Method for preparing hydroxypropyl methylcellulose acetate succinate

A technology of hydroxypropyl methylcellulose and hypromellose acetate, which is applied in the field of preparation of hypromellose acetate succinate, can solve the problems of many by-products, slow acylation reaction rate, and poor water resistance, and achieve The effect of speeding up the reaction rate, speeding up the reaction speed, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

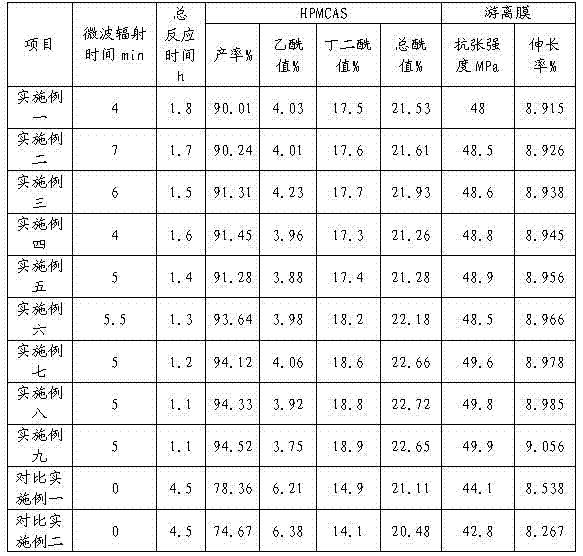

[0030] Weigh 100g of hydroxypropyl methylcellulose, 10g of anhydrous sodium acetate and 20g of glacial acetic acid, stir and mix evenly, then add 25g of succinic anhydride and 30g of acetic anhydride; microwave the mixture for 4min under 400kw power, and naturally Cool to 50°C to obtain the reaction product; pour the reaction product into water, and after the reaction product is completely precipitated, wash and suction filter until the precipitated liquid is neutral; dry the filter cake obtained by suction filtration in a vacuum oven at 80°C, Obtain hypromellose acetate succinate, and the yield is shown in Table 1.

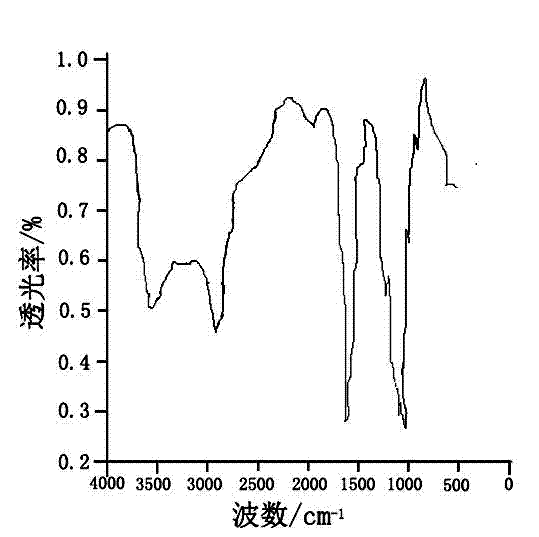

[0031] The product was analyzed by infrared, the results are shown in figure 1 . The absorption range of carboxylic acid (-COOH-) and carboxylic acid (-COO-) groups is 1720-1770cm -1 , figure 1 shows that at a wavenumber of 1740 cm -1 Strong sharp absorption peaks can be found at 1069, 1139 cm -1 The absorption peak at is confirmed to be the C-O-C stretching...

Embodiment 2

[0035] Take 100g of hydroxypropyl methylcellulose, 50g of anhydrous sodium acetate and 60g of glacial acetic acid, and mix them ultrasonically for 10 minutes, then add 75g of succinic anhydride and 50g of acetic anhydride; microwave the mixture at 750kw for 7 minutes, and cool it naturally The reaction product was obtained at 70°C; the reaction product was poured into water, and after the reaction product was completely precipitated, it was washed and suction filtered until the precipitated liquid was neutral; the filter cake obtained by suction filtration was dried in a vacuum oven at 80°C to obtain Hypromellose Acetate Succinate.

[0036]

Embodiment 3

[0038] Take 100g of hydroxypropyl methylcellulose, 40g of anhydrous sodium acetate and 30g of glacial acetic acid, and mix them ultrasonically for 8 minutes, then add 30g of succinic anhydride and 38g of acetic anhydride, and then stir for 5-8 minutes; microwave the mixture at a power of 500kw After 6 minutes of radiation, naturally cool to 50-70°C to obtain the reaction product; pour the reaction product into water, and after the reaction product is completely precipitated, wash and suction filter until the precipitated liquid is neutral; filter the filter cake obtained by suction filtration at 80 °C in a vacuum oven to obtain hypromellose acetate succinate.

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com