Cement-based self-leveling mortar

A self-leveling mortar and cement-based technology, applied in the field of building materials, can solve problems such as high prices, cracks, and high costs, and achieve the effects of improving volume stability, uniform quality, and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

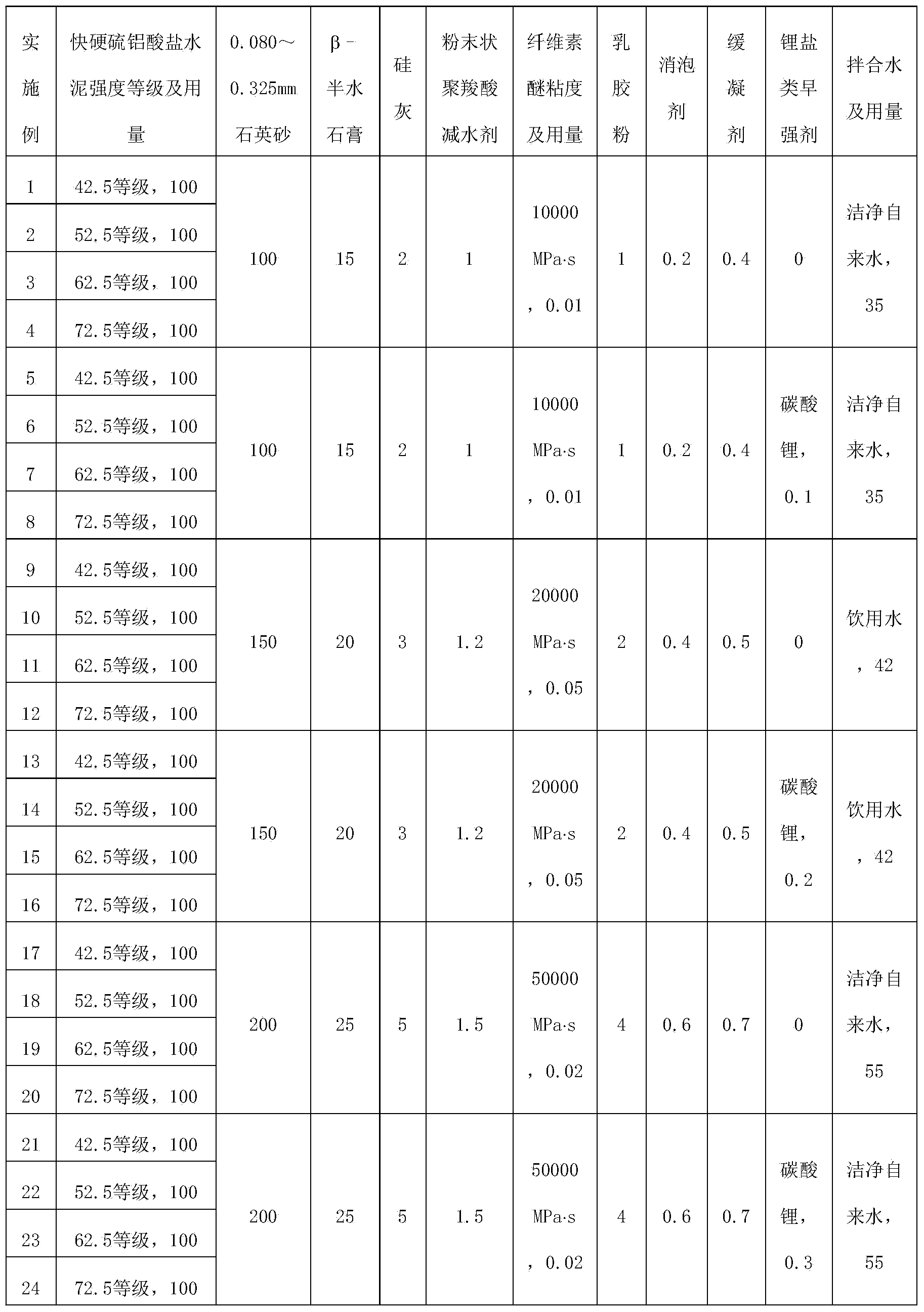

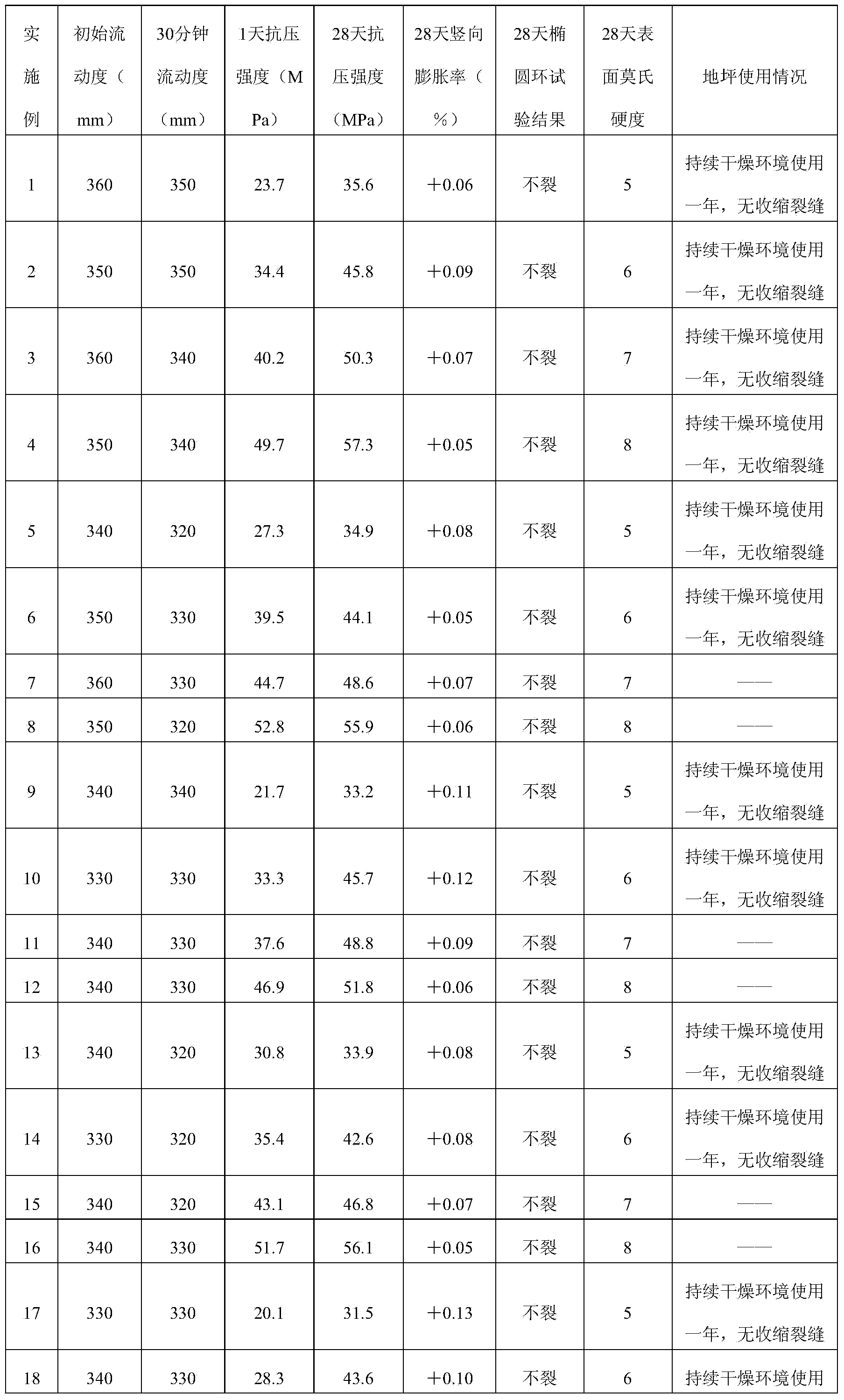

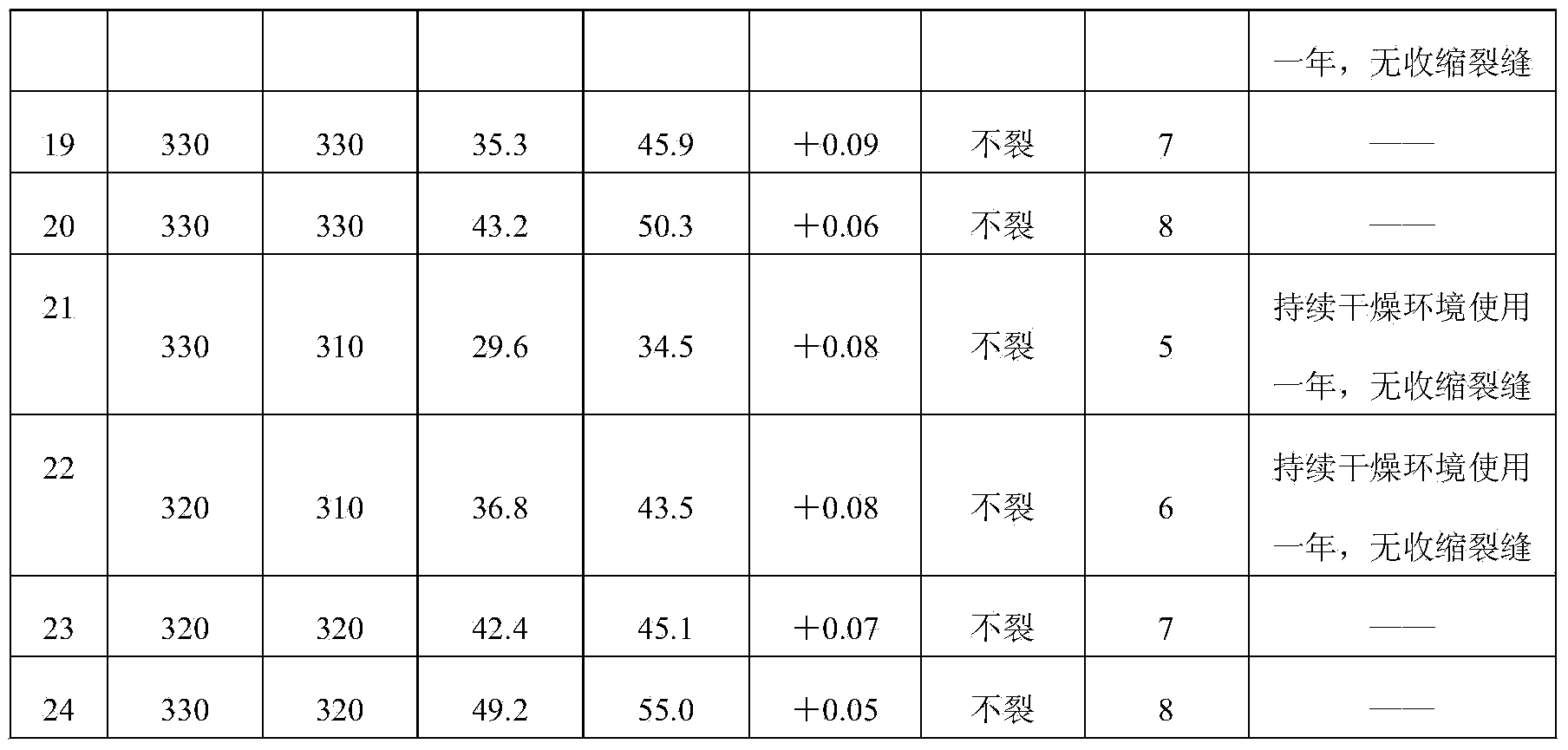

[0015] The raw material composition of the cement-based floor mortar of each embodiment and the mixing water consumption during use are shown in Table 1, the performance measured by the freshly mixed mortar after the cement-based floor mortar of different embodiments is mixed and the use of the floor obtained by it The situation is shown in Table 2. The fluidity test method is shown in Appendix A.0.2 of GB / T 50448-2008 "Technical Specifications for the Application of Cement-based Grouting Materials"; the 30-minute fluidity is the working time during construction; the compressive strength test method is shown in GB / T 50448-2008 "Technical Specifications for Application of Cement-Based Grouting Materials" Appendix A.0.4; test methods for vertical expansion rate and elliptical ring cracking test see Appendix A.0.5 of GB / T 50448-2008 "Technical Specifications for Application of Cement-based Grouting Materials" , and the surface hardness was measured with a Mohs hardness tester.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com