Circulating feeding distributer with no guide plate

A technology of feed distributor and distributor, applied in the direction of feeding device, fractionation, separation method, etc., can solve the problems of deflector vibration damage, complex and changeable fluid flow form, unfavorable flow field uniform distribution, etc., to avoid Effects of eddy current, damage reduction, and pressure drop reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

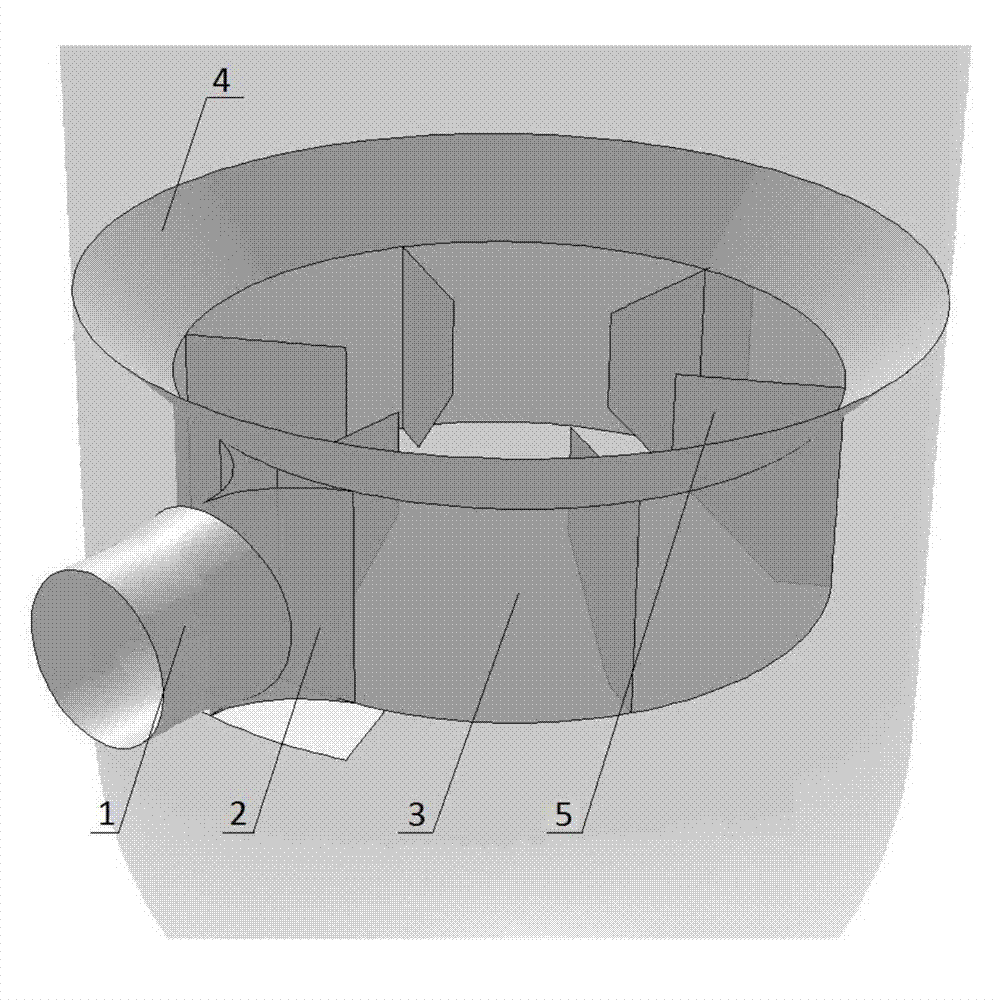

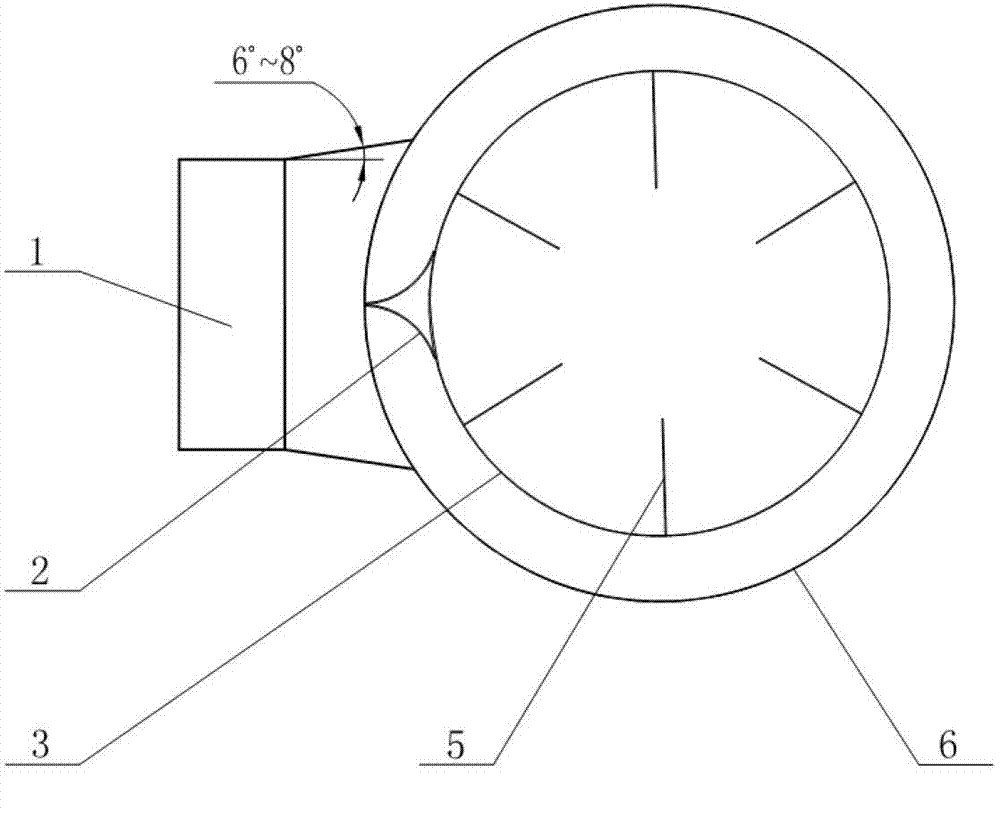

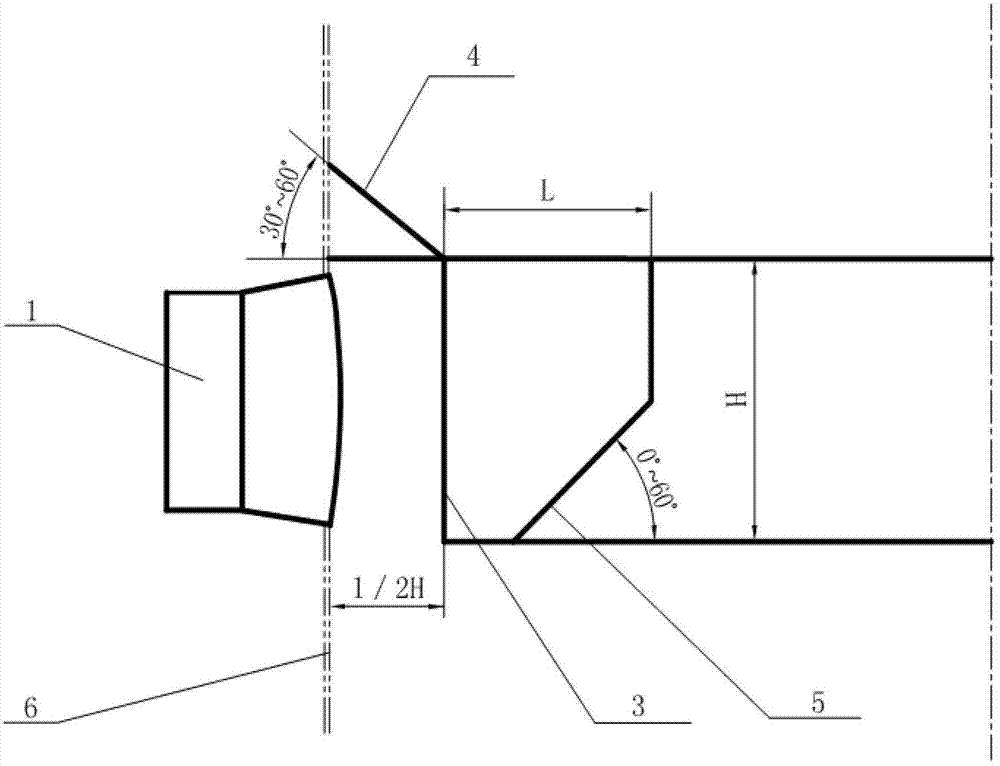

[0020] The circulating feed distributor without deflector of the present invention mainly includes a feed pipe 1 , an inlet deflector 2 , an inner sleeve 3 , a deflector cover 4 and an anti-swirl flow baffle 5 . The upper cover plate and the inner sleeve form an annular space with a closed top and an open bottom. The anti-swirl flow baffle is arranged on the inner side of the inner sleeve, fixed on the inner sleeve, and also acts as a reinforcing rib.

[0021] Such as figure 1 The feed pipe 1 shown is a diffuser tube, and a diffuser section with an expansion angle of 6°~8° is added to the outlet of the straight section of the diffuser tube, and the outlet of the diffuser end is welded to the tower wall. The inlet deflector 2 is a pair of streamlined deflectors, which are welded in a herringbone structure. The cover plate 5 is a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com