Cable filling material with low thermal resistance and good tensile properties

A technology of filler and cable material, which is applied in the field of cable filler, can solve problems affecting cable transmission capacity loss, weak stretch resistance, and application, and achieve low thermal resistance, reduce line loss, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

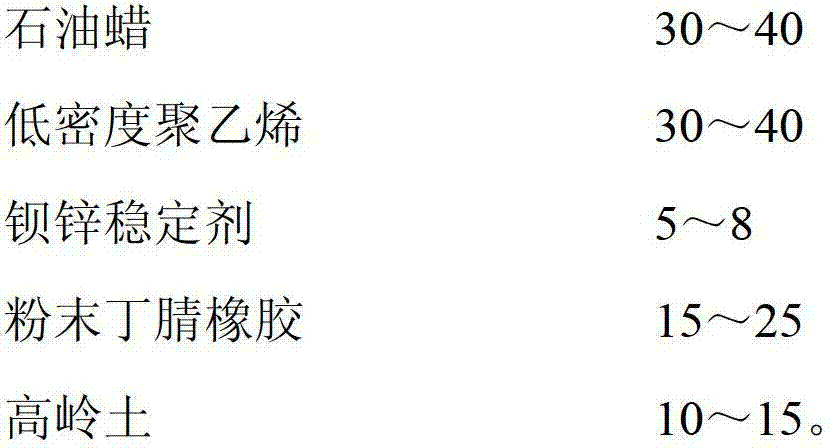

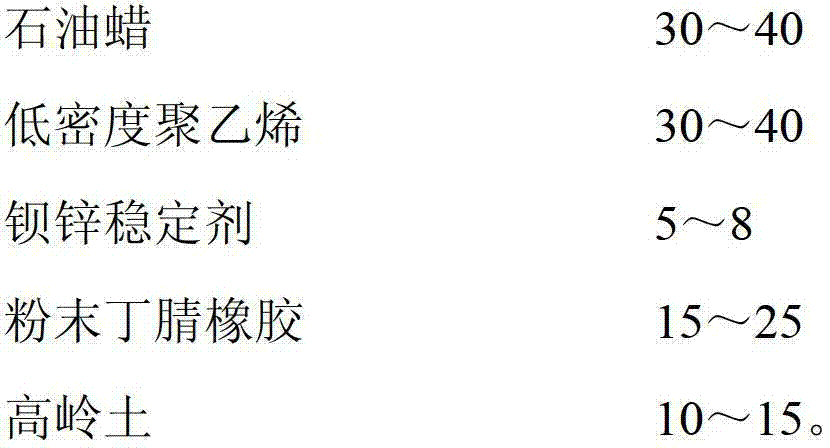

Embodiment 1

[0017] Put 30kg of petroleum wax, 40kg of low-density polyethylene, 5kg of barium-zinc stabilizer, 15kg of powdered nitrile rubber, and 10kg of kaolin into a high-speed mixer and heat and mix for 20 minutes at a heating temperature of 120°C; the mixed material passes through a granulator Extrusion and granulation to obtain the cable material filler.

Embodiment 2

[0019] 35kg petroleum wax, 35kg low-density polyethylene, 6kg barium-zinc stabilizer, 20kg powdered nitrile rubber, 15kg kaolin, 0.7kg lanthanum chloride, 0.2kg praseodymium oxide were put into a high-speed mixer and heated and mixed for 25 minutes, and the heating temperature was 130°C; the fineness of lanthanum chloride and praseodymium oxide is 1200 mesh; the mixed material is extruded and granulated by a granulator to obtain a cable filler.

Embodiment 3

[0021] Put 40kg of petroleum wax, 30kg of low-density polyethylene, 5kg of barium-zinc stabilizer, 12kg of powdered nitrile rubber, 12kg of kaolin, 1kg of lanthanum chloride, and 0.3kg of praseodymium oxide into a high-speed mixer and heat and mix for 30 minutes at a heating temperature of 150 ℃; the fineness of lanthanum chloride and praseodymium oxide is 1200 mesh; the mixed material is extruded and granulated by a granulator to obtain the cable material filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com