Anti-glare film, manufacturing method of same, polarizing plate and image dislay device

An anti-glare film and a technology for its manufacturing method, which are applied in polarizing elements, nonlinear optics, optics, etc., can solve the problems of insufficient impact resistance of the anti-glare layer, and achieve a high level of anti-glare effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] First, triacetyl cellulose (manufactured by Fujifilm Co., Ltd., thickness 80 μm) was prepared as a translucent substrate.

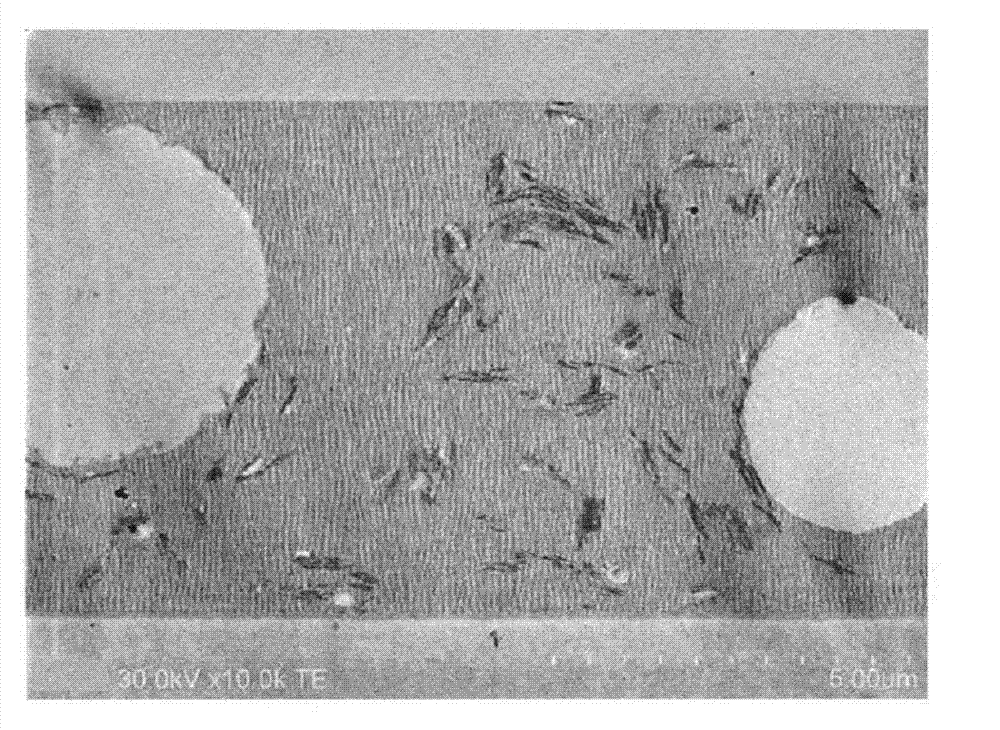

[0166] Next, as a radiation-curable adhesive, a mixture of pentaerythritol triacrylate (PETA), dipentaerythritol hexaacrylate (DPHA) and acetic acid-cellulose propionate (SAP) was used (mass ratio; PETA / DPHA / SAP =82 / 7 / 11) (refractive index 1.51); As a photopolymerization initiator, use 1-hydroxyl-cyclohexyl-phenyl-ketone: Irgacure 184 (manufactured by BASF) (100 parts by mass relative to the solid content of the adhesive 3 parts by mass); making it contain 6.0 parts by mass of low-crosslinked acrylic particles (refractive index 1.49, average particle diameter 5.0 μm) as organic fine particles (A) relative to 100 parts by mass of the radiation-curable adhesive, 5.0 parts by mass of polystyrene particles (refractive index 1.59, average particle diameter 3.5 μm) as microparticles (B) relative to 100 parts by mass of the radiation-curable adhesive, 100...

Embodiment 2~11、 comparative example 1~5

[0170] The type of organic microparticles (A) and microparticles (B) added to the coating liquid, the type and content of layered inorganic compounds, the presence or absence of surfactants, and the ratio of (coating liquid supply amount / coating amount) for example As shown in Table 1, except the above, it carried out similarly to Example 1, and produced the antiglare film.

[0171] Table 1

[0172]

[0173] Details of symbols shown in the organic fine particles (A), fine particles (B), layered inorganic compounds, and solvents shown in Table 1 are as follows. In addition, in Table 1, content of a layered inorganic compound shows content (mass part) with respect to 100 mass parts of radiation-curable adhesives.

[0174] (organic particle A)

[0175] A: Highly cross-linked acrylic particles (refractive index 1.49, average particle diameter 5.0 μm, manufactured by Soken Chemical Co., Ltd.)

[0176] B: Low-crosslinked acrylic particles (refractive index 1.49, average partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com