Novel processing tool for graphite carbon plate of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, which is used in fuel cell parts, fuel cells, sustainable manufacturing/processing, etc., can solve the problems of difficult production and processing of graphite carbon plates, low yield, etc. The effect of improving productivity and avoiding air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

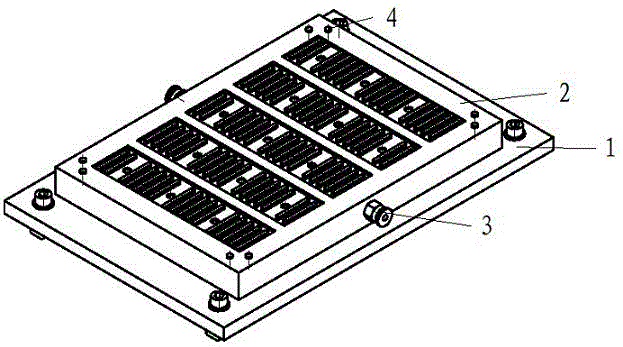

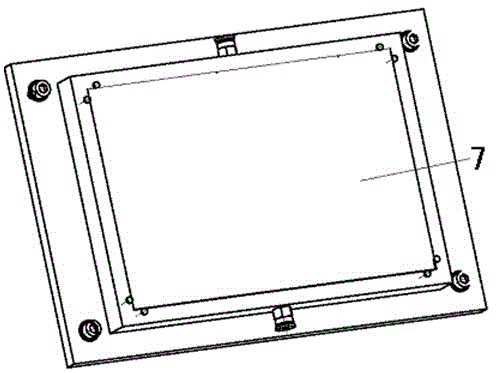

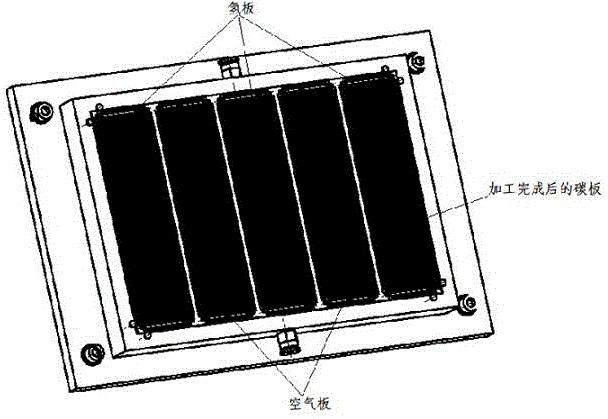

[0020] A tooling tool for processing a new type of graphite carbon plate for proton exchange membrane fuel cells. It includes a vacuum chuck bottom plate 1 and a vacuum chuck panel 2. The four corners of the vacuum chuck bottom plate 1 are provided with four special positioning pins 4 for positioning the vacuum chuck panel 2. The front side of the suction cup panel is provided with a runner groove I5, the reverse side is provided with a runner groove Ⅱ6, and two pneumatic connectors 3 are provided on both sides. One head of the pneumatic connector 3 communicates with the front runner groove I5-1 of the vacuum suction cup panel, and the other head It communicates with runner groove II6 on the reverse side. The function of the vacuum chuck bottom plate 1 is to connect and fix with the machine tool, while maintaining the level and flatness of the machining equipment to ensure the accuracy of the graphite carbon plate 7 processing; the function of the vacuum chuck plate 2 is to adso...

Embodiment 2

[0028] Proton exchange membrane fuel cell generator graphite carbon plate production and processing tooling is composed of vacuum suction plate 1, vacuum suction plate 2, 1 / 8" pneumatic connector 3, special positioning pin 4, etc. The size is 1124.8mm * 58 mm *3mm graphite carbon plate processing ( figure 1 ). First, fix the vacuum suction cup bottom plate around the processing table to ensure that the suction cup bottom plate is horizontal and vertical to the processing table. Place the carbon plate on the vacuum chuck panel, and the special positioning pin will determine the processing position of the carbon plate. The front of the vacuum suction cup panel is shown ( Figure 4 ) Runner slot The size of runner slot I5 is 186mm*61mm*3mm, the middle hole is ?4, and the height of the protruding slot platform is 3mm. The angle of the intersection of the runner grooves is 15°. In this way, the effective area of the carbon plate and the panel can be maximized, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com