Alcohol-based fuel fan-free gasification furnace core

A technology of alcohol-based fuel and gasifier, which is applied in the field of stoves and stoves, and can solve problems such as the need for fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

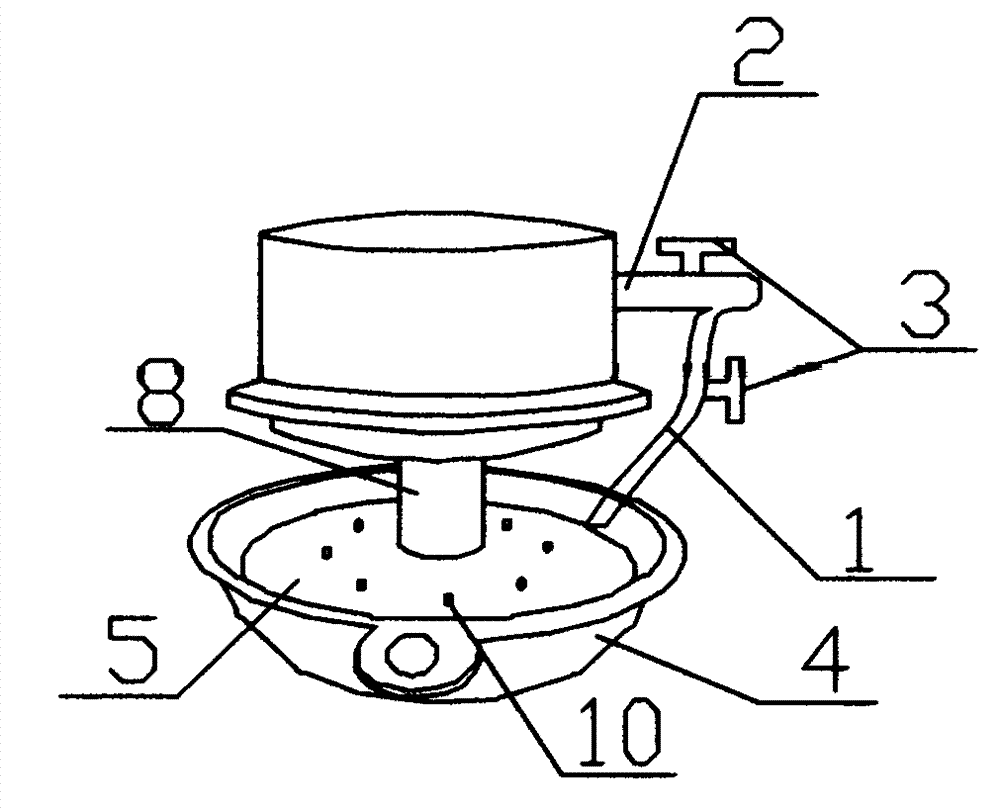

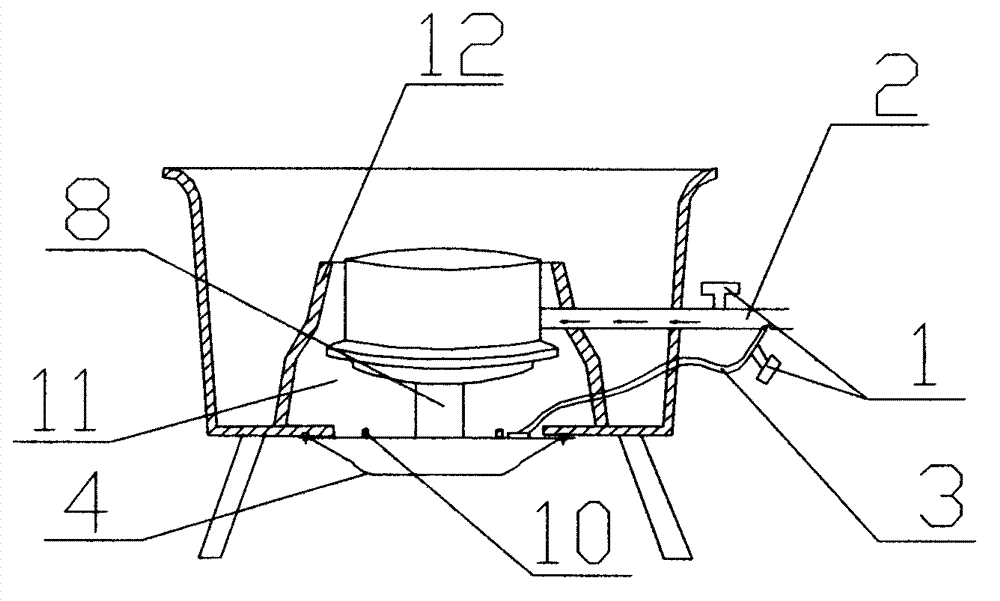

[0021] The alcohol-based fuel fanless gasification furnace core of the present invention is characterized in that it is composed of a fuel supply device, a fuel gasification device and a combustion device, and the furnace core is installed at the center bottom of the furnace cover 12 .

[0022] The fuel supply device is that the fuel switch controls the fuel oil pipe to enter the fuel, and the fuel oil pipe is divided into a preheating oil pipe 1 and a pressurized oil pipe 2, and a switch 3 is set respectively, and the preheating oil pipe flows to the oil pan 5 of the third gasification chamber 4 , The pressurized oil pipe 2 communicates with one end of the first gasification chamber.

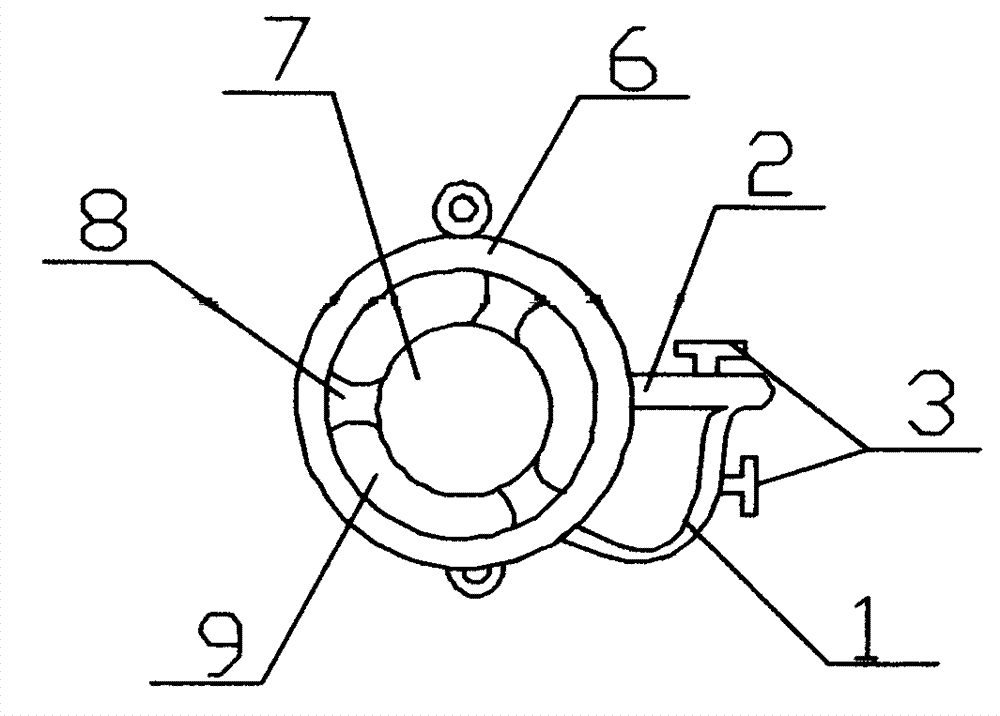

[0023] The fuel gas gasification device is composed of a hollow annular cylindrical first gasification chamber 6 , a hollow cylindrical second gasification chamber 7 and a hollow oil pan 5 and a third gasification chamber 4 .

[0024] The first gasification chamber 6 communicates with the secon...

specific Embodiment 2

[0030] The alcohol-based fuel fanless gasification furnace core of the present invention is characterized in that it is composed of a fuel supply device, a fuel gasification device and a combustion device, and the furnace core is installed at the center bottom of the furnace cover 12 .

[0031] The fuel supply device is that the fuel switch controls the fuel oil pipe to enter the fuel, and the fuel oil pipe is divided into a preheating oil pipe 1 and a pressurized oil pipe 2, and a switch 3 is set respectively, and the preheating oil pipe flows to the oil pan 5 of the third gasification chamber 4 , The pressurized oil pipe 2 communicates with one end of the first gasification chamber.

[0032] The fuel gas gasification device is composed of a hollow annular cylindrical first gasification chamber 6 , a hollow cylindrical second gasification chamber 7 and a hollow oil pan 5 and a third gasification chamber 4 .

[0033] The first gasification chamber 6 communicates with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com