Pouring basket with molten steel purity stably improved under low argon consumption and metallurgical method thereof

A tundish and purity technology, applied in metal processing equipment, casting melt containers, manufacturing tools, etc., can solve the problems of increasing the total amount of inclusions, affecting the production cost, and being expensive, so as to improve the inclusion removal rate and increase the Purity, good metallurgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

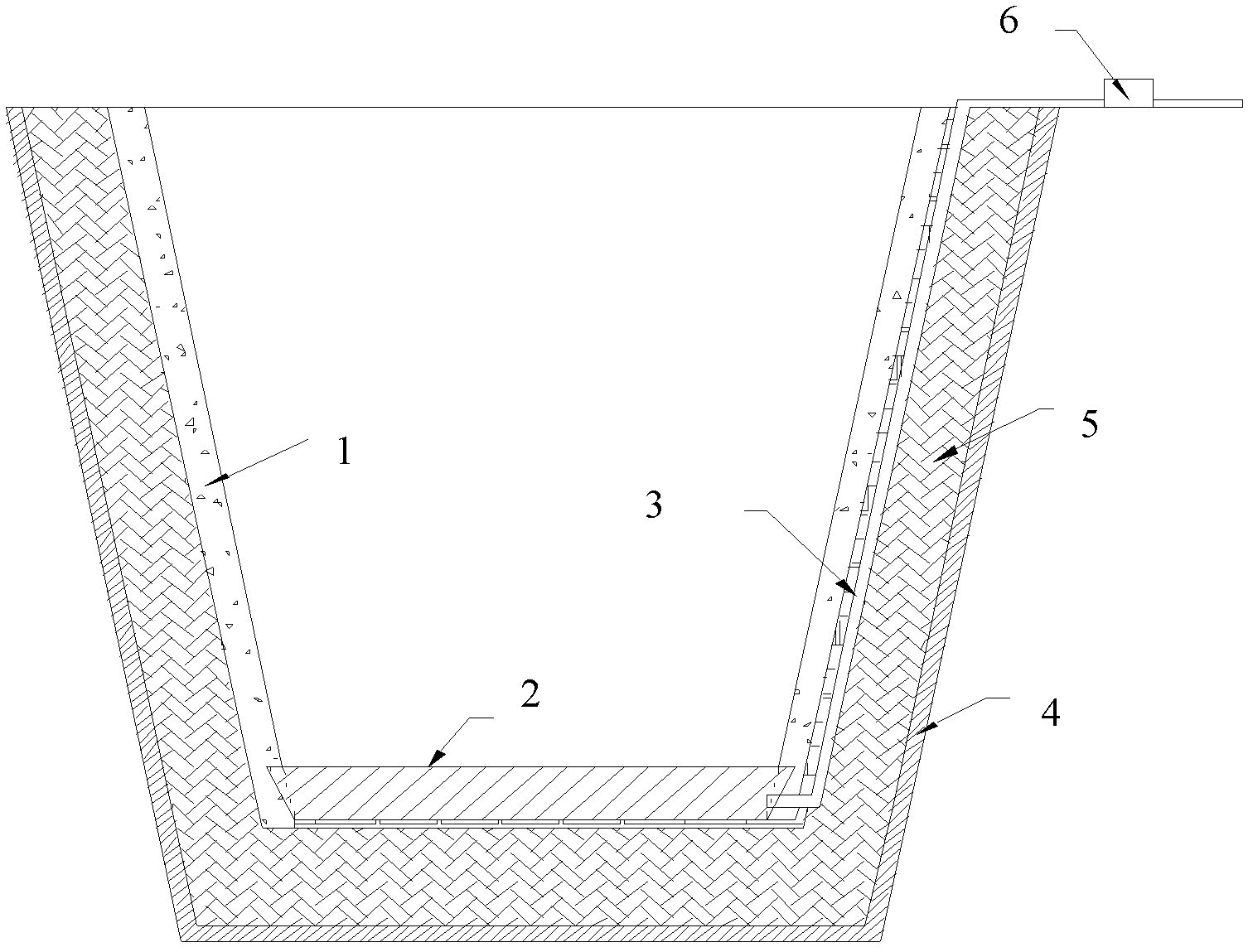

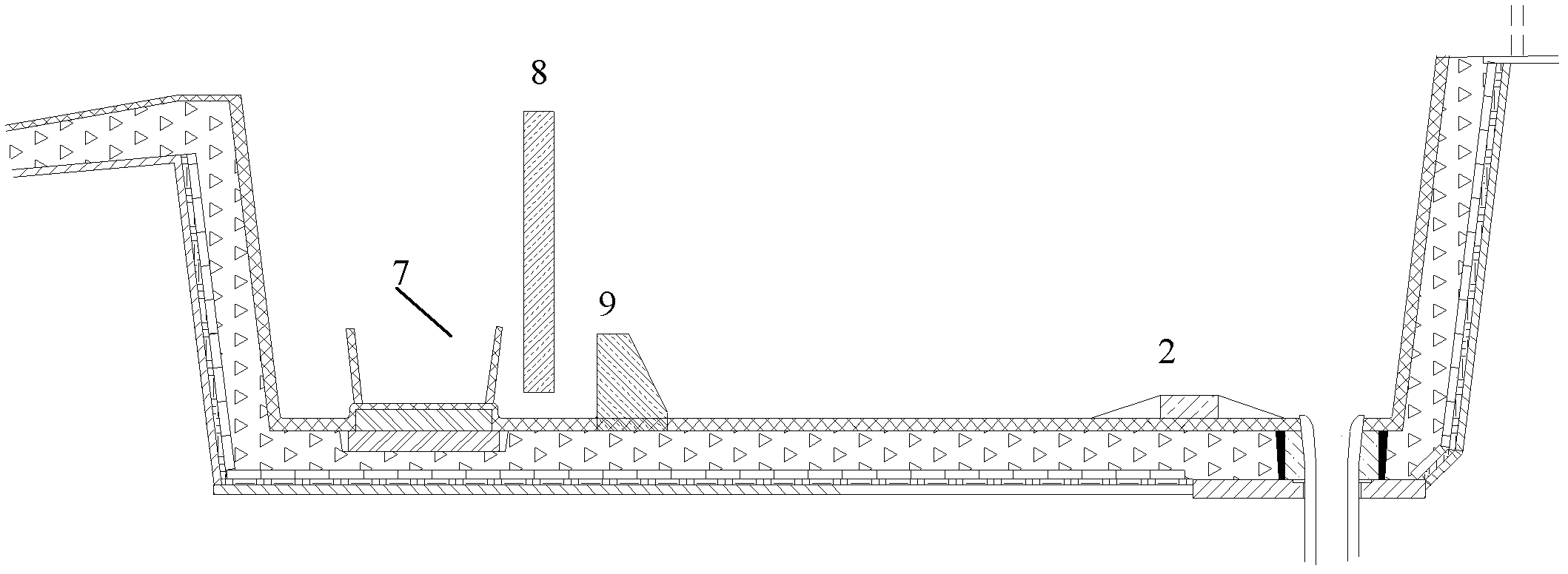

[0032] The production of stainless steel grade A requires argon gas treatment in the tundish, and the following operations shall be carried out after informing the production preparation operation area:

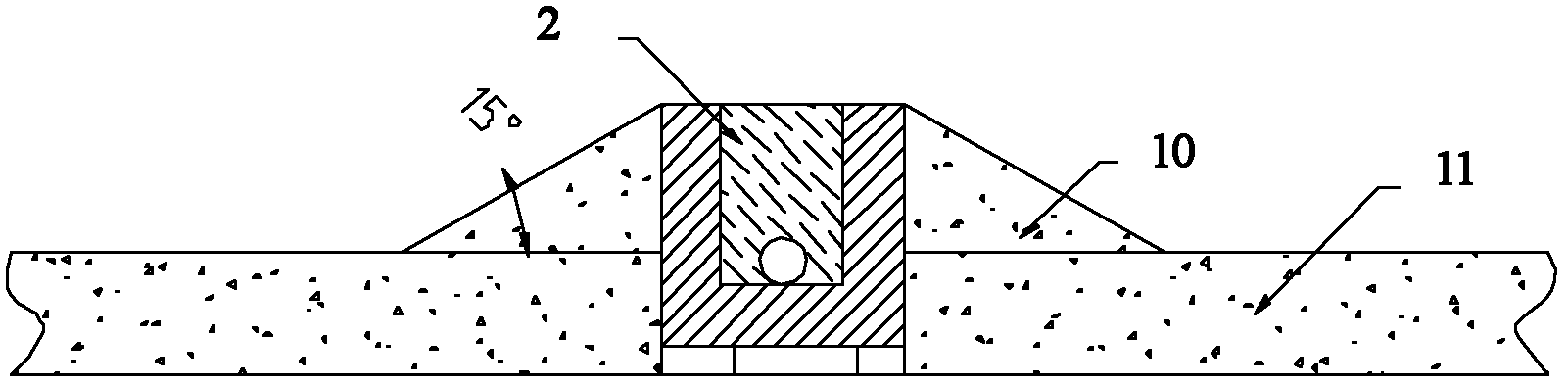

[0033] A magnesia retaining wall 8 is built in the tundish, the position is 300 mm behind the impact point of the molten steel, and the inner cavity of the tundish is divided into the impact area and the pouring area; a turbulence controller 7 is built at the origin of the impact of the molten steel in the impact area; Build a short dam 9 at 550mm behind the impact point of molten steel; build an air curtain brick 2 at a position 2100mm from the impact point in the pouring area.

[0034] The air curtain bricks are placed along the bottom of the bag, and the direction of the molten steel flow is 90°. After the placement is completed, the magnesia paint is manually covered on both sides of the air curtain bricks, and the magnesia paint is required to cover the entire air curtain...

Embodiment 2

[0040] The production of stainless steel grade A requires argon gas treatment in the tundish, and the following operations shall be carried out after informing the production preparation operation area:

[0041] A magnesia retaining wall 8 is built in the tundish, the position is 275 mm behind the impact point of the molten steel, and the inner cavity of the tundish is divided into the impact area and the pouring area; a turbulence controller 7 is built at the origin of the impact of the molten steel in the impact area; A short dam 9 is built 500mm behind the impact point of molten steel; an air curtain brick 2 is built at a position 2000mm from the impact point in the pouring area.

[0042] The air curtain bricks are placed along the bottom of the bag, and the direction of the molten steel flow is 90°. After the placement is completed, the magnesia paint is manually covered on both sides of the air curtain bricks, and the magnesia paint is required to cover the entire air curt...

Embodiment 3

[0048] The production of stainless steel grade A requires argon gas treatment in the tundish, and the following operations shall be carried out after informing the production preparation operation area:

[0049] A magnesia retaining wall 8 is built in the tundish, the position is 335 mm behind the impact point of the molten steel, and the inner cavity of the tundish is divided into the impact area and the pouring area; a turbulence controller 7 is built at the origin of the impact of the molten steel in the impact area; A short dam 9 is built at 530 mm behind the impact point of molten steel; an air curtain brick 2 is built at 1980 mm from the impact point in the pouring area.

[0050] The air curtain bricks are placed along the bottom of the bag, and the direction of the molten steel flow is 90°. After the placement is completed, the magnesia paint is manually covered on both sides of the air curtain bricks, and the magnesia paint is required to cover the entire air curtain br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com