Double-heterostructure GaN-based high-electron mobility transistor structure and preparation method

A high electron mobility, double heterostructure technology, applied in semiconductor/solid state device manufacturing, circuits, electrical components, etc., can solve problems such as reducing electron mobility and controversy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

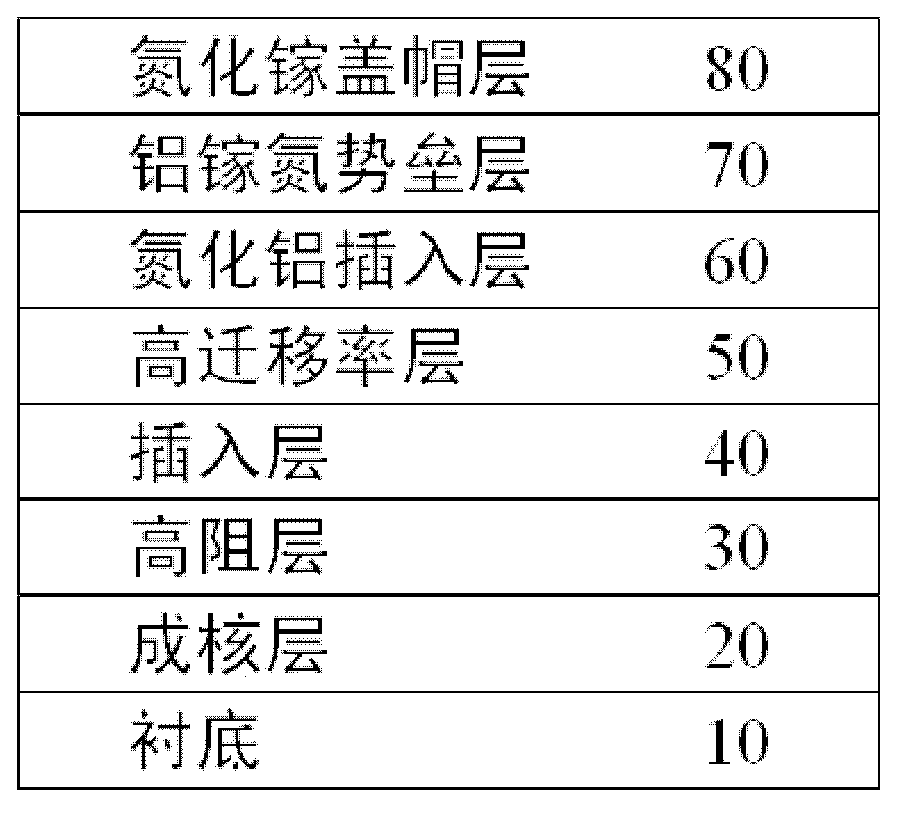

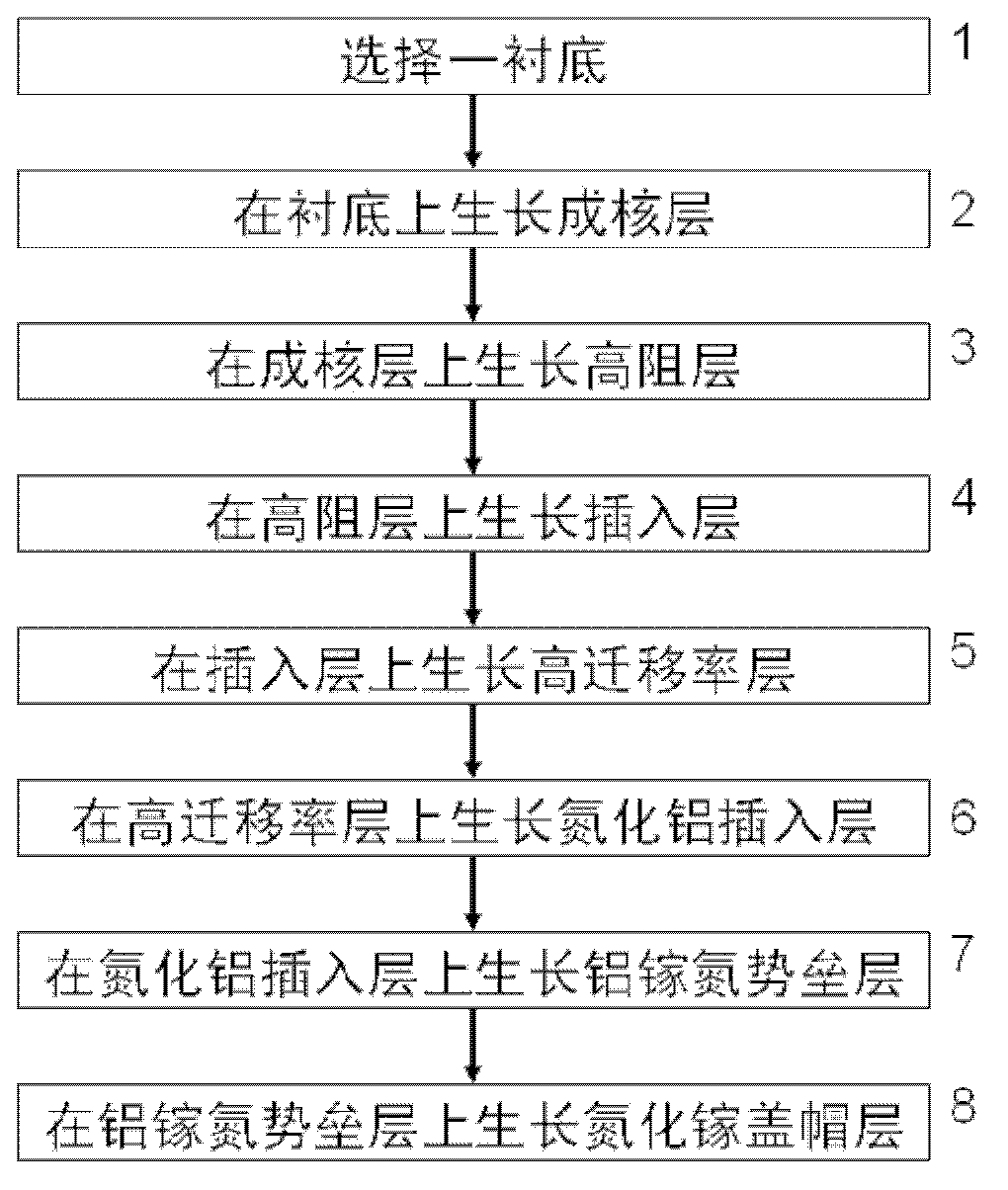

[0027] see figure 1 As shown, a double heterostructure GaN-based high electron mobility transistor structure of the present invention includes:

[0028] a substrate 10;

[0029] A nucleation layer 20, the nucleation layer 20 is fabricated on the substrate 10, the nucleation layer 20 is gallium nitride or aluminum nitride or aluminum gallium nitride, with a thickness of 0.01-0.50 μm.

[0030] An unintentionally doped high-resistance layer 30, the unintentionally doped high-resistance layer 30 is fabricated on the nucleation layer 20, and the material of the unintentionally doped high-resistance layer 30 is Al y Ga 1-y N, where 06 Ω.cm. The high-resistance layer 30 has four functions, one is to reduce the lattice mismatch between the substrate and the epitaxial layer as a buffer layer, and improve the crystal quality of the epitaxial layer; the other is to reduce device leakage as a high-resistance layer; It is used as the back barrier layer to raise the barrier height of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com