Slide-transmission wire used in overhead crane

A technology for sliding transmission lines and cranes, which is applied in the field of sliding transmission lines for cranes, and can solve problems such as bending and deformation of sliding transmission line rails, breaking of current collector frames, and twisting of sliding transmission lines, so as to ensure normal operation and structure Simple, easy-to-handle and use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

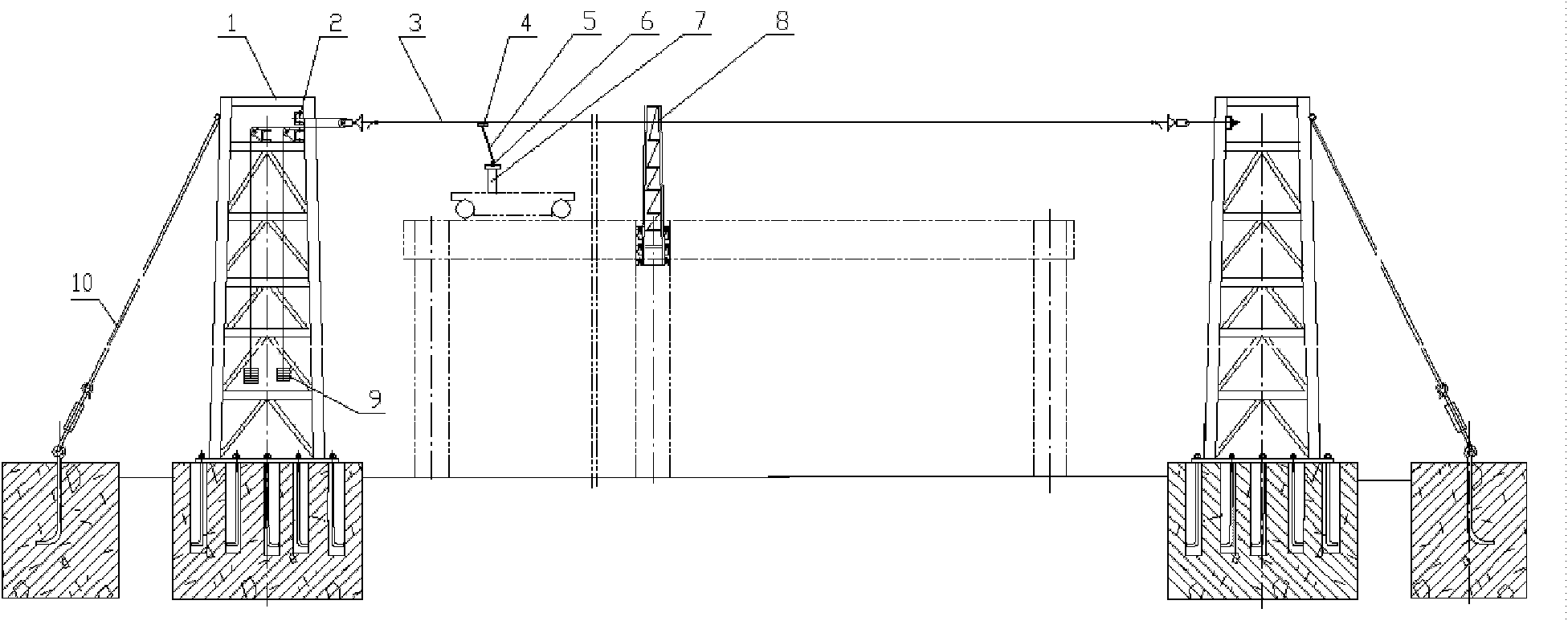

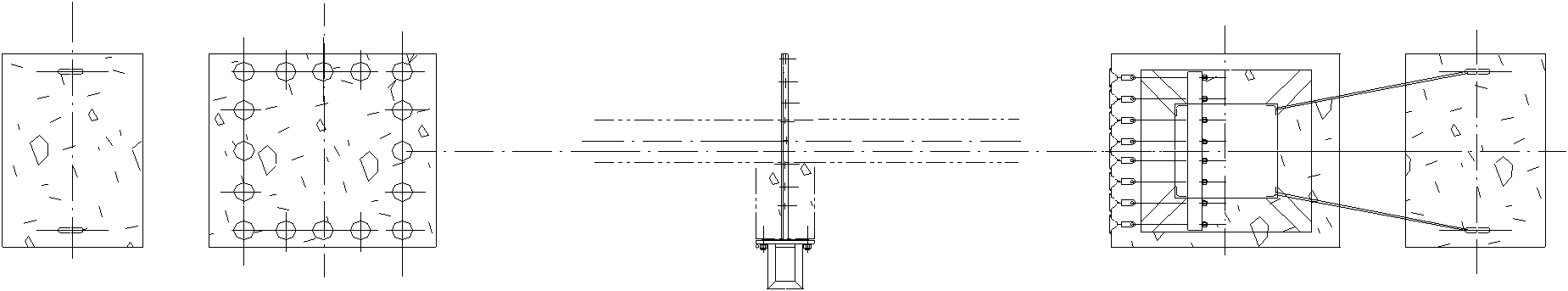

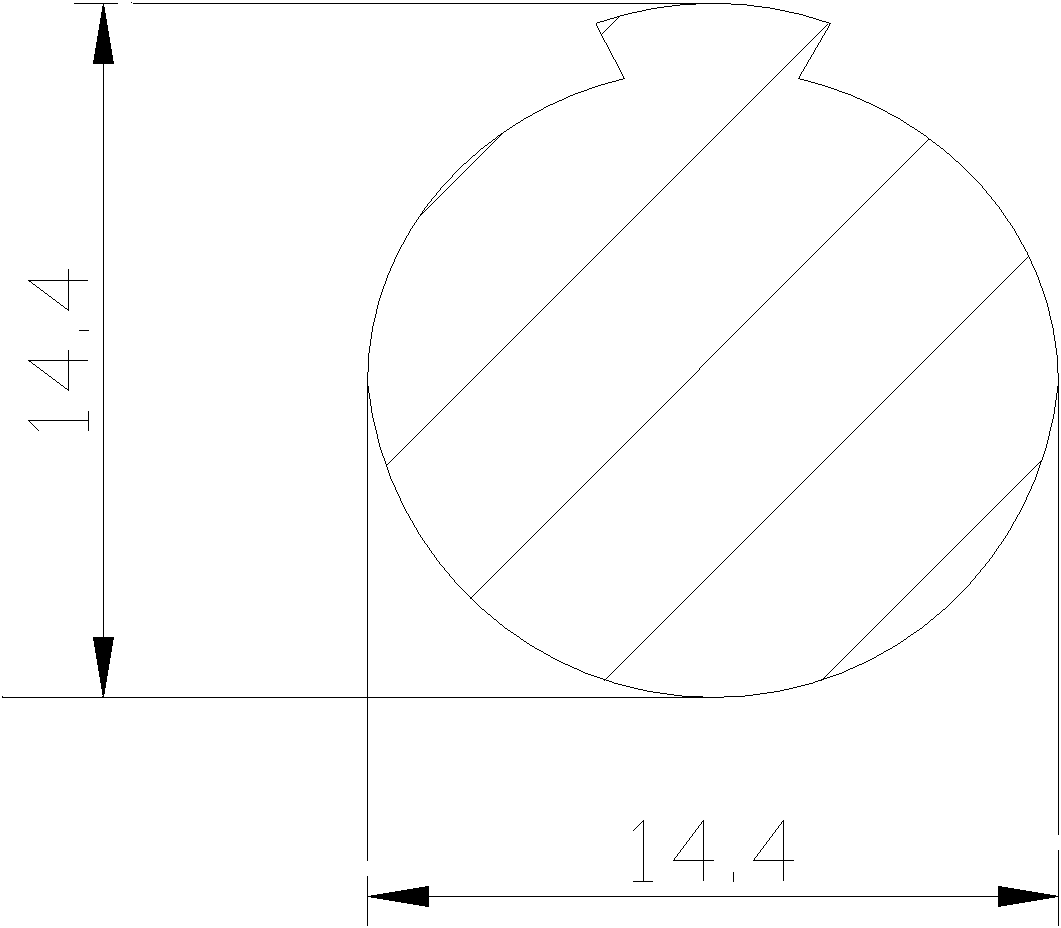

[0034] Such as figure 1 As shown, a kind of trolley transmission line for overhead crane mainly includes a truss type large iron tower 1 for placing a suspension wire porcelain vase, a suspension wire porcelain vase 2 for tensioning cables, and a CT series copper trolley wire 3 (its section is as shown in Fig. image 3 shown. ), the slider 4 that plays a conductive role, the collector frame 5 that plays the role of transmitting electricity, the universal joint that can adjust the position of the collector frame 5 , the fixed frame for power transmission of the crane 7, and the inverted L-shaped small iron tower that fixes the tram line 3 8, tighten the counterweight 9 of tram line 3, play the cable stay 10 of stable large iron tower.

[0035] The truss-type large iron towers 1 are fixed on the concrete foundation by anchor bolts, and the outsides of the two truss-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com