Electronic stepless speed regulation system for hybrid electric vehicles

A hybrid electric vehicle, stepless speed regulation technology, applied in the field of automobile power, can solve problems such as gear noise, difficult heat dissipation, extra loss, etc., and achieve the effects of improving efficiency and reliability, simplifying structure, and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

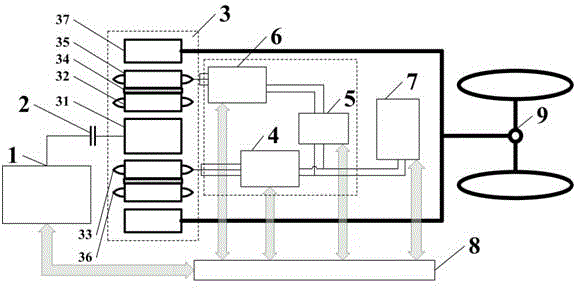

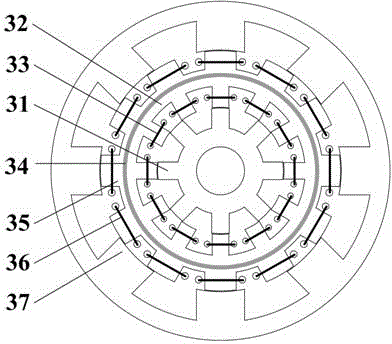

[0024] Such as figure 1 The electronic stepless speed regulation system for hybrid electric vehicles based on the composite switched reluctance motor of the present invention includes: engine 1, clutch 2, composite switched reluctance motor 3, electric power module (inner stator side power converter 4, DC -DC converter 5, outer stator side power converter 6), battery pack 7, control unit 8, wheel drive system 9, etc. The engine 1 is connected to the inner rotor 31 of the compound switched reluctance motor 3 through the clutch 2, and the inner stator winding 33 of the compound switched reluctance motor 3 passes through the inner stator side power converter 4, the DC-DC converter 5, the outer stator side The power converter 6 is connected to the outer stator winding 36 of the composite switched reluctance motor 3, the battery pack 7 is connected to the inner stator side power converter 4 and the DC-DC converter 5 respectively, and the outer rotor of the composite switched reluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com