Plant fiber homogeneous material and its preparation method

A plant fiber and homogeneous material technology, which is applied in the field of building thermal insulation materials, can solve the problems of flammable bacteria and other problems of plant fibers, and achieve the effects of good insulation, good waterproof performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

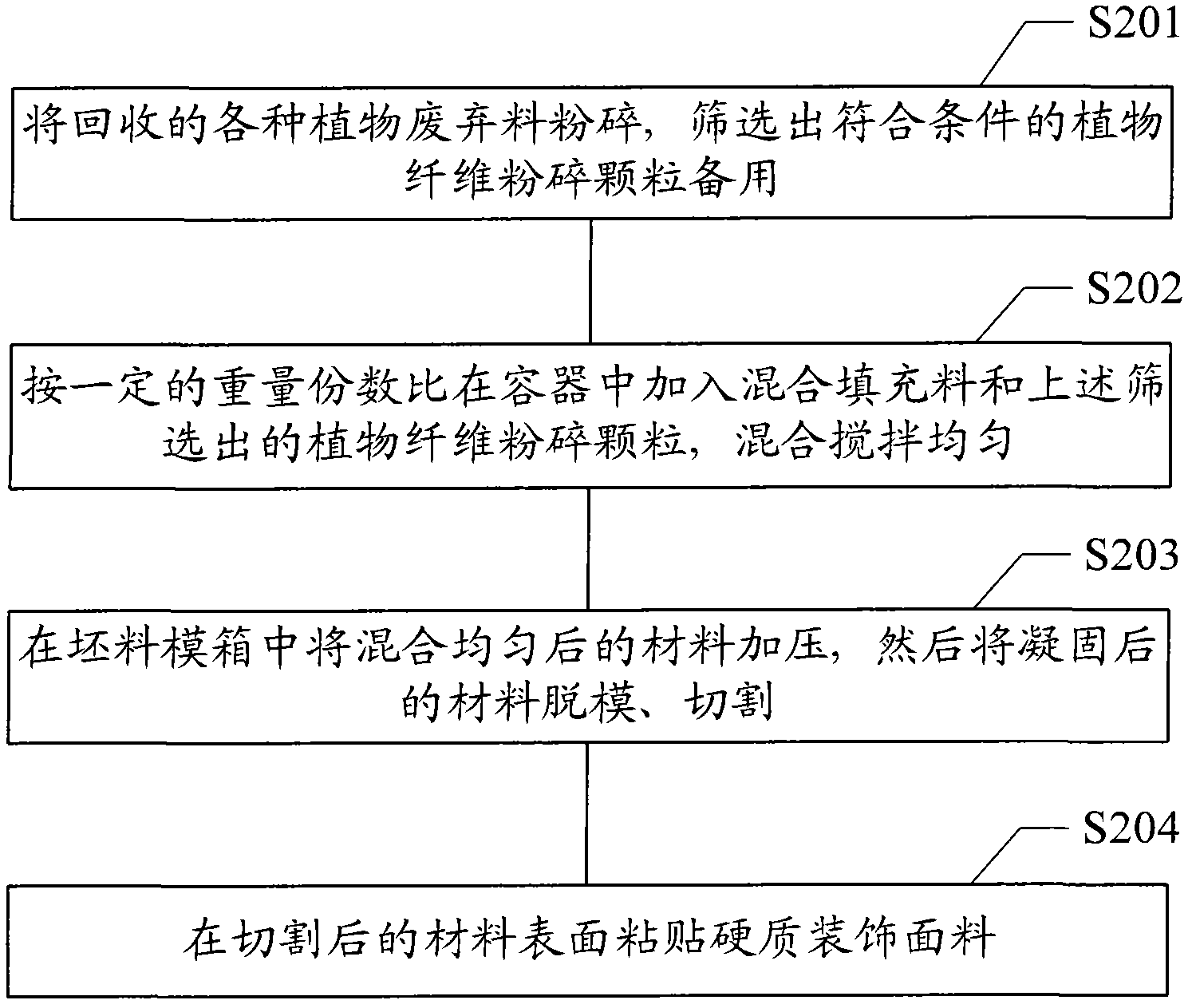

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

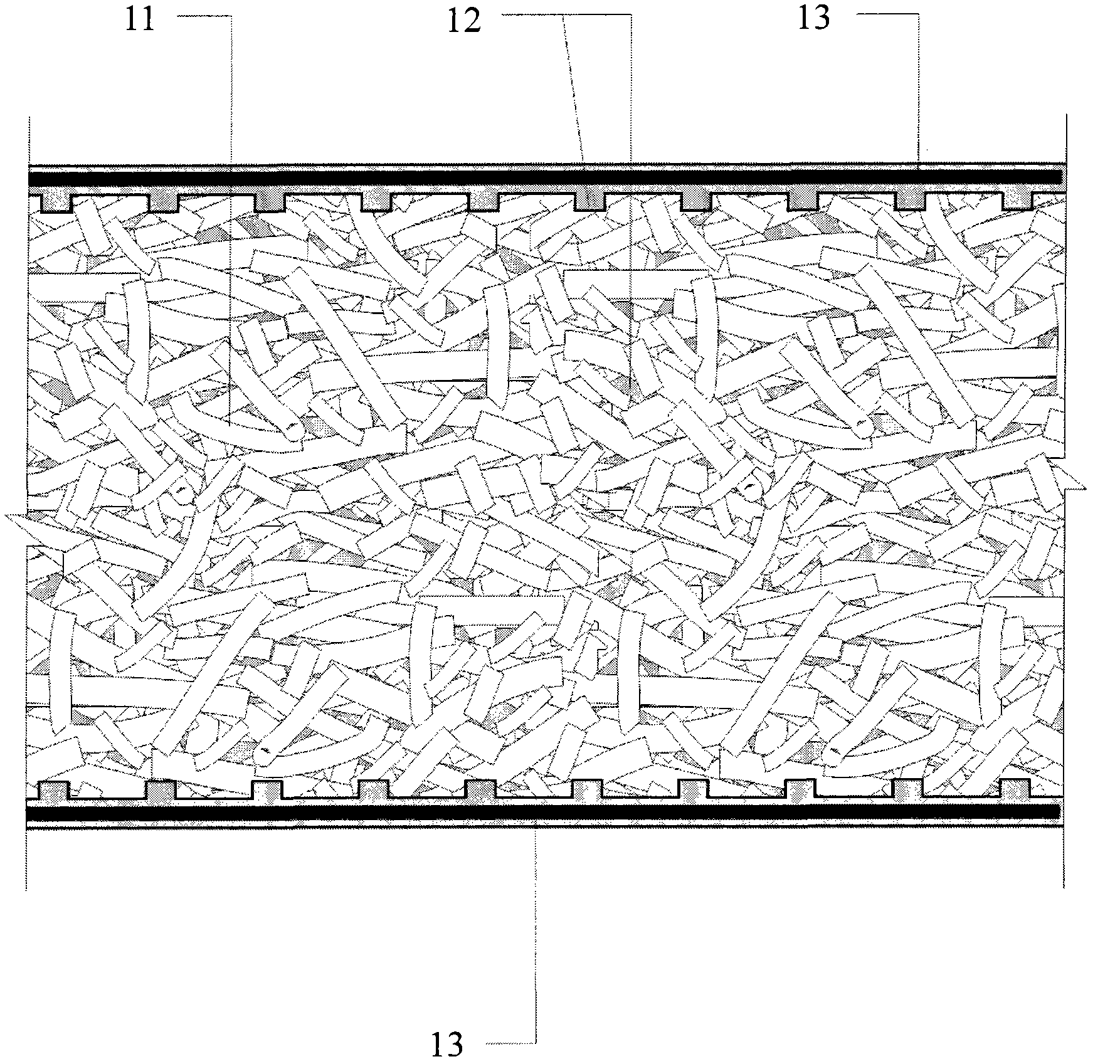

[0018] refer to figure 1 , shows a schematic structural view of an embodiment of the plant fiber homogeneous material of the present invention, including plant fiber pulverized particles 11, mixed filler 12 and hard decorative fabric 13, wherein:

[0019] The proportion relationship between the crushed plant fiber particles 11 and the mixed filler 12 is: 100-600 kg of crushed plant fiber particles / per ton of mixed filler;

[0020] The mixed filler 12 is used to wrap and solidify the pulverized plant fiber particles 11, and its composition and its parts by weight are as follows: 100 parts of rapid hardening cement, 1 to 25 parts of water reducing agent, 1 to 25 parts of expansion agent, 1 to 25 parts Curing agent, 1-25 parts of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com