Novel quaternary layered double hydroxide (LDHs), its preparation method and application thereof

A new type of hydrotalcite technology, applied in the field of material science, can solve the problems of synthetic quaternary LDHs that have not been reported, and achieve the effects of ensuring environmental protection, avoiding waste of raw materials, and efficient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

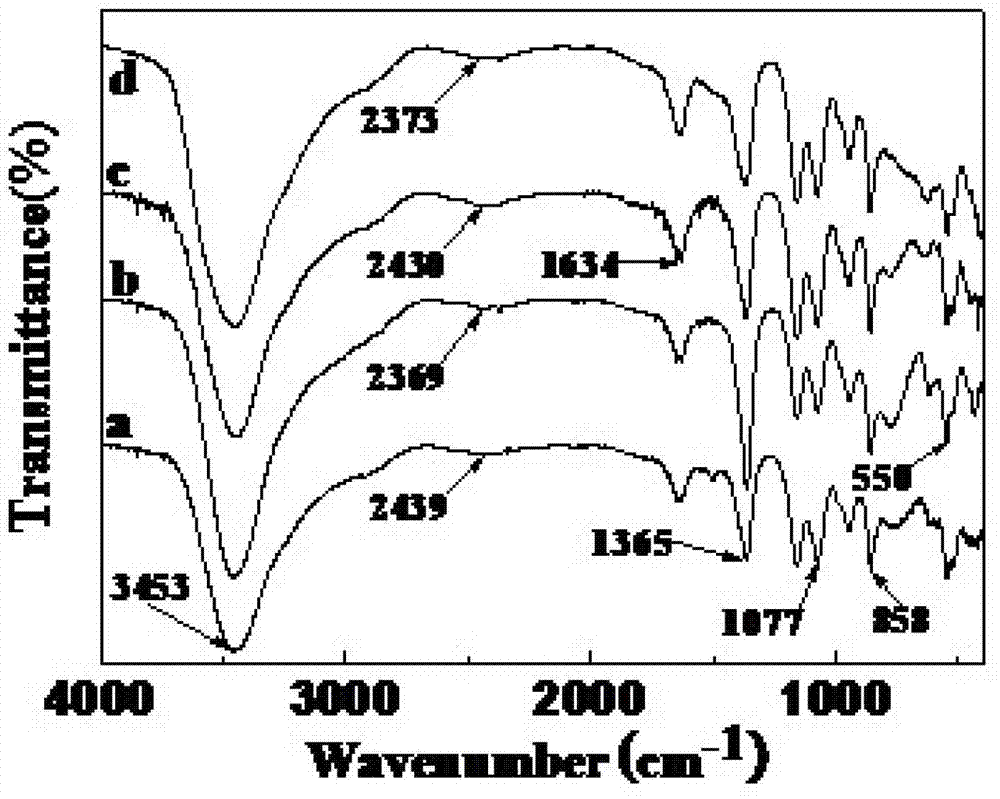

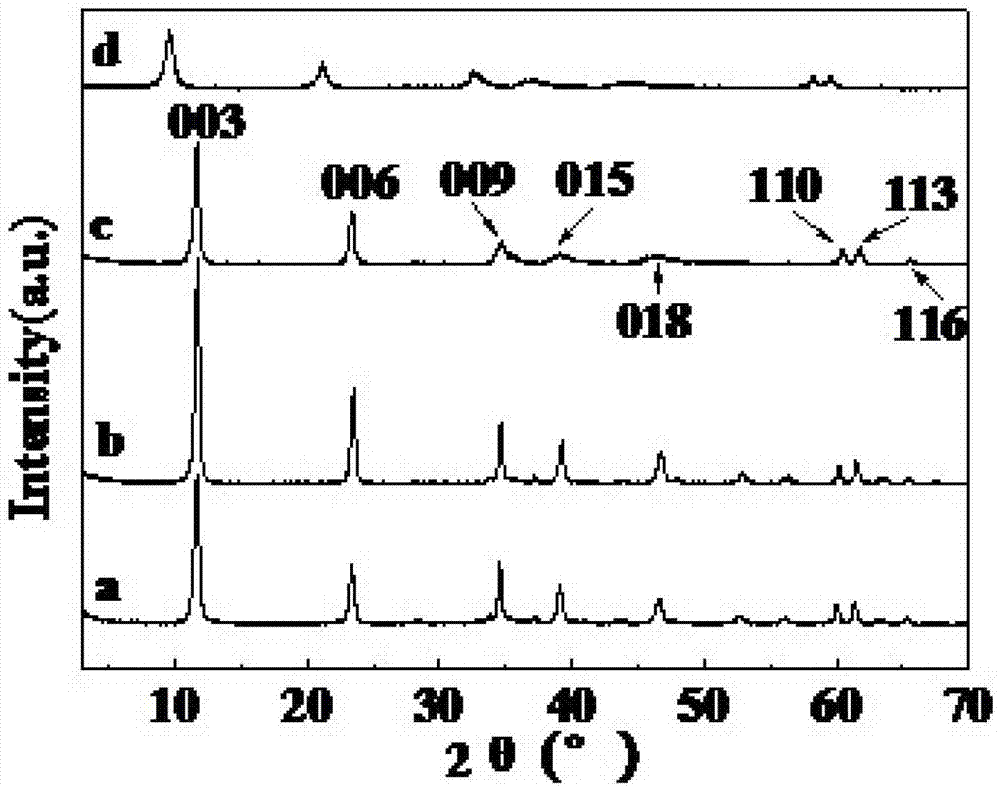

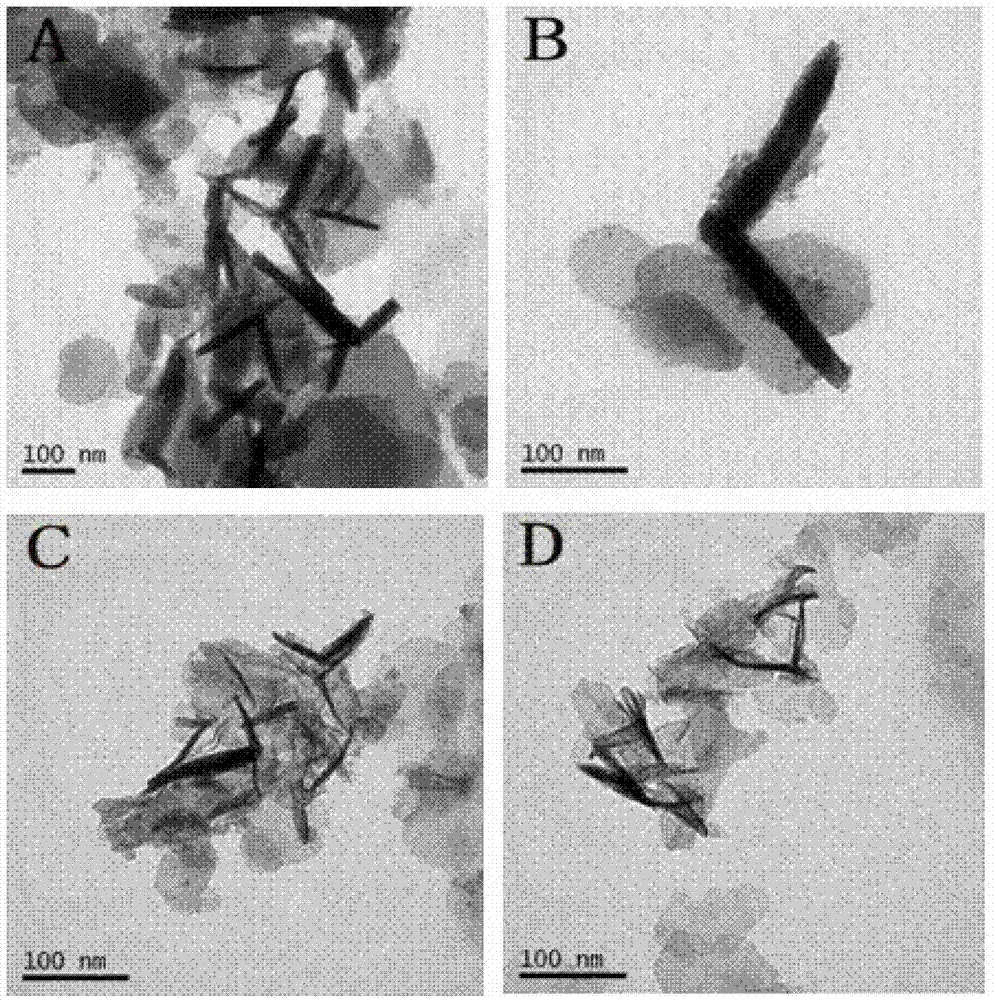

[0018] Take 0.065mol MgCl 2 ·6H 2 O, 0.535mol ZnCl 2 , 0.15mol AlCl 3 ·6H 2 O, 0.05mol FeCl 3 ·6H 2 O and 8.895g PEG were dissolved in deionized water to form mixed liquid A; another 1.28mol NaOH, 0.4mol NaOH 2 CO 3 Dissolved in deionized water to configure precipitant B.

[0019] Preparation: A and B solutions were magnetically stirred for 30 minutes and then ultrasonically treated for 15 minutes. Add the two mixtures into a self-made reactor and react quickly after high-pressure atomization; adjust the pH range of the system to keep it between 9-10, and finally place the obtained mixed slurry at a reflux temperature of 90°C Crystallize for 6h, filter, wash, and dry to obtain MgAlZnFe-CO 3 LDHs products.

Embodiment 2

[0021] Take 0.065mol MgCl 2 ·6H 2 O, 0.335mol ZnCl 2 , 0.15mol AlCl 3 ·6H 2 O, 0.05mol FeCl 3 ·6H 2 O and 7.051g PEG were dissolved in deionized water to configure mixed solution A; another 0.96mol NaOH, 0.4mol NaOH 2 CO 3 Dissolved in deionized water to configure precipitant B.

[0022]Preparation: A and B solutions were magnetically stirred for 30 minutes and then ultrasonically treated for 15 minutes. Add the two mixtures into a self-made reactor and react quickly after high-pressure atomization; adjust the pH range of the system to keep it between 9-10, and finally place the obtained mixed slurry at a reflux temperature of 90°C Crystallize for 6h, filter, wash, and dry to obtain MgAlZnFe-CO 3 LDHs products.

Embodiment 3

[0024] Take 0.32mol MgCl 2 ·6H 2 O, 0.08mol ZnCl 2 , 0.15mol AlCl 3 ·6H 2 O, 0.05mol FeCl 3 ·6H 2 O and 6.005g PEG were dissolved in deionized water to form mixed liquid A; another 0.96mol NaOH, 0.4mol NaOH 2 CO 3 Dissolved in deionized water to configure precipitant B.

[0025] Preparation: A and B solutions were magnetically stirred for 30 minutes and then ultrasonically treated for 15 minutes. Add the two mixtures into a self-made reactor and react quickly after high-pressure atomization; adjust the pH range of the system to keep it between 9-10, and finally place the obtained mixed slurry at a reflux temperature of 90°C Crystallize for 6h, filter, wash, and dry to obtain MgAlZnFe-CO 3 LDHs products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com