Method for manufacturing flexible IGZO (In-Ga-Zn-O) thin film transistor

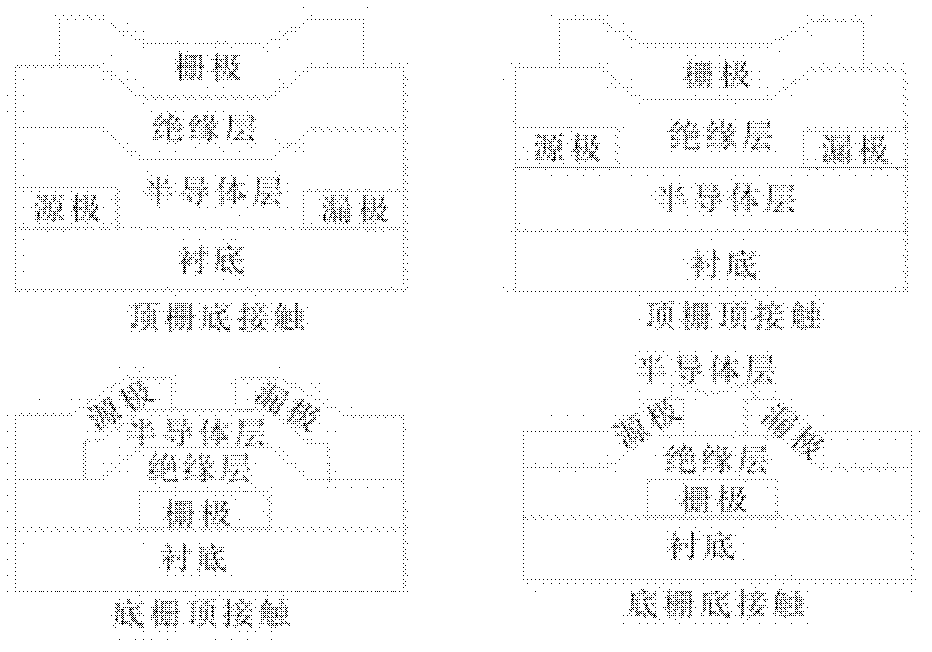

A thin-film transistor and flexible technology, applied in the field of microelectronics, can solve the problems that cannot be copied to flexible substrates, and the insulating layer cannot be prepared under the optimal process (300℃-350℃)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

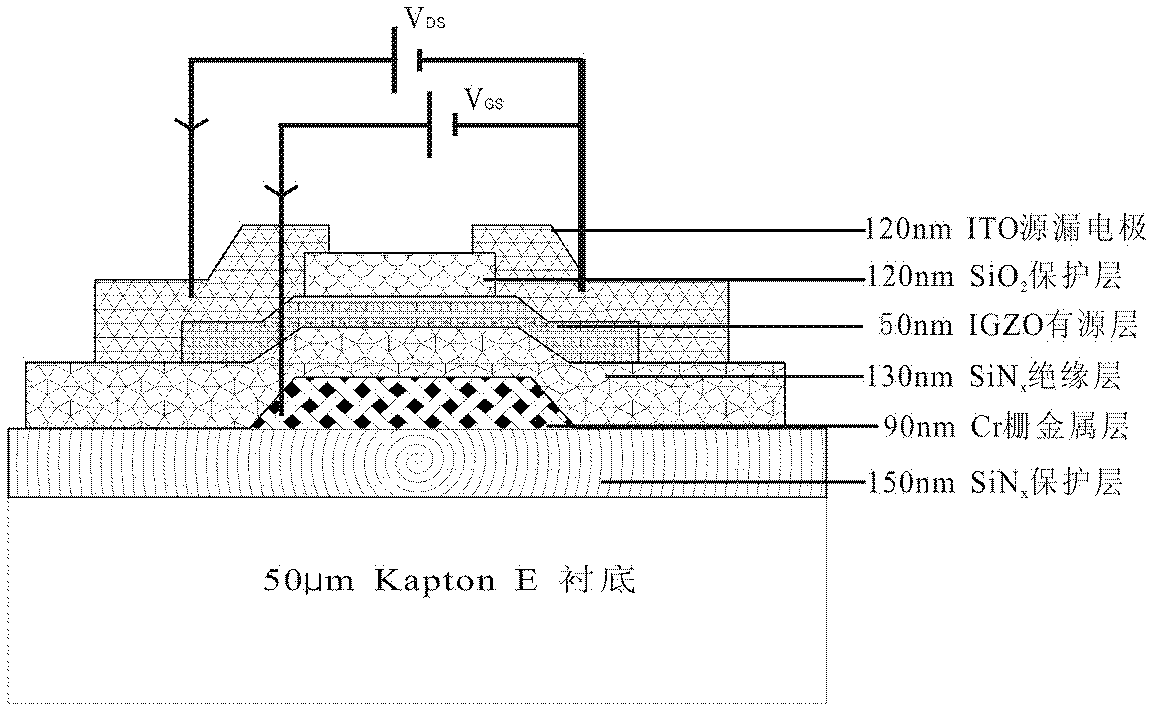

[0047] A flexible IGZO thin film transistor provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0048] Fabrication and Characterization of Thin Film Layer of Flexible IGZO-TFT Device Structure

[0049] The goal of this application is to find a suitable flexible substrate, explore the thin film materials and preparation technology of each layer of TFT, and realize the three-primary-color-driven microcapsule display unit by making and testing the electrical properties of IGZO-TFT device samples, analyzing and continuously improving the process parameters The required TFT device, the above work involves equipment including magnetron sputtering system, plasma enhanced chemical vapor deposition (PECVD) system and reactive ion etching (RIE) system, etc., which will be introduced in detail below.

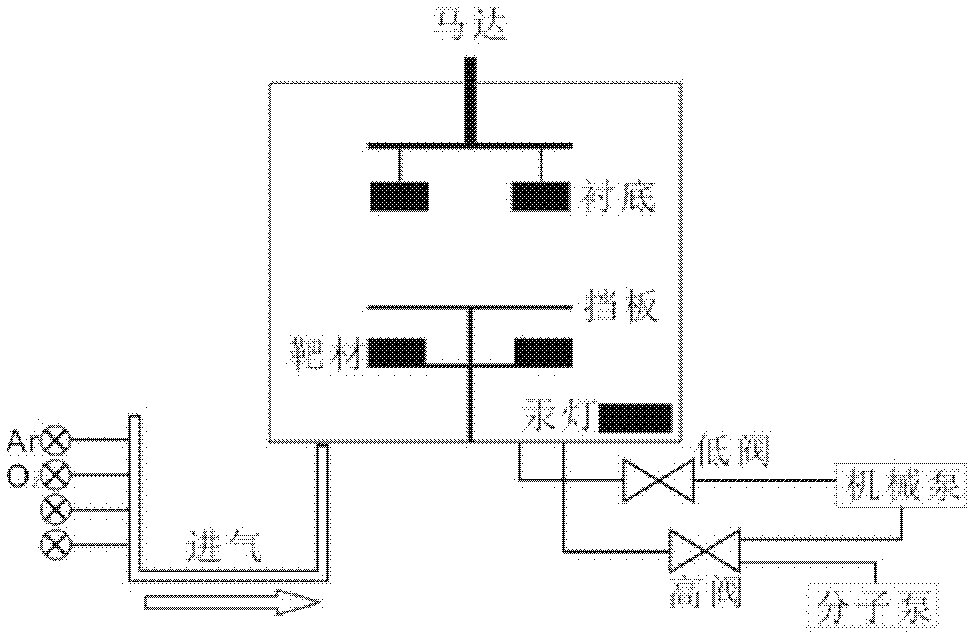

[0050] Magnetron sputtering system

[0051] In this work, the gate electrode, source-drain electrode and semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com