A kind of rectifying method that contains iodohydriodic acid feed liquid

A technology of hydriodic acid and feed liquid, applied in the field of chemical engineering, can solve problems such as rectification of hydriodic acid that is difficult to contain iodine, and achieve the effect of preventing the failure of rectification operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

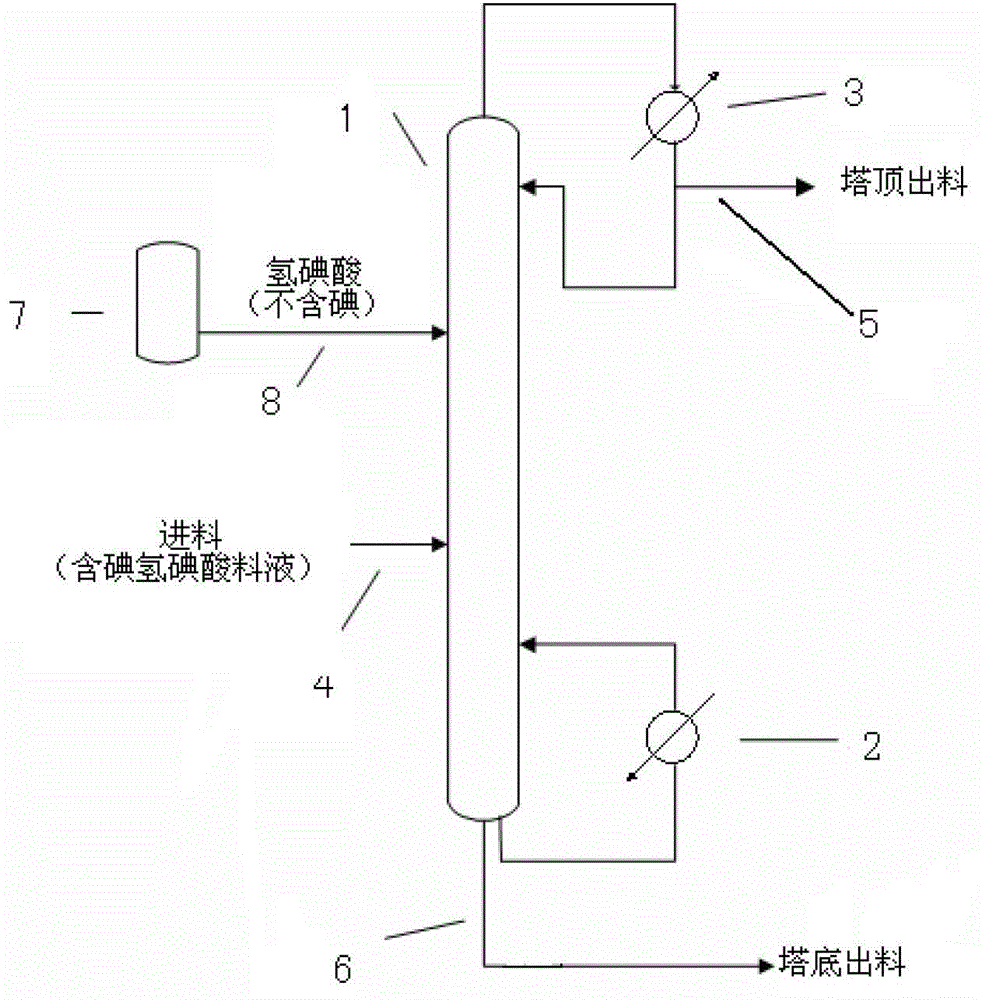

[0031] Such as figure 1 As shown, in this embodiment, the inner diameter of the packed tower is 5cm, the inner packing is a glass spring packing of Ф3mm*20mm, the height of the packing layer is 1m, and the feeding port of the feed liquid containing iodohydriodic acid is 0.8m away from the top of the tower. The inlet of the injection pipeline system 8 on the tower for drip irrigation of hydroiodic acid (ie, the aqueous solution of HI) is located at the top of the tower. The iodine-containing hydroiodic acid feed solution to be rectified consists of HI:H 2 O:I 2 =1:7.5:1.5, the concentration of the hydriodic acid solution in the hydriodic acid storage tank 7 is [HI]=6.0mol / L.

[0032] Before the rectification treatment of the above-mentioned iodine-containing hydriodic acid feed liquid, first open the hydriodic acid drip irrigation device, and drip hydriodic acid with a concentration of 6.0mol / L in the tower at a rate of 10ml / min for 5min, so that the hydriodic acid in the tow...

Embodiment 2

[0034] Such as figure 1As shown, in this embodiment, the inner diameter of the packed tower is 10cm, the inner packing is glass spring packing of Ф3mm*30mm, the height of the packing layer is 1.5m, and the feeding port of the feed liquid containing iodohydriodic acid is 1m away from the top of the tower. The inlet of the injection pipeline system 8 on the tower for drip irrigation of hydroiodic acid (ie the aqueous solution of HI) is 0.5m away from the top of the tower. The iodine-containing hydroiodic acid feed solution to be rectified consists of HI:H 2 O:I 2 =1:10:1.5, the concentration of the hydriodic acid solution in the hydriodic acid storage tank 7 is [HI]=3.0mol / L.

[0035] Before the rectification treatment of the above-mentioned iodine-containing hydriodic acid feed liquid, first open the hydriodic acid drip irrigation device, and drip hydriodic acid with a concentration of 3.0mol / L into the tower at a rate of 20ml / min. After 5min, keep 10ml The instillation rate...

Embodiment 3

[0037] Such as figure 1 As shown, in this embodiment, the inner diameter of the packed tower is 15cm, the inner packing is glass spring packing of Ф3mm*30mm, the height of the packing layer is 2m, and the feeding port of the feed liquid containing iodohydriodic acid is 1m away from the top of the tower, toward the packing The inlet of the tower drip irrigation hydroiodic acid (ie the aqueous solution of HI) 8 on the tower is 0.5m away from the top of the tower. The iodine-containing hydroiodic acid feed solution to be rectified consists of HI:H 2 O:I 2 =1:4:1.5, the concentration of the hydriodic acid solution in the hydriodic acid storage tank 7 is [HI]=0.5mol / L.

[0038] Before the rectification treatment of the above-mentioned iodine-containing hydroiodic acid feed liquid, first open the hydroiodic acid drip irrigation device, and drip the hydroiodic acid with a concentration of 0.5mol / L into the tower at a rate of 30ml / min, and after continuing for 5min, keep 10ml The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com