Soil thermal desorption rotary furnace testing system and testing method thereof

A test system and test method technology, applied in the field of contaminated soil remediation, can solve the problem of lack of reliable laboratory test system and test method for soil thermal desorption remediation technology, and achieve simple and convenient test method, low energy consumption, and convenient and quick replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

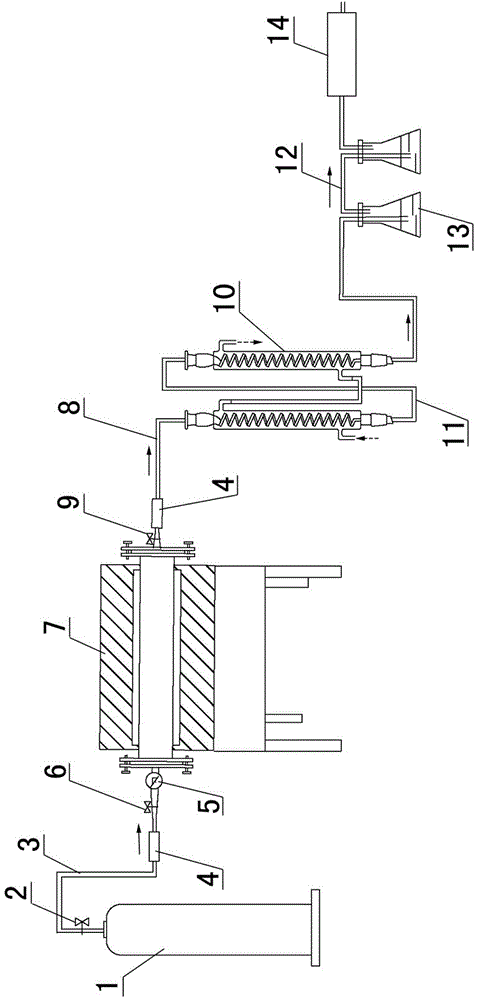

[0033] Examples see figure 1 As shown, this soil thermal desorption rotary furnace test system includes a carrier gas device, a rotary thermal desorption test device and a tail gas treatment device.

[0034] The gas-carrying device includes a nitrogen bottle 1, a pressure reducing valve 2 and an intake corrosion-resistant gas conduction hose 3, wherein the intake corrosion-resistant air conduction hose 3 is connected to the gas outlet of the nitrogen cylinder 1, and the pressure relief valve 2 is set On the intake corrosion-resistant air guide hose 3.

[0035] The rotary thermal desorption testing device includes a tubular rotary furnace 7, an air inlet air valve 6, a flowmeter 5 and an air outlet air pressure valve 9, and the inlet end of the tubular rotary furnace 7 is flanged to the flowmeter 5, The flow meter 5 is in communication with the air intake air valve 6, and the air intake air valve 6 is in communication with the corrosion-resistant air guide hose 3 in the air ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com