In-loop simulation test bed for hardware of transmission control unit of dry-type dual clutch transmission

An automatic transmission, electronic control unit technology, applied in the direction of instruments, simulators, general control systems, etc., can solve the problems of cumbersome configuration process, lack of dual-clutch modules, and difficulty in applying control strategies to real vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

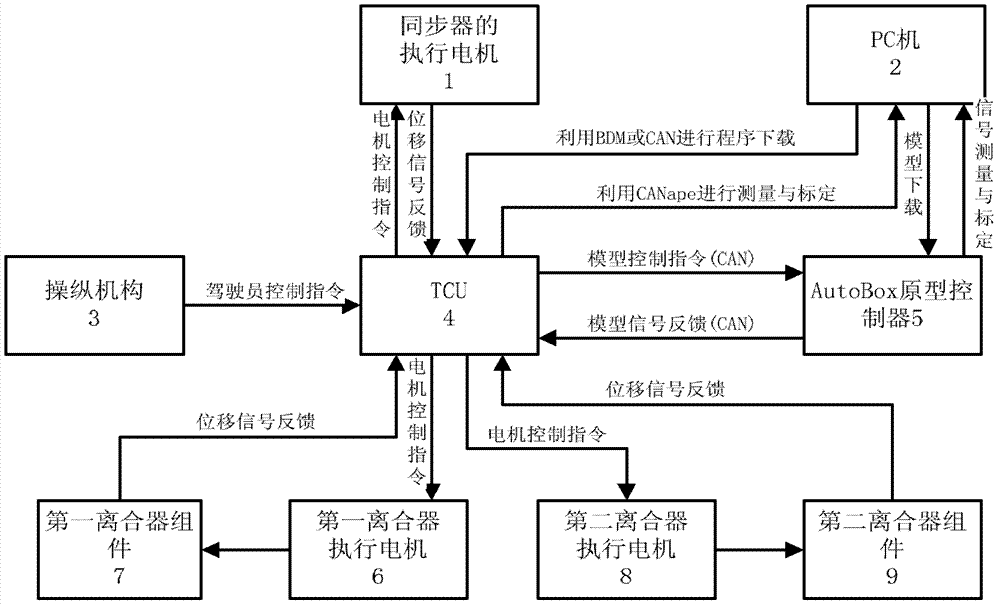

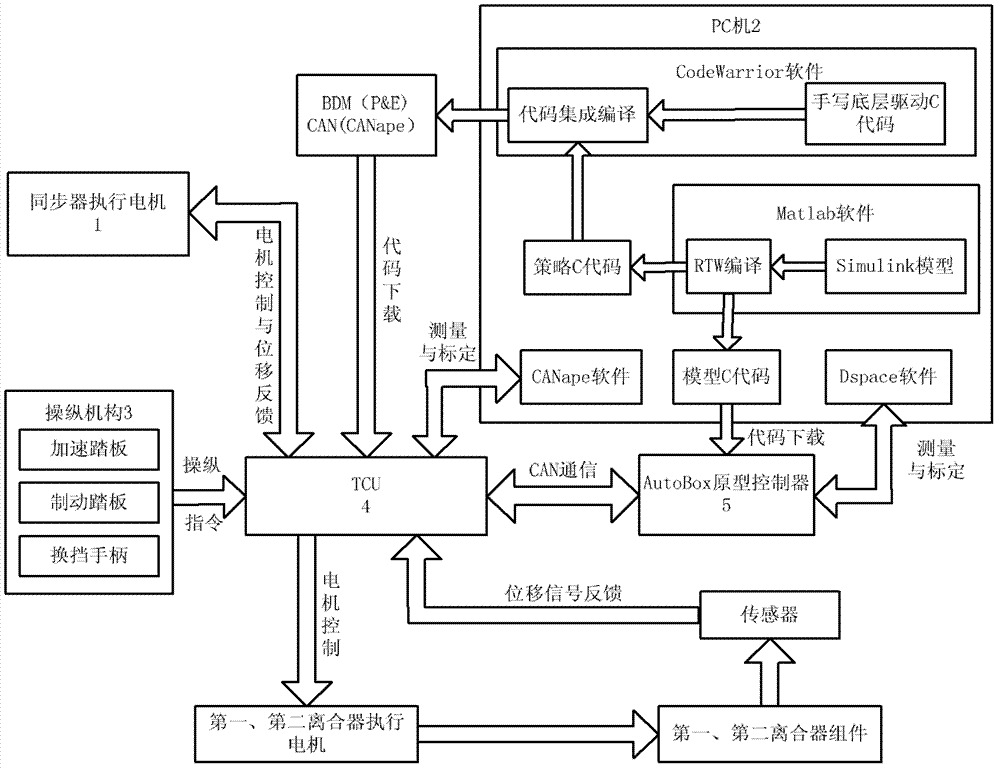

[0069] Such as figure 1 , figure 2 As shown, a hardware-in-the-loop simulation test bench for the electronic control unit of a dry-type dual-clutch automatic transmission, including a synchronizer actuator motor 1, a PC machine 2, an Autobox prototype controller 5, an electronic control unit TCU4, a clutch actuator motor, and a driving control mechanism 3 and clutch assembly, described electronic control unit TCU4 is connected with synchronizer executive motor 1, PC machine 2, Autobox prototype controller 5, clutch executive motor, driving control mechanism 3, clutch assembly respectively, described PC machine 2 and Autobox prototype controller 5 is connected, and described clutch executive motor is connected with clutch assembly;

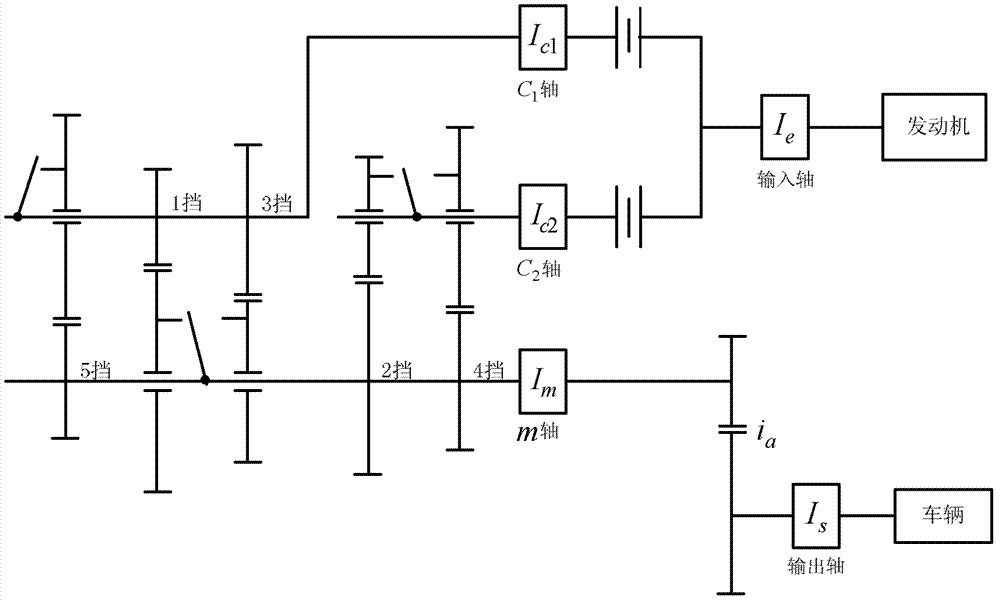

[0070] The PC 2 establishes the dynamic simulation model of the dual-clutch automatic transmission under different working conditions. The model is converted into C code format by RTW and downloaded to the Autobox prototype controller 5; the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com