Ecological tanning method of Tan sheep skin

A Tan sheep skin and tanning technology, applied in the field of Tan sheep skin ecological tanning, can solve the problems of Tan sheep skin export inconvenience, environmental pollution, environmental pollution by chrome tanning waste liquid, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

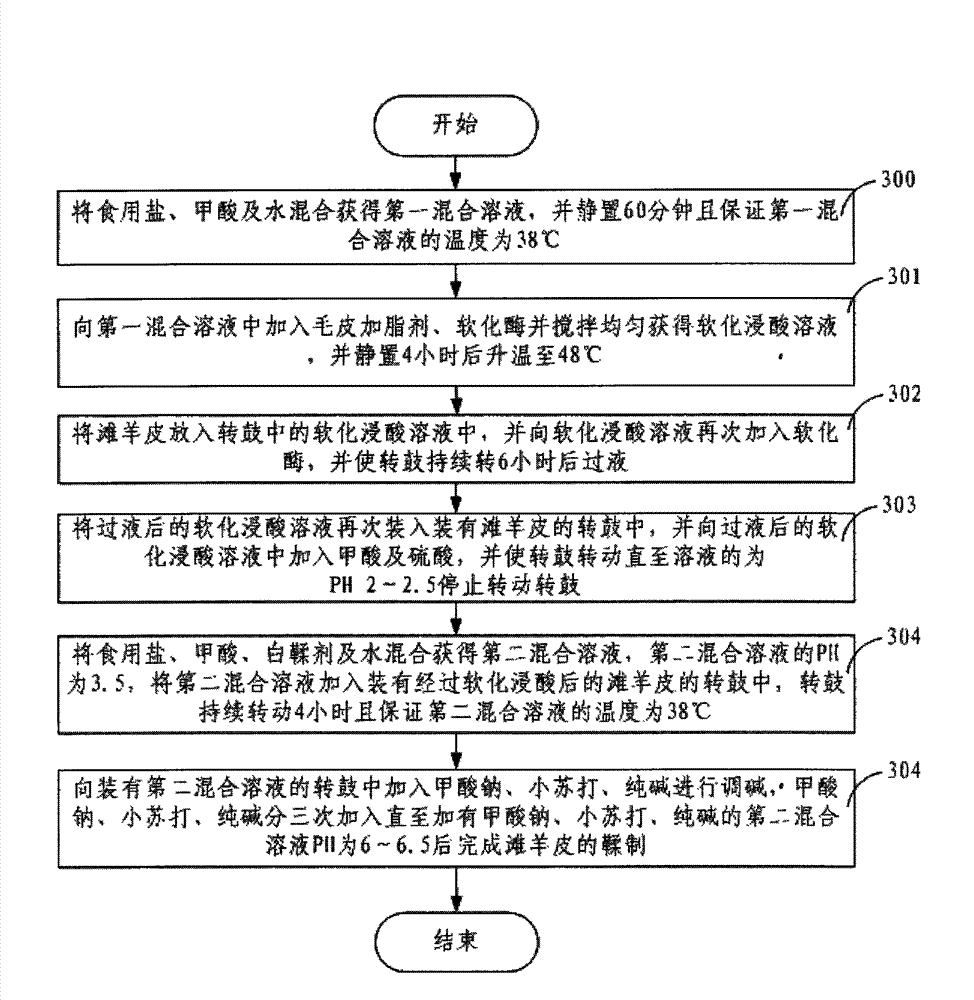

[0017] Please see also figure 1 , Tan sheepskin ecological tanning method, comprises the following steps:

[0018] Step S300, mixing edible salt, formic acid and water to obtain a first mixed solution, and standing for 60 minutes to ensure that the temperature of the first mixed solution is 38°C.

[0019] Step S301, add fur fatliquoring agent and softening enzyme to the first mixed solution and stir evenly to obtain a softened pickling solution, and let it stand for 4 hours and then raise the temperature to 48°C, wherein the concentration of edible salt is 60g / L, and the concentration of formic acid is 2g / L, the concentration of fur fatliquoring agent is 2g / L, and the concentration of softening enzyme is 1g / L.

[0020] Step S302, put the Tan sheepskin into the softening pickling solution in the drum, and add softening enzyme to the softening pickling solution again, and let the drum continue to rotate for 6 hours to pass through the liquid, wherein the softening enzyme conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com