Black fungus culture base and preparation method thereof

A cultivation base and technology of black fungus, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of susceptibility to bacterial infection and low yield of black fungus, improve disease resistance and resistance to bacterial infection, and ensure Healthy growth, easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Grind the peanut shells into powder with a pulverizer, weigh 30kg of powdered peanut shells, 18kg of cottonseed skins, 1kg of brown sugar, and 1kg of gypsum powder, mix well, then add 50kg of water, mix well, and put in In high temperature resistant polyethylene plastic bags, each bag is filled with 2.5kg of material; the bag is sterilized by steam at 100 degrees Celsius for 20 hours at normal pressure; after the bag material is cooled to normal temperature, the black fungus cultivation base is prepared.

[0026] Experimental data

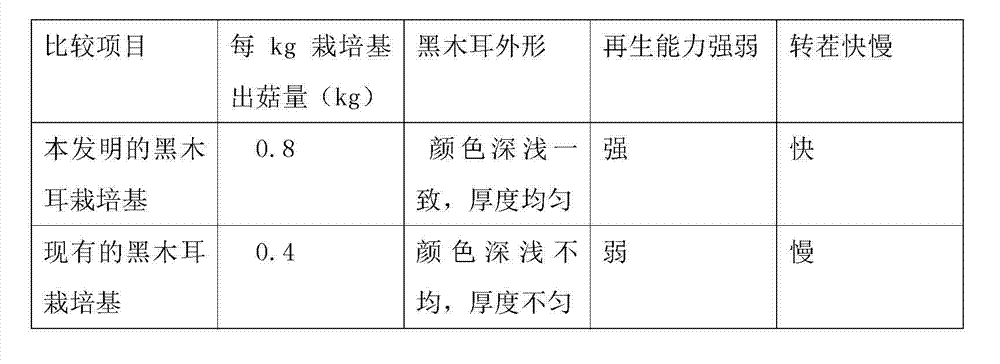

[0027] See the table below for the black fungus cultivation comparison results with the black fungus cultivation base of the present invention and the existing black fungus cultivation base.

[0028]

[0029] Can draw from the table: the black fungus cultivation base provided by the present invention, through test planting, every kilogram of black fungus cultivation base harvests black fungus amount, doubles the output than existing culti...

example 2

[0031] Grind the peanut shells into powder with a pulverizer, weigh 30kg of powdered peanut shells, 18kg of cottonseed skins, 1kg of brown sugar, 0.25Kg of Sophora flavescens, 0.25Kg of Guanzhong, 0.25Kg of lotus leaves, 0.25Kg of onion powder, and 1kg of gypsum powder. After mixing, mix well, then add 50kg of water, mix well, put into high temperature resistant polyethylene plastic bags, 2.5kg per bag; use steam at 100℃ for 20 hours to sterilize under normal pressure; After the bag material is cooled to normal temperature, the black fungus cultivation base is prepared.

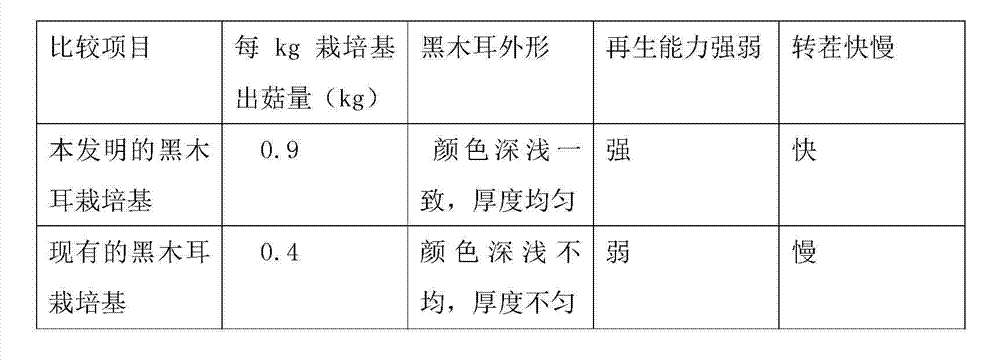

[0032] See the table below for the black fungus cultivation comparison results with the black fungus cultivation base of the present invention and the existing black fungus cultivation base.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com