Nickel electroplating solution and electroplating method thereof

A technology of nickel electroplating solution and conductive salt is applied in the field of nickel electroplating solution and its electroplating to achieve the effect of improving covering ability, strong anti-corrosion ability and good covering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

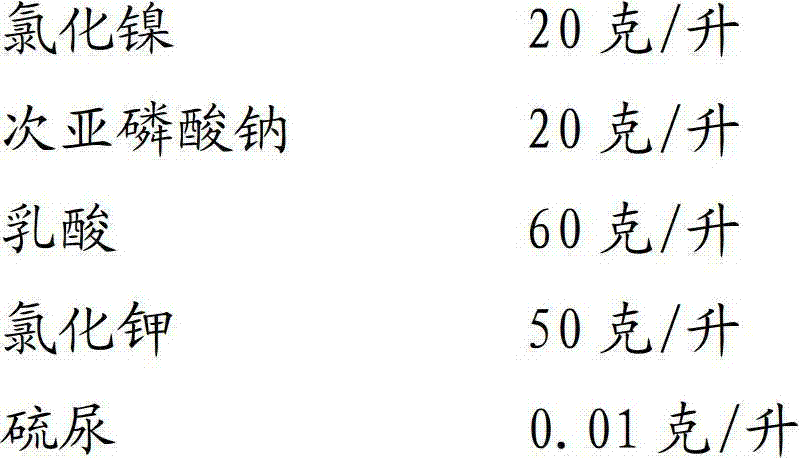

[0032] Plating solution composition:

[0033]

[0034] The balance is water

[0035] Electroplating method: use a thin-walled iron pipe with an inner diameter of Ф10X100mm, and conduct an electroplating test in a 1000ml beaker. The conditions are: temperature 50°C, DC current 1 ampere, electroplating for 8 minutes, nickel plate for the anode, and nickel-plated iron pipe A1.

[0036] Evaluation of electroplating effect: Observe the length of the nickel layer plated on the inner wall of the iron pipe to be 100mm, and then evaluate the covering ability of the plating solution. The nickel-plated iron pipe A1 was subjected to a neutral salt spray test for 8 hours, and no corrosion of the nickel layer was found.

Embodiment 2

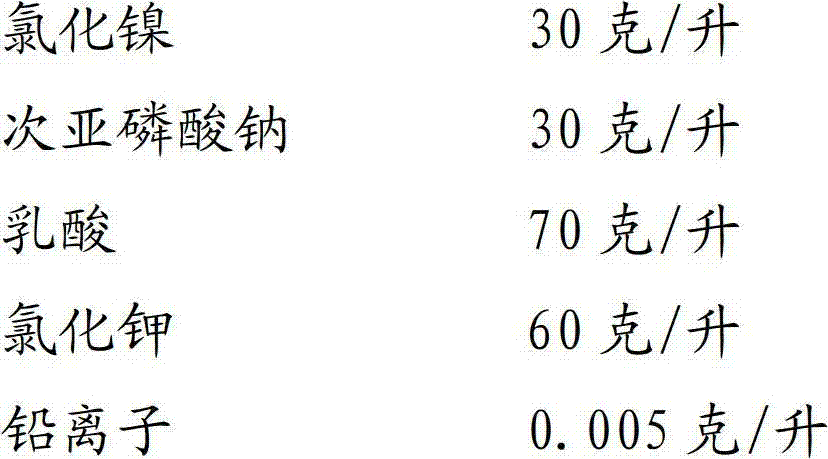

[0038] Plating solution composition:

[0039]

[0040] The balance is water

[0041] Electroplating method: use a thin-walled iron pipe with an inner diameter of Ф10X100mm, and conduct an electroplating test in a 1000ml beaker. The conditions are: temperature 55°C, DC current 0.5 ampere, electroplating for 7 minutes, and anode using a nickel plate to obtain a nickel-plated iron pipe A2.

[0042] Evaluation of electroplating effect: Observe the length of the nickel layer plated on the inner wall of the iron pipe to be 100mm, and then evaluate the covering ability of the plating solution. The nickel-plated iron pipe A2 was subjected to a neutral salt spray test for 7 hours, and no corrosion of the nickel layer was found.

Embodiment 3

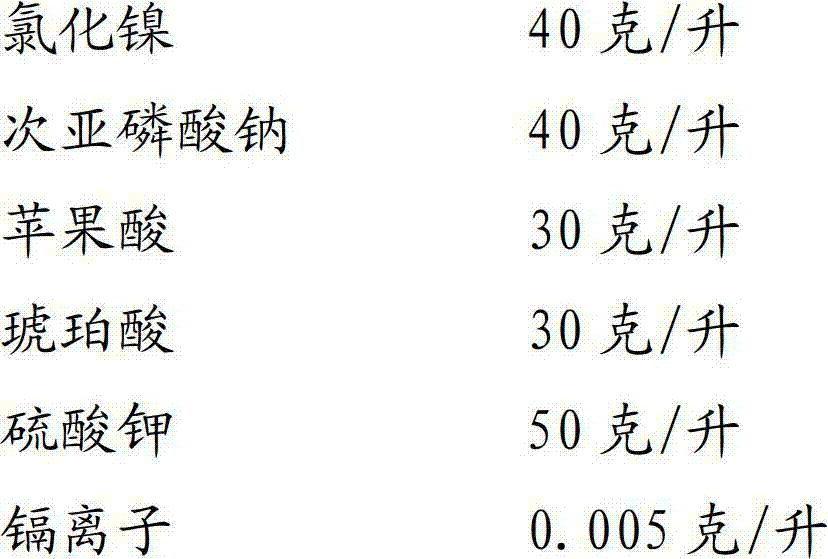

[0044] Plating solution composition:

[0045]

[0046] The balance is water

[0047] Electroplating method: use a thin-walled iron pipe with an inner diameter of Ф10X100mm, and conduct an electroplating test in a 1000ml beaker. The conditions are: temperature 55°C, DC current 0.5 ampere, electroplating for 7 minutes, and anode using a nickel plate to obtain a nickel-plated iron pipe A3.

[0048] Evaluation of electroplating effect: Observe the length of the nickel layer plated on the inner wall of the iron pipe to be 100mm, and then evaluate the covering ability of the plating solution. The nickel-plated iron pipe A3 was subjected to a neutral salt spray test for 7 hours, and no corrosion of the nickel layer was found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com