Full-solid passive mode-locking picosecond laser

A passive mode-locking and laser technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of high cost, limited application range, easy damage to SESAM, etc., and achieve the effect of simple and compact structure and low repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

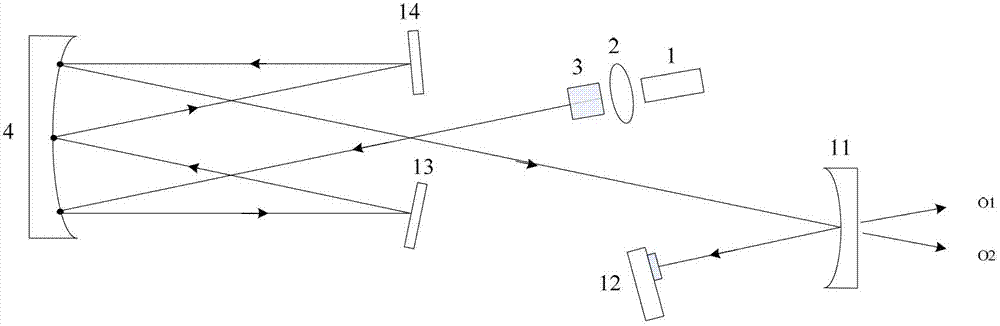

[0022] This embodiment provides an all-solid-state passive mode-locked picosecond laser, the structure of which is as follows figure 1 As shown, it includes: semiconductor pump source 1; coupling system 2; laser crystal 3; plano-concave mirror 4; first plane total reflection mirror 13; second plane total reflection mirror 14; output mirror 11;

[0023] Wherein the concave surface of said plano-concave mirror 4 is placed toward the reflective surface of the first plane total reflection mirror 13 and the second plane total reflection mirror 14, and the first plane total reflection mirror 13 and the second plane total reflection mirror 14 are relative to the plano-concave mirror The axis of 4 is symmetrically placed, and there is a small angle between the normal of the first plane total reflection mirror 13 and the second plane total reflection mirror 14 and the axis of the plano-concave mirror 4, and the pumping power emitted by the semiconductor pump source 1 The light is focus...

Embodiment 2

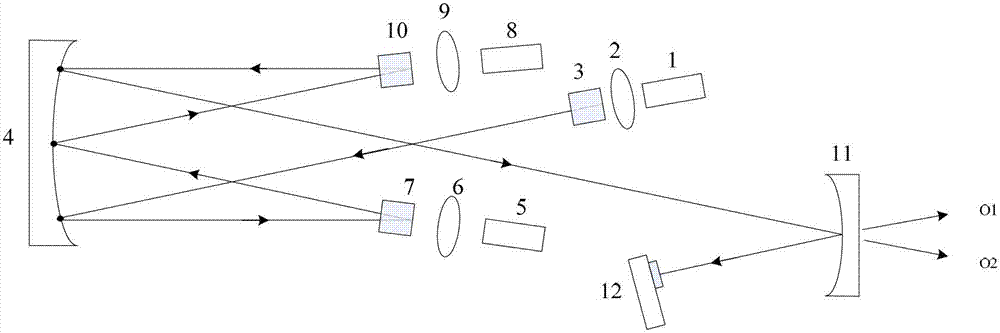

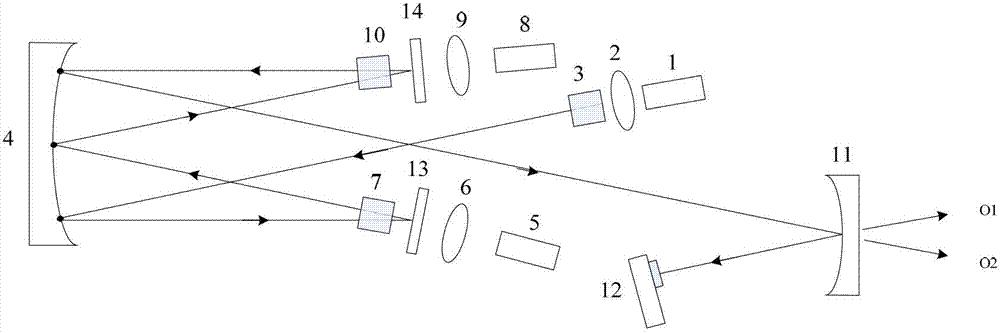

[0027] This embodiment provides an all-solid-state passive mode-locked picosecond laser, the structure of which is as follows figure 2 As shown, it includes: a first semiconductor pump source 1; a first coupling system 2; a first laser crystal 3, the first surface of which is coated with an antireflection film for pump light and a high reflection film for signal light, and the second surface is coated with Anti-reflection coating for pump light and signal light; plano-concave mirror 4; second semiconductor pump source 5; second coupling system 6; second laser crystal 7, the first surface is coated with anti-reflection for pump light and anti-signal Optical high reflection film, the second surface is coated with anti-reflection coating for pump light and signal light; the third semiconductor pump source 8; the third coupling system 9; the third laser crystal 10, the first surface is coated with anti-pump light Anti-reflection and high-reflection film for signal light, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com