Glass fiber reinforced plastic composite material and composite process

A composite material and composite technology technology, applied in the field of FRP composite materials and composite technology, can solve the problems of high cost, unbearable stripping of sheet tools, and affecting the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

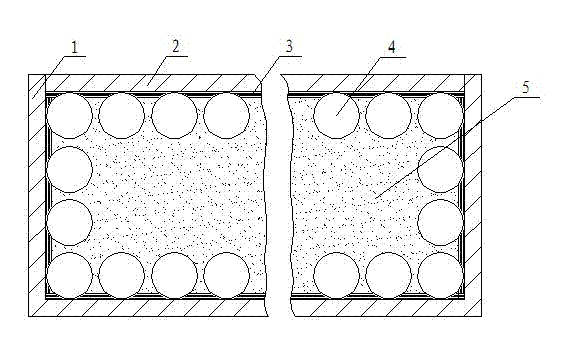

[0016] In conjunction with the accompanying drawings, the FRP composite material of the present invention and its composite process are described in detail:

[0017] As shown in the figure, the FRP composite material of the present invention is a FRP composite material composed of FRP organic glass steel, FRIM inorganic glass steel and interface materials. The FRP organic glass steel is coated on the surface of FRIM inorganic glass steel, and resin is coated between the two And lay the interface material, the interface material is aluminum oxide hollow balls with a diameter of 3-5mm.

[0018] Above-mentioned composite material composite technology is:

[0019] a. Form FRP plexiglass box-shaped part 1 and FRP plexiglass surface 2 respectively;

[0020] b. Brush a layer of resin 3 on the inner surface of the FRP organic glass steel box 1 and the panel FRIM inorganic glass steel 5, and lay a layer of aluminum oxide hollow spherical interface material 4 with a diameter of 3-5mm o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com