Method for producing 1,5-pentanediamine

A manufacturing method and a technology for pentamethylenediamine, which are applied in the directions of biochemical equipment and methods, carbon-carbon lyases, enzymes, etc., can solve the problem that the fermentation yield of 1,5-pentamethylenediamine is not improved, the economic problems, and the generation of by-products. Lysine etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

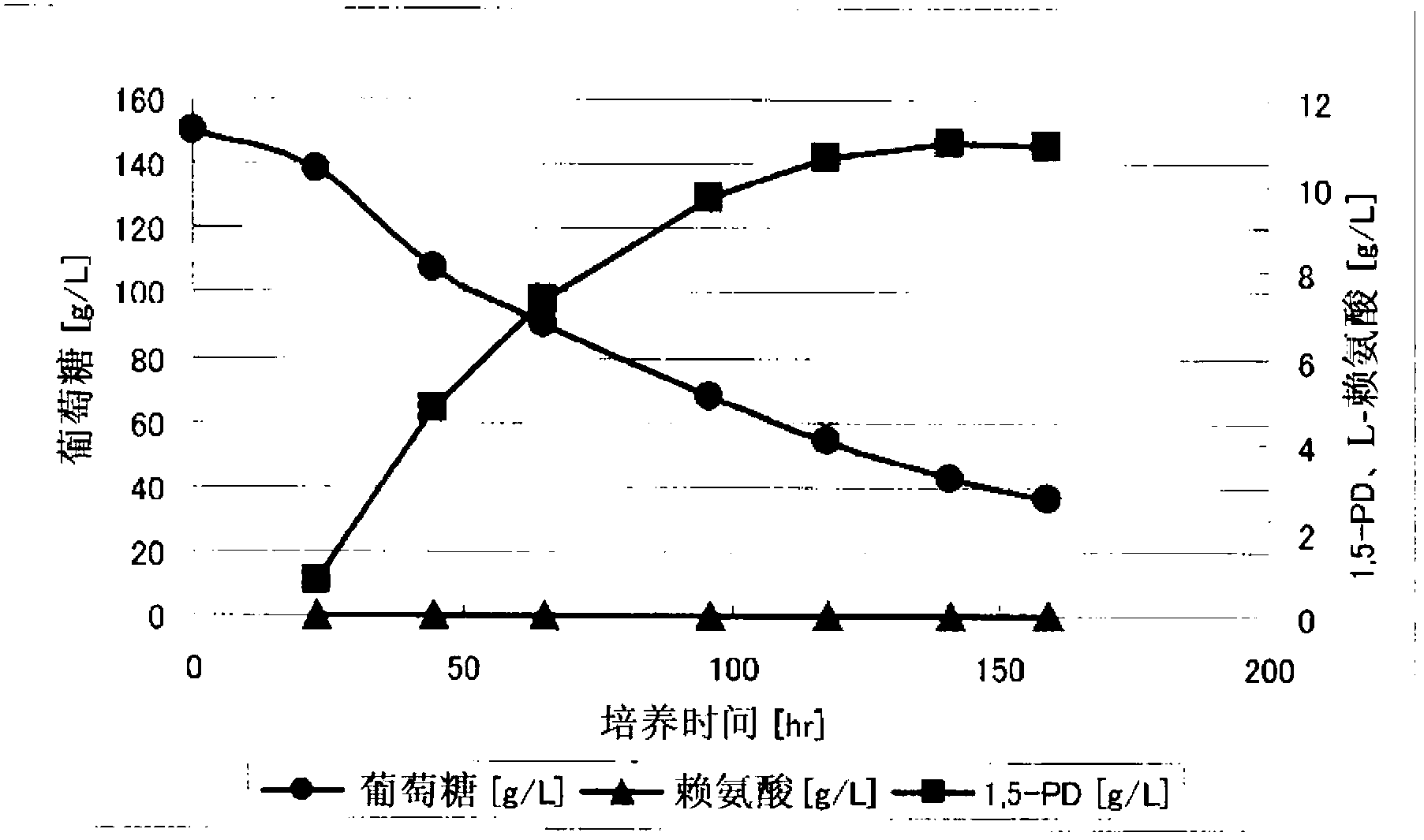

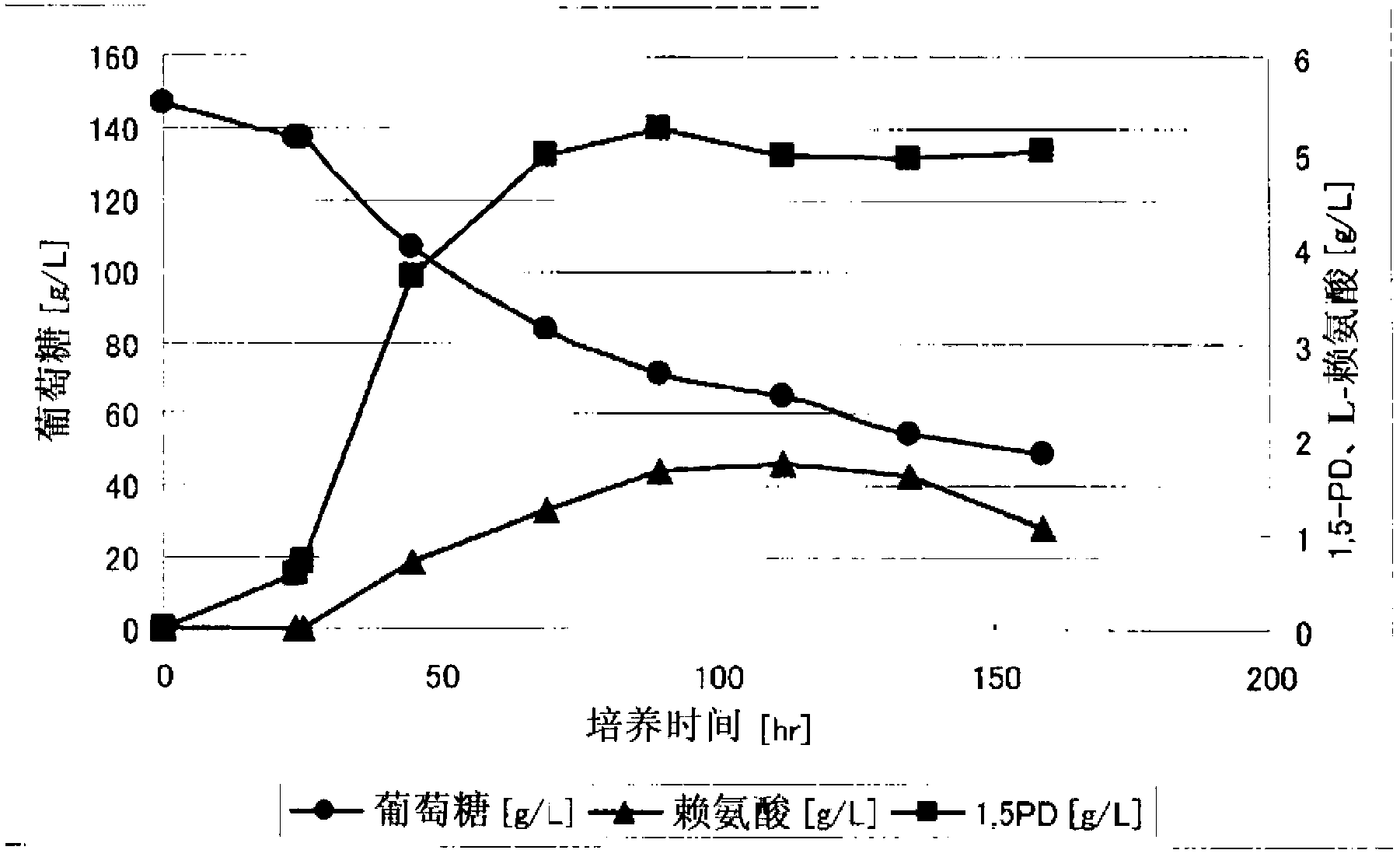

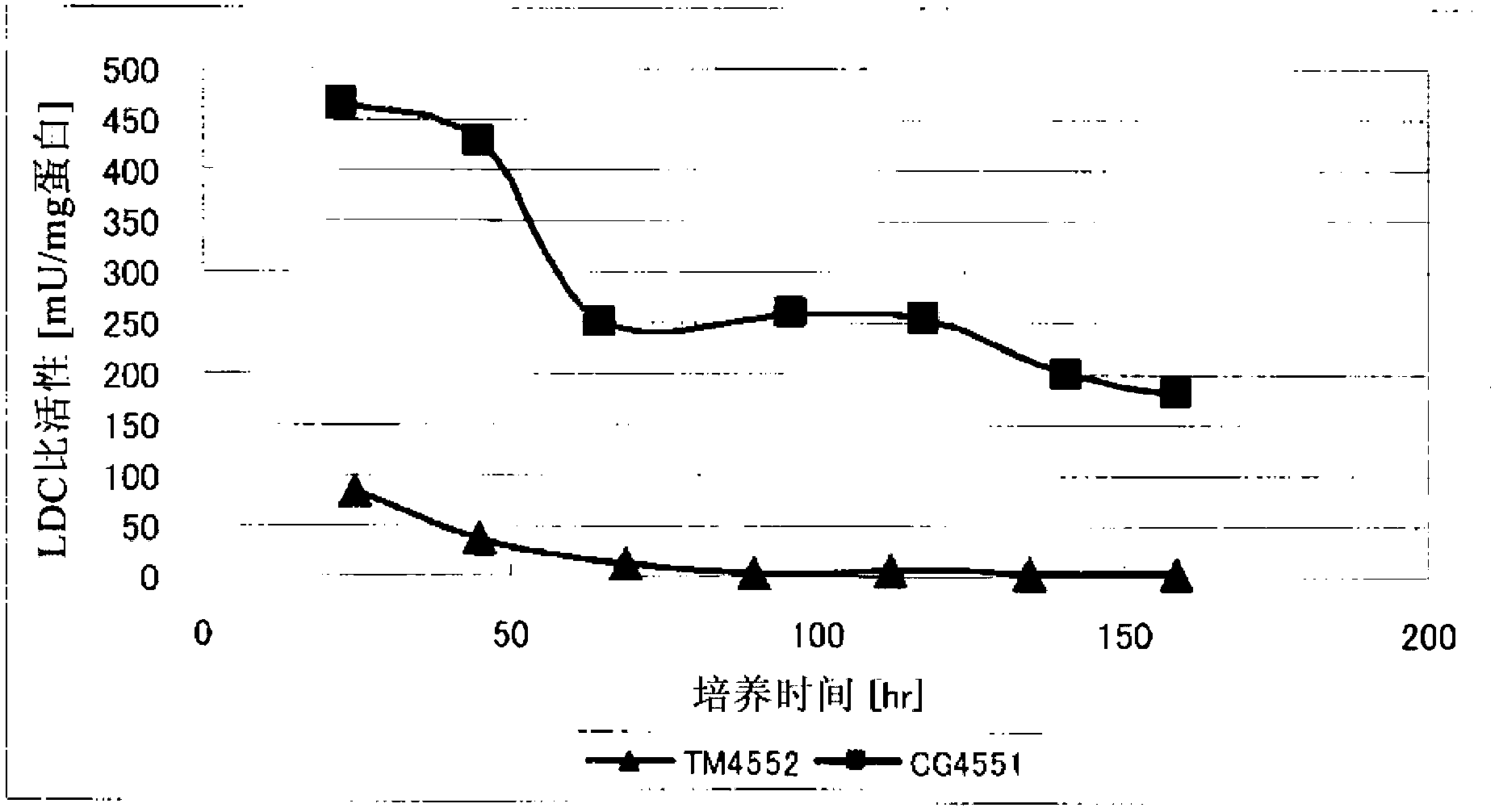

Embodiment 1、 comparative example 1

[0095] (1) Production of Corynebacterium glutamicum capable of fermenting and producing L-lysine

[0096] In order to produce Corynebacterium glutamicum capable of synthesizing L-lysine, a precursor of 1,5-pentanediamine, L-lysine-fermenting bacteria were created by introducing effective mutations into aspartokinase (AK) . Corynebacterium glutamicum AK-1 strain (hereinafter referred to as AK-1 strain) was prepared referring to the method described in Apppl. Microbiol. Biotechnol., (2002), 58, p.217-223. That is, this operation is specifically performed as follows.

[0097] Genomic DNA solution prepared according to conventional methods from Corynebacterium glutamicum ATCC13032 strain was used as an amplification template, and the oligonucleotide designed with reference to the base sequence of the AK gene (accession number: BA000036) registered in the database (GenBank) Nucleotides (sequence number: 4, 5) were used as a primer set for PCR, and the resulting product was electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com