DC microresistivity measuring system

A measurement system and micro-resistance technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of amplifier range and temperature drift affecting measurement accuracy, etc., and achieve easy access to devices, mature circuits, and improved The effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

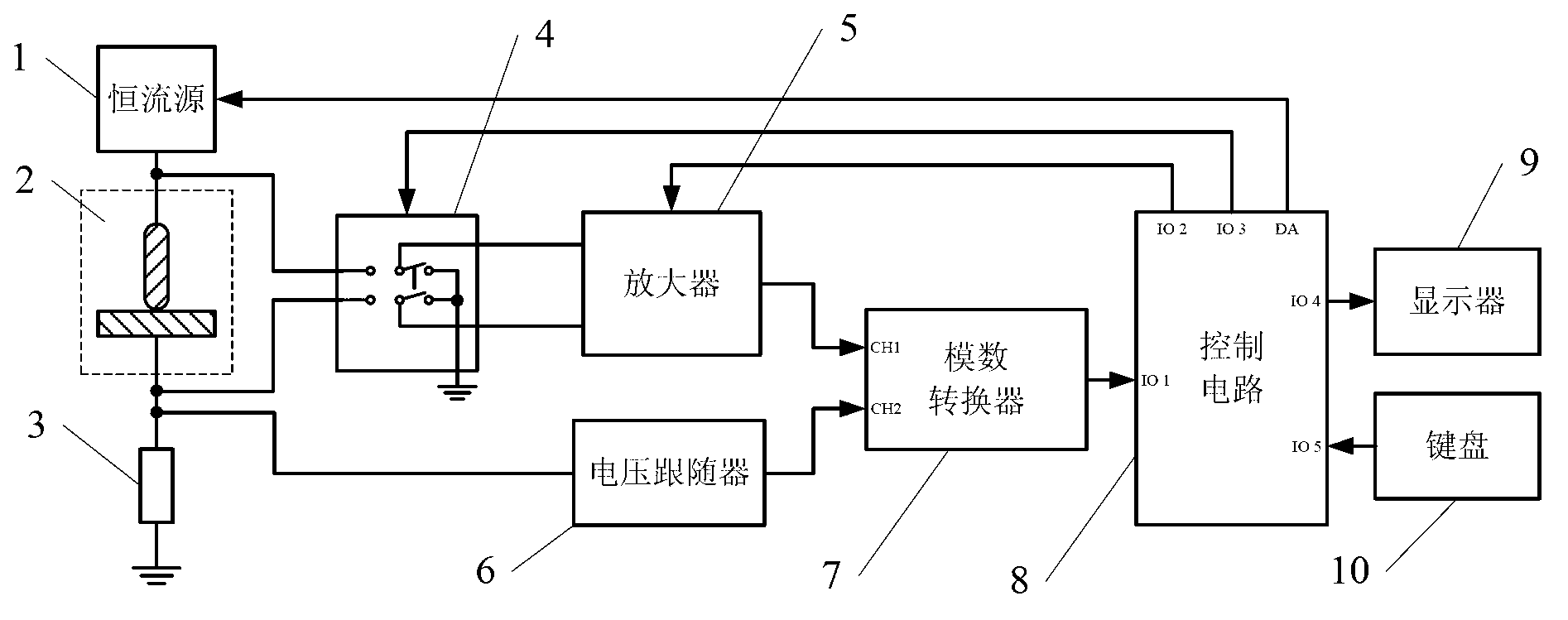

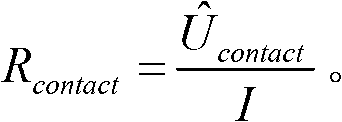

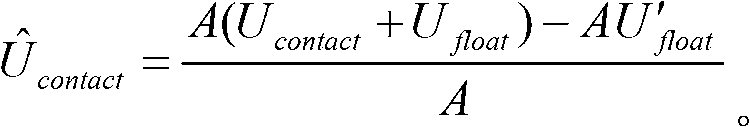

[0023] Embodiment 1: The DC micro-resistance measurement system described in this embodiment includes a constant current source 1, a standard current-sensing resistor 3, an amplifier 5, a voltage follower 6, an analog-to-digital converter 7 and a control circuit 8, and the constant current source 1 is used to provide excitation current to the component under test 2 and the standard current-sensing resistor 3 connected in series; the voltage signal of the standard current-sensing resistor 3 to ground is collected by the voltage follower 6 and then output to the analog-to-digital converter 7. The converter 7 outputs to the control circuit 8 after conversion; the voltage at both ends of the component under test 2 is collected and amplified by the amplifier and then output to the analog-to-digital converter 7, and then output to the control circuit 8 after being converted by the analog-to-digital converter 7;

[0024] A software module is embedded in the control circuit 8, and the ...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is a further limitation of the DC micro-resistance measurement system described in Embodiment 1. In this embodiment, the standard current-sensing resistor 3 is realized by a precision high-power wire-wound resistor.

[0032] Precision high-power wire-wound resistors have the advantage of stable resistance. Using this kind of resistor as a standard resistor to realize current detection can improve the measurement accuracy of current, and then improve the measurement accuracy of resistance value.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is a further limitation of the DC micro-resistance measurement system described in Embodiment 1 or Embodiment 2. In this embodiment, the amplifier 5 is realized by a differential input amplifier.

[0034] The amplifier in this embodiment adopts a differential input amplifier, which has the advantage of high measurement accuracy and can improve the accuracy of the voltage difference between the two ends of the measured component 4 , thereby ensuring the accuracy of the obtained resistance value of the measured component 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com