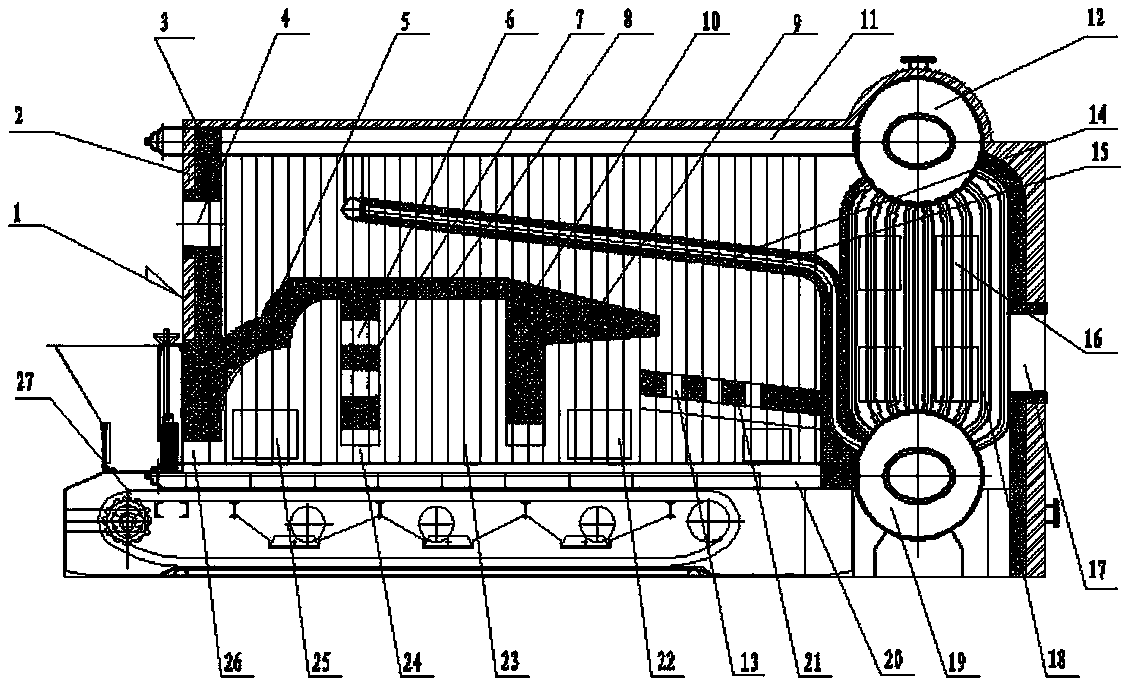

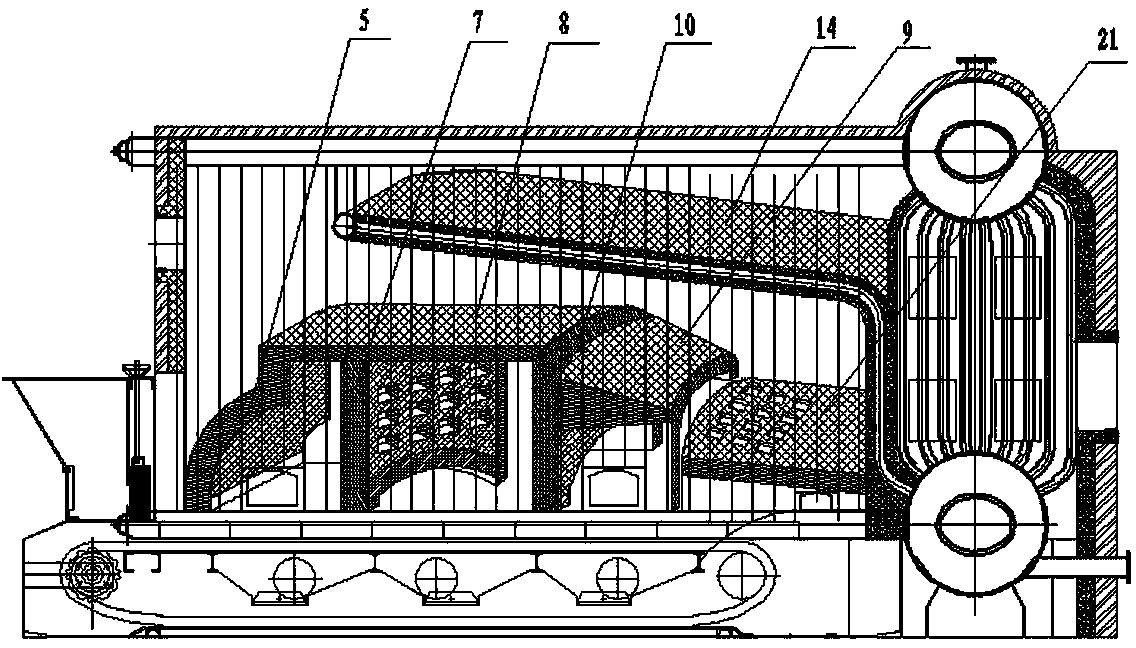

Chain type environment-friendly double-drum biomass particle gasifying burning hot-water boiler

A technology of biomass particles and double drums, which is applied in the field of boilers, can solve the problems that the smoke pipes cannot normally use the service life of the boiler, and achieve the effects of scientific and reasonable design technology, prolonging service life, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The chain-type double-drum biomass particle gasification combustion hot water environmental protection boiler includes a double-drum consisting of a furnace body 1, a chain grate 27, an upper drum 12 and a lower drum 19. The furnace body 1 is composed of a refractory cement layer 3 poured on the insulating material layer 2, and the furnace body 1 is sequentially provided with a preheating combustion closed arc arch 5 and an arc arch wall 7 with a mesh smoke hole 6 from the front. 1. A high-temperature radiation combustion arc arch wall 10 and a high-temperature radiation combustion closed top arch 8 connected to the tops of the two, an arc-shaped smoke return arch 9 is arranged at the rear of the high-temperature radiation combustion arc arch wall 10, and poured behind the arc-shaped smoke return arch The arc-shaped arch furnace 21 of the convective combustion by slag burn-out has a plurality of ash-falling and smoke-passing heating holes 13 on the top, and a slanted lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com