Production process of high-temperature-resistant HNBR (hydrogenated nitrile butadiene rubber) nanocomposite

A nano-composite material and production process technology, applied in the field of rubber, can solve problems such as harsh mining environment and difficulty in meeting mining requirements, and achieve excellent abnormal temperature mechanical properties, excellent anti-aging performance, and high-temperature mechanical properties. The effect of retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

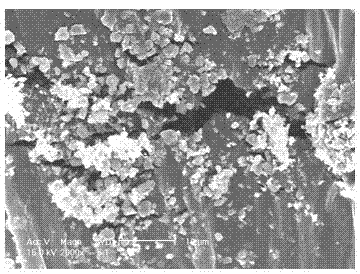

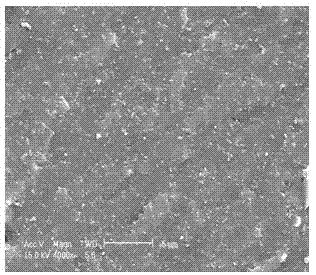

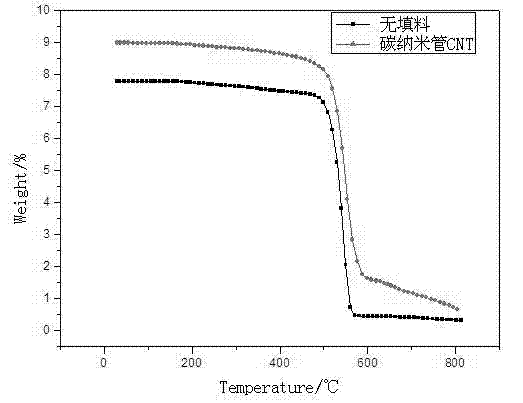

Image

Examples

Embodiment Construction

[0018] 1. Preparation:

[0019] Hydrogenated nitrile rubber (HNBR) 100kg, zinc oxide 5 kg, magnesium oxide 6 kg, stearic acid 1 kg, N550 50 kg, white carbon black 15 kg, carbon nanotubes 30 kg, antioxidant 4 kg, plasticizer 15 kg kg, peroxide Perkadox14-40BD 7 kg, auxiliary cross-linking agent TAIC-70 2 kg.

[0020] Among them, hydrogenated nitrile rubber (HNBR) is produced by Lanxess Chemical, the model is Therban3407; carbon nanotubes are multi-walled carbon nanotubes Baytubes C150 P produced by Bayer; anti-aging agent is produced by Chemtura, anti-aging agent Naugard445; The oxide is produced by Rhine Chemical Company, model Perkadox14-40BD; the co-crosslinking agent is produced by Akzo Nobel Company, model: TAIC-70.

[0021] 2. Production steps:

[0022] 1. Under the condition that the mixing temperature of the ultrasonic mixer is 50°C and the rotation speed is 30rpm, first add hydrogenated nitrile rubber (HNBR), then add zinc oxide, magnesium oxide, stearic acid, N5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com