Coal mine ventilation air methane preheating catalytic oxidation device with hot air recirculation function

A catalytic oxidizer and recirculation technology, applied in chemical instruments and methods, chemical/physical processes, dispersed particle separation, etc., can solve the problems of low heat recovery efficiency and high exhaust heat loss, and achieve low heating and starting power consumption. The effect of increasing the rate of temperature increase and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

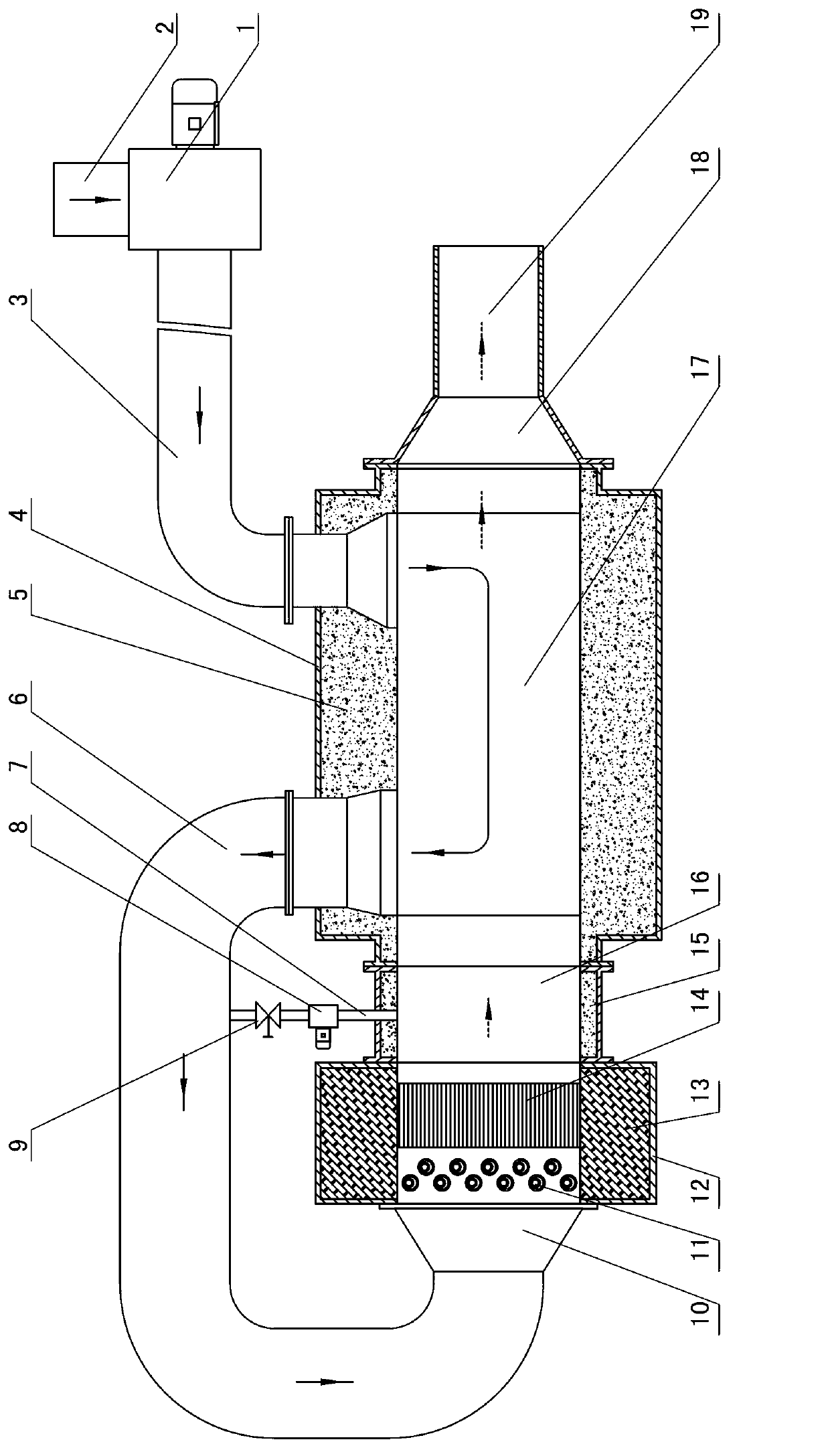

[0014] exist figure 1 In the shown embodiment: the exhaust air supply system includes a blower 1, a first exhaust air conveying pipeline 2, and a second exhaust air conveying pipeline 3, wherein the output end of the first exhaust air conveying pipeline 2 is connected through the blower 1 The second exhaust air conveying pipeline 3; the reaction chamber is surrounded by the reaction chamber shell 12 provided with the second insulation layer 13, and the electric heating wire 11 and the catalyst ceramic layer 14 are arranged in sequence along the gas flow direction in the reaction chamber; preheating The device 17 adopts a partition-type gas-gas heat exchanger, and there is a first insulation layer 5 between the preheater 17 and the preheater shell 4, wherein the exhaust air inlet of the preheater 17 and the second exhaust air conveying pipeline 3 The exhaust air outlet of the preheater 17 communicates with the inlet of the reaction chamber through the hot air connecting pipe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com