Preparation method of sargassum fusiforme selenium polysaccharide

A hijiki polysaccharide and selenium polysaccharide technology, which is applied in the direction of drug combination, antineoplastic drugs, allergic diseases, etc., can solve the problems of toxicity, cumbersome operation of selenium polysaccharide, irritating odor reagents, etc., to improve phagocytosis activity, improve The immune function of the body and the effect of no irritating smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

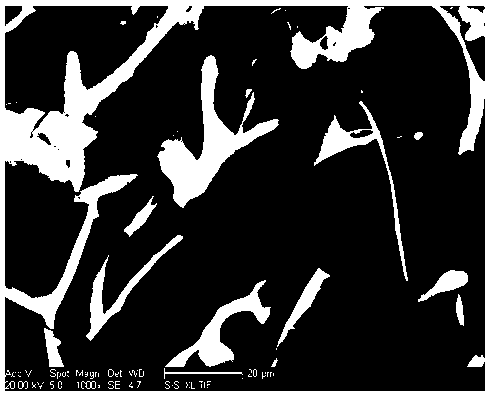

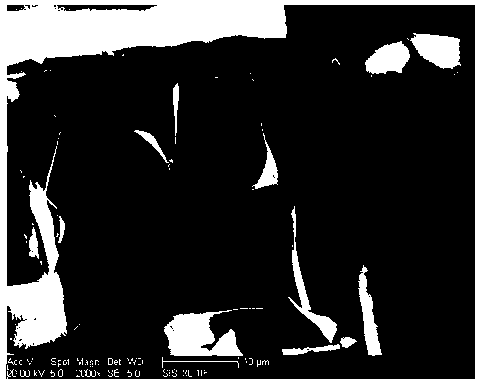

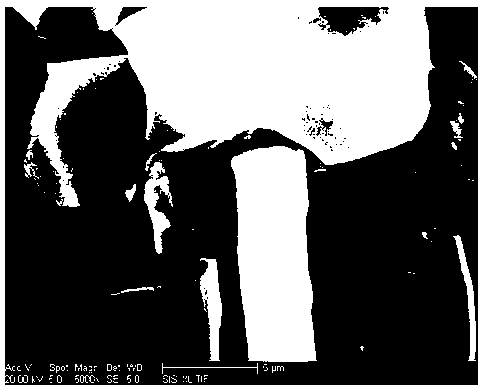

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: the preparation method of hijiki selenium polysaccharide of this embodiment is carried out according to the following steps:

[0037] 1. To 100ml volume fraction of 0.5% HNO 3 Add 1g of hijiki polysaccharide to the aqueous solution to obtain a polysaccharide solution;

[0038] 2. Add sodium selenite to the polysaccharide solution to obtain a mixed solution. The mass ratio of sodium selenite to hijiki polysaccharide in the mixed solution is 0.4 to 1.2g: 1g, and then put it in a water bath at 50°C to 90°C Shake the reaction for 6-10 hours, cool down, and then add NaCO 3 Adjust the pH value to 5-6, centrifuge, and then dialyze until the dialysate is added with ascorbic acid to detect no red color, stop dialyzing, heat, concentrate, and freeze-dry to obtain hijiki selenium polysaccharide.

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of sodium selenite to hijiki polysaccharide in the mixed solution described in step 2 is 0.6g:1g. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass ratio of sodium selenite to hijiki polysaccharide in the mixed solution described in step two is 0.9g:1g. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com