Oil-based stuck freeing agent composition for drilling fluid and preparation method for oil-based stuck freeing agent composition

The technology of an oil-based card releasing agent and composition is applied in the field of oil drilling, which can solve the problems of hindering the penetration of the card releasing agent, prolonging the card releasing time, and low success rate of card releasing, and achieving stable card releasing efficiency and good card releasing effect. , the effect of high card release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh each component according to the following ratio:

[0032]

[0033] Add each component to the reaction kettle, heat to 65°C, stir for 120 minutes, and cool to obtain the desired card-releasing agent.

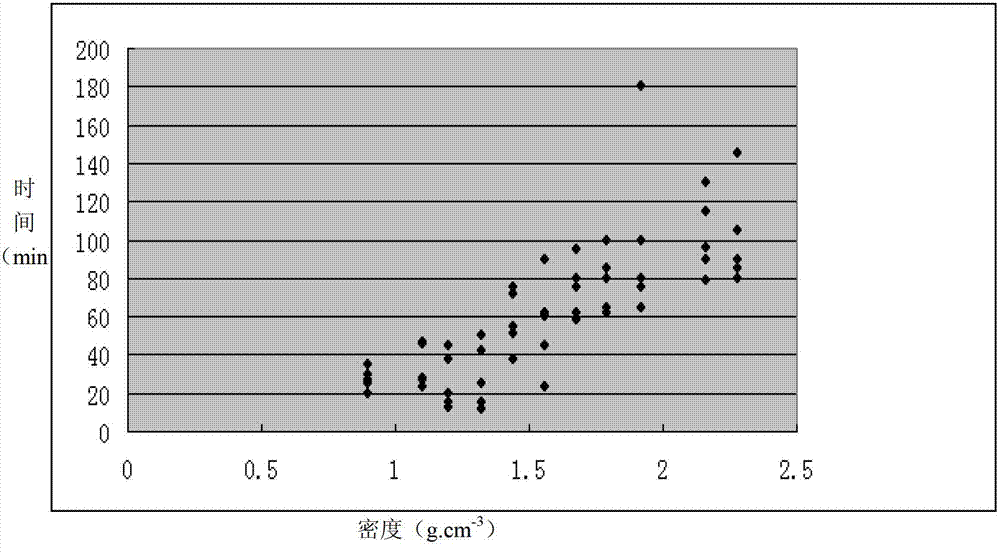

[0034] The card-releasing solution prepared by the obtained card-releasing agent has a card-freeing time reaching figure 1 Within the range shown, the suspension stability of the card-releasing solution meets the requirements.

Embodiment 2

[0036] Weigh each component according to the following ratio:

[0037]

[0038] Add each component to the reaction kettle, heat to 95°C, stir for 180 minutes, and cool to obtain the desired card-releasing agent.

[0039] The card-releasing solution prepared by the obtained card-releasing agent has a card-freeing time reaching figure 1 Within the range shown, the suspension stability of the card-releasing solution meets the requirements.

Embodiment 3

[0041] Weigh each component according to the following ratio:

[0042]

[0043]

[0044] Add each component to the reaction kettle, heat to 75°C, stir for 100 minutes, and cool to obtain the desired card-releasing agent.

[0045] The card-releasing solution prepared by the obtained card-releasing agent has a card-freeing time reaching figure 1 Within the range shown, the suspension stability of the card-releasing solution meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com