Collecting agent and ore selection method of jordisite

A beneficiation method and a technology for colloidal sulfur molybdenum ore, applied in the field of collectors, can solve problems such as difficulty in beneficiation of colloidal sulfur molybdenum ore, and achieve the effects of cleanliness, environmental protection, good stability, low dosage of chemicals, and increased flotation recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

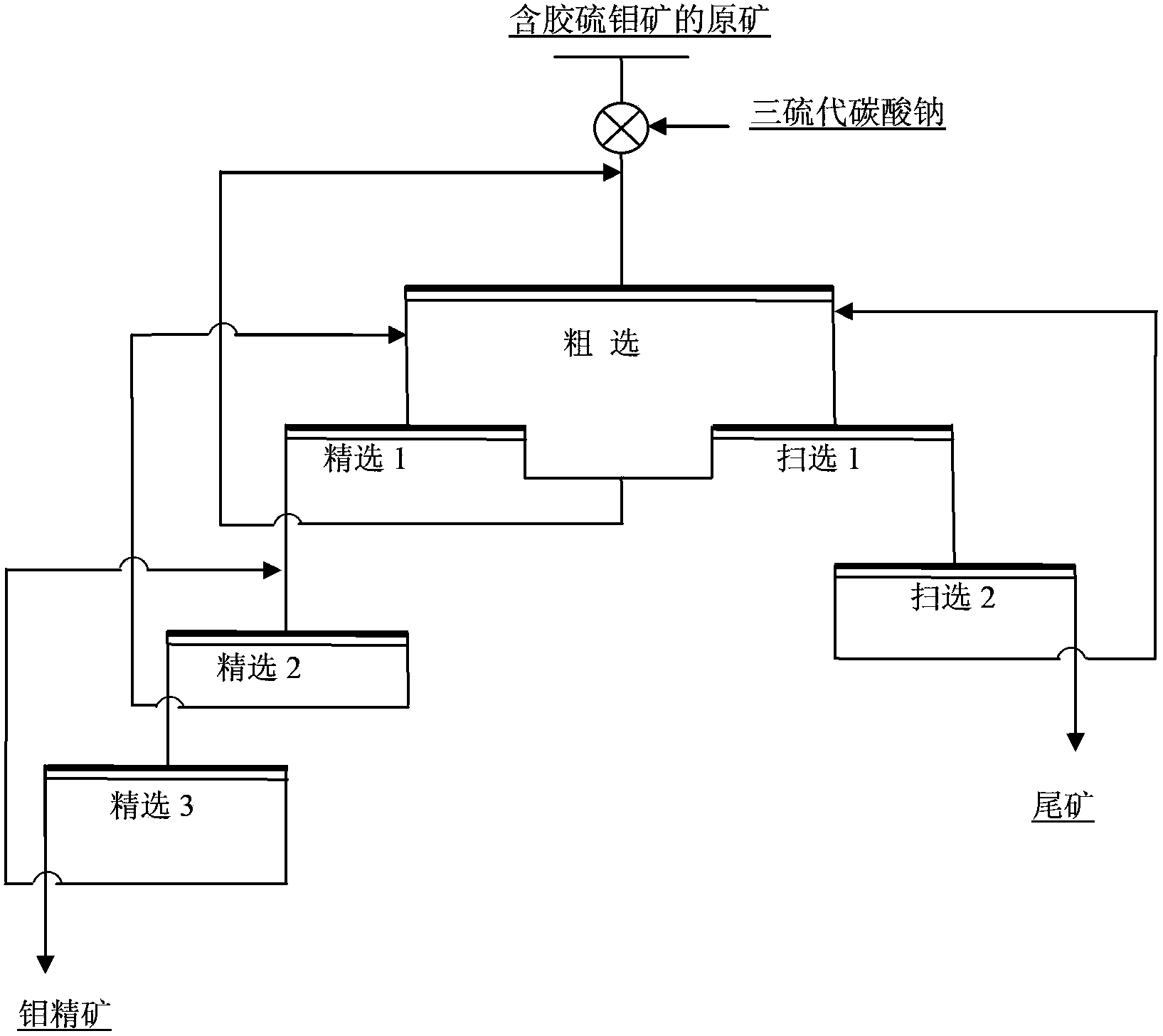

Method used

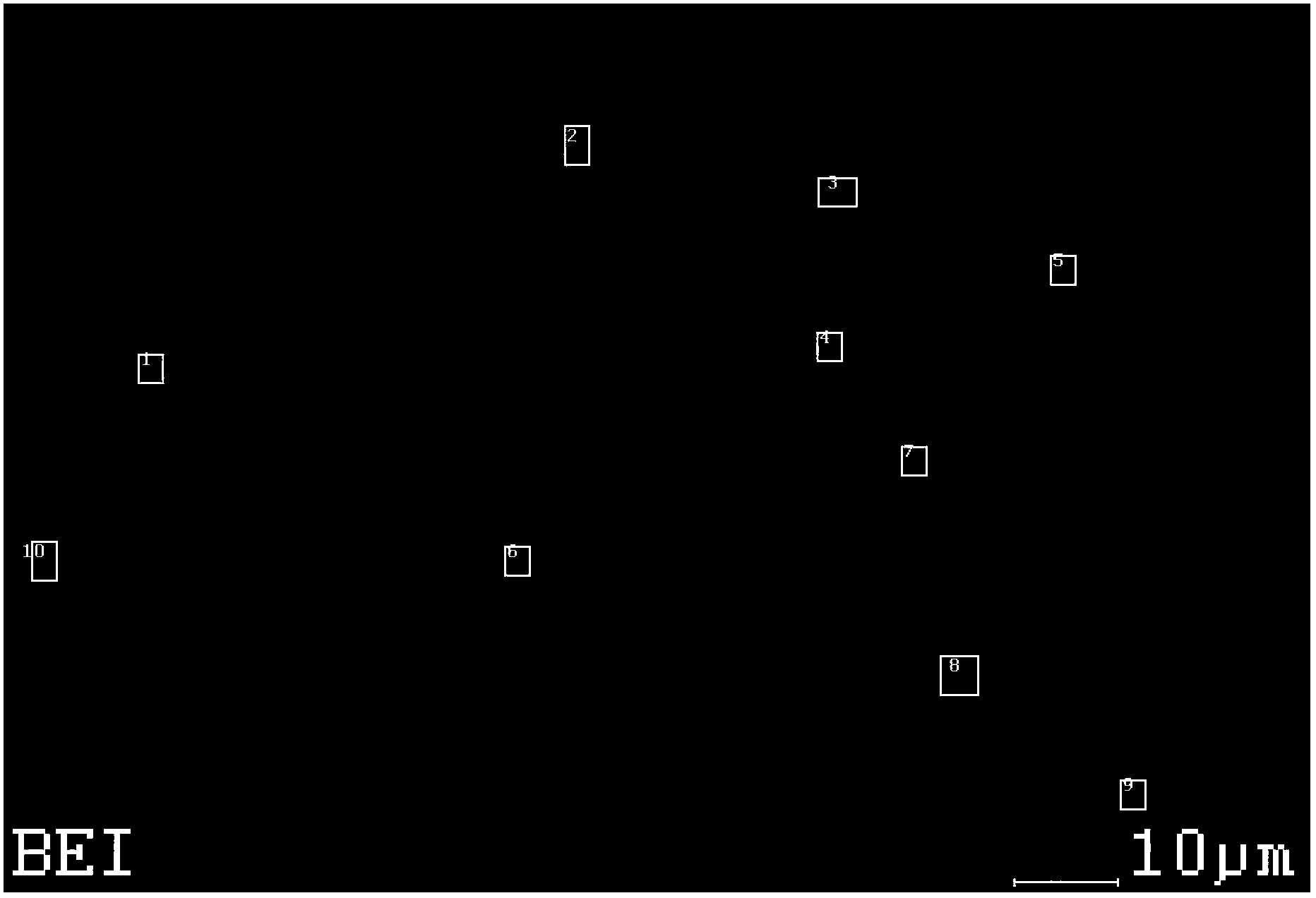

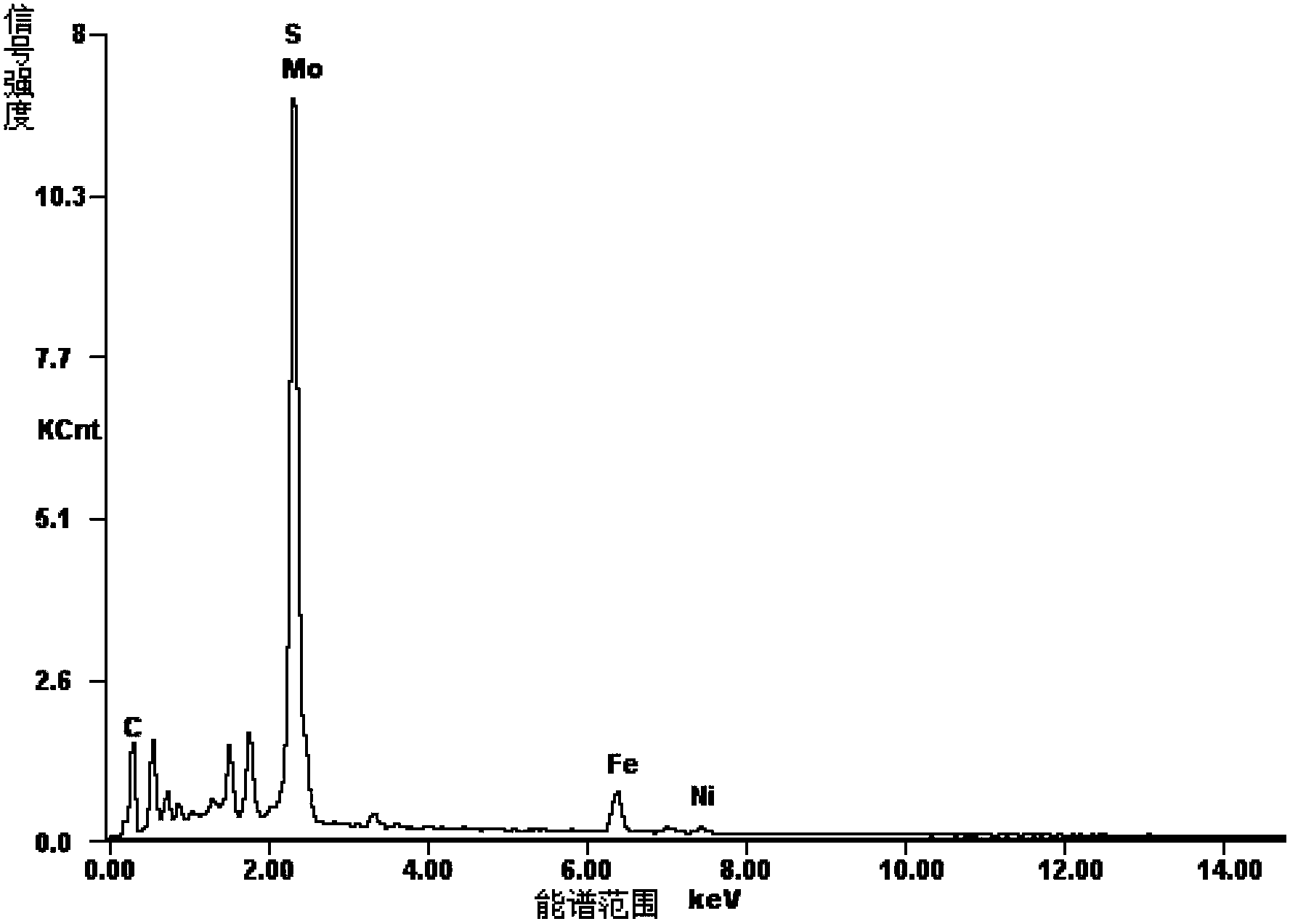

Image

Examples

Embodiment 1

[0035] Inhibitor 1 used in Example 1 and Example 5: water glass + modified starch was mixed in a weight ratio of 3:1, and then prepared into an aqueous solution with a mass concentration of 8%.

Embodiment 2

[0036] Inhibitor 2 used in Example 2 and Example 6: Sodium lignosulfonate was prepared into an aqueous solution with a mass concentration of 8%.

Embodiment 3

[0037] Inhibitor 3 used in Example 3 and Example 7: sodium hexametaphosphate was prepared into an aqueous solution with a mass concentration of 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com