Method for producing polyurethane waterproof coating

A polyurethane waterproofing and production method technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of lack of strength, high cost, high toxicity, etc., and achieve the effect of improving comprehensive mechanical properties and solving volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

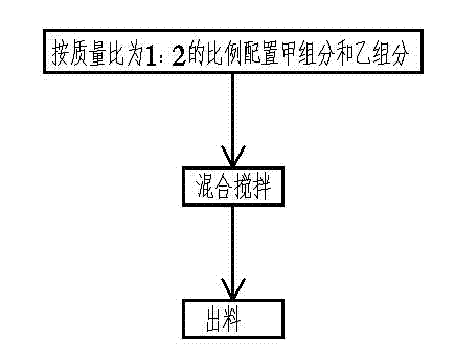

[0020] The production method of the polyurethane waterproof coating is as follows: figure 1 Indicated, including the following steps:

[0021] 1. Configure component A and component B according to the mass ratio of 1:2;

[0022] In Example 1, the A component includes: diphenylmethane diisocyanate: 20% (accounting for the mass fraction of A component); polyether 210: 12%; polyether 220: 40%; polyether Ether 230: 18%; 200# solvent oil 10%;

[0023] The B component includes: coumarone 40% (mass fraction), talc powder 24%, silica fume powder 15%, calcium hydroxide 20%, triethylenediamine 1%.

[0024] 2. Mixing and stirring: put each raw material in the first component into a stirring device, and stir for 0.5 hour at room temperature; carry out preliminary mixing of each raw material in the second component in a mixer with a screw conveying mechanism, after mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com