Quartz crystal fine tuning limiting plate moving device

A mobile device and limit plate technology, applied in electrical components, impedance networks, etc., can solve the problems of low work efficiency, unreasonable structural design of linear trimmers, etc., and achieve the effects of simple structure, reasonable design and flexible action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in combination with specific diagrams and specific examples, but it is not intended to limit the protection scope of the present invention.

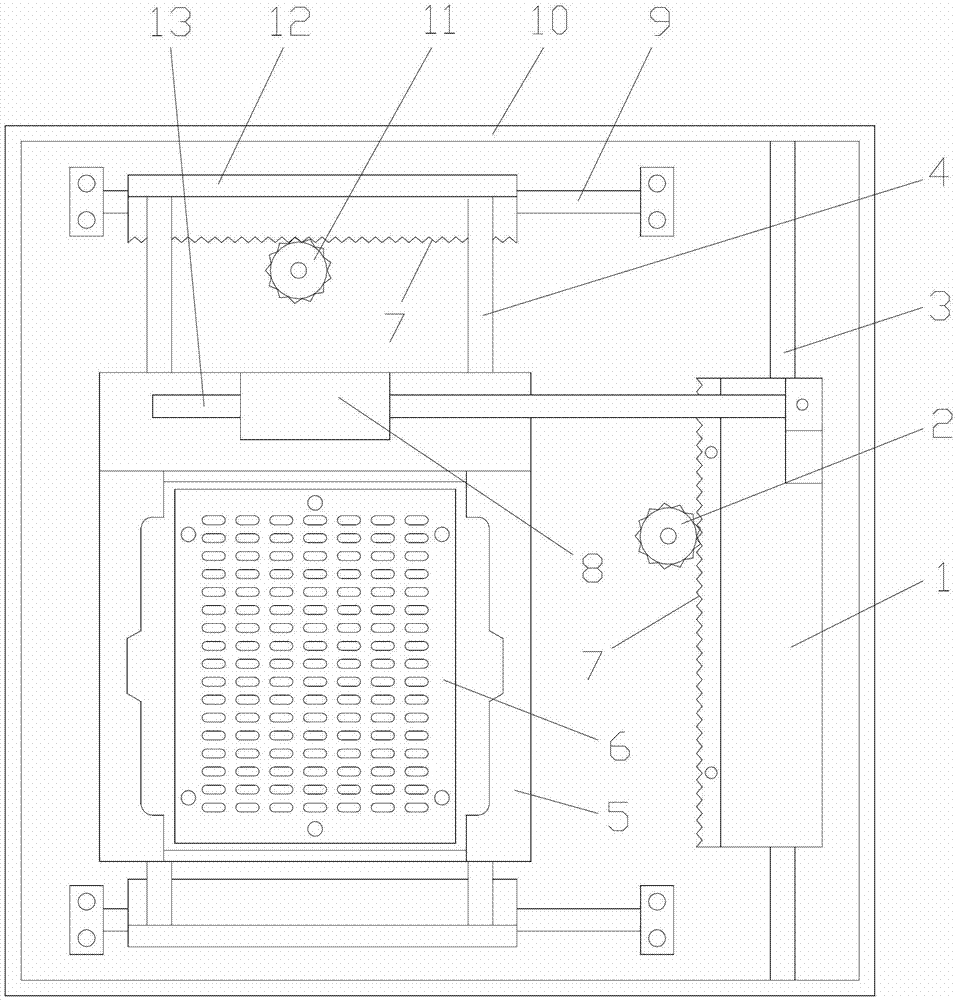

[0012] Please refer to figure 1 , a quartz crystal fine-tuning limit plate moving device, including a transverse guide mechanism and a longitudinal guide mechanism installed in the work box 10, the transverse guide mechanism includes two transverse guide rods 9 arranged in parallel, on the two transverse guide rods 9 Both are provided with laterally moving seats 12, wherein one of the laterally moving seats 12 is shaped on a bar-shaped tooth 7 to engage with the lateral transmission gear 11; the longitudinal guiding mechanism includes two longitudinally moving guide rods 4 and The longitudinally fixed guide rods 3 fixed in the working box body 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com