Film speaker and production method thereof

A manufacturing method and loudspeaker technology, applied in the direction of sensors, planar diaphragms, diaphragm structures, etc., to achieve the effect of simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

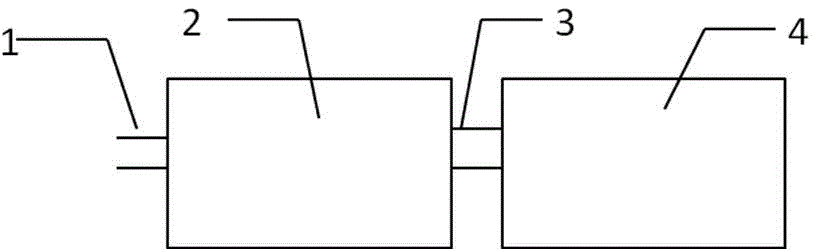

[0027] The output of the audio amplifier device 1 is a constant voltage output mode, and the output voltage is 70V and 100V, which can be switched in two gears.

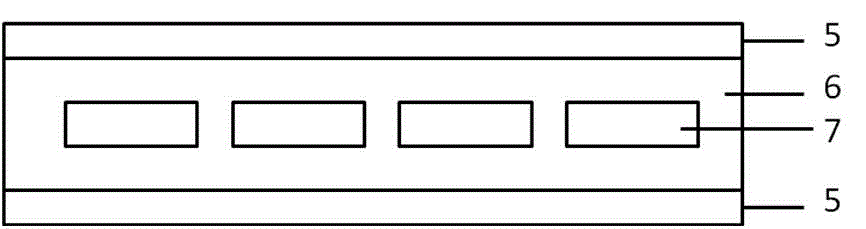

[0028] The specific preparation process of the flexible transparent electroacoustic conversion film 4 is as follows: (1) The 12.5um thick FEP film produced by DuPont Company is used as the raw material. First cut the FEP film into a 6cm*6cm sample film, and then use the embossing method to form an uneven pattern on the surface of the FEP sample film to obtain the second polymer film and the third polymer film described in the present invention. . The pattern of the embossing mold is a circular array pattern, the diameter of each circular pattern is 1mm, and the distance between the center points of two adjacent circular patterns is 1.2mm. (2) The second polymer film and the third polymer film are laminated together, and melted and thermally bonded at a temperature of 300° C. to obtain the fourth polymer film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com