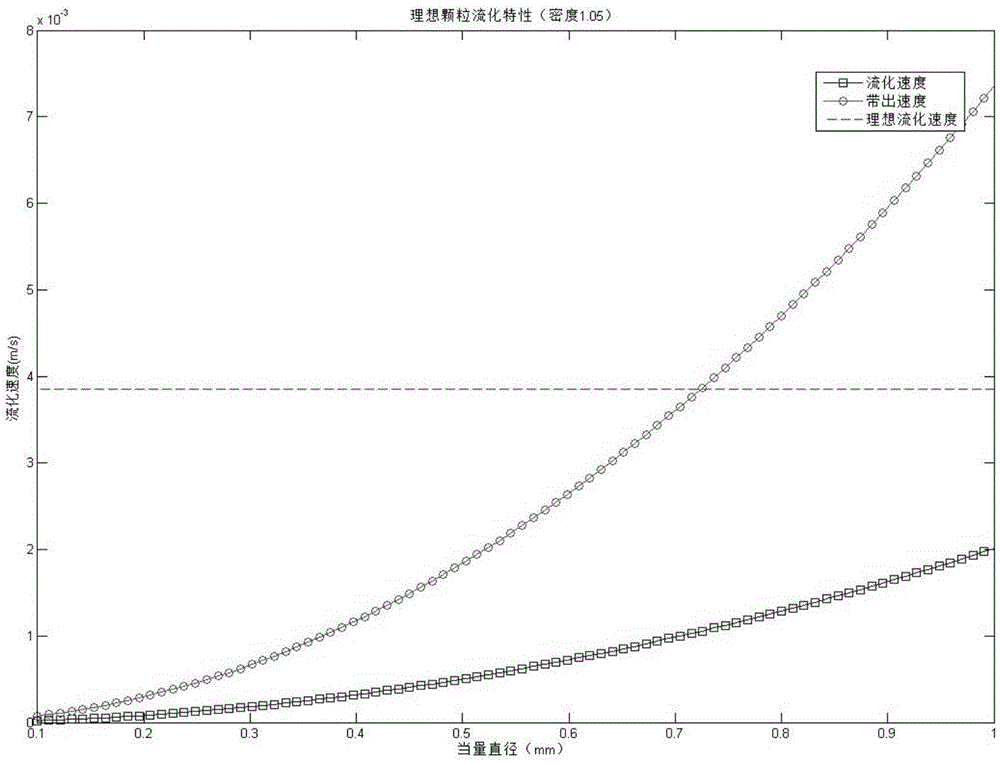

[0038] Referring to Example 1, the difference is that the carrier particles are prepared by mixing limestone powder and recycled mixed plastics at a ratio of 0.05:0.95, and the prepared carrier particles have a density of 1.05×10 3 kg / m 3 , The particle equivalent diameter is 1.0mm. The obtained carrier particles are soaked in scrap iron powder water with a mass fraction of 0.5% for 30 hours before being put into a sewage fluidized bed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com