Flame-retardant two-component polysulfide rubber elastic sealant for hollow glass, and its preparation method

A technology of elastic sealing and liquid polysulfide rubber, applied in chemical instruments and methods, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as harmful to human body, and achieve good flame retardant and fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

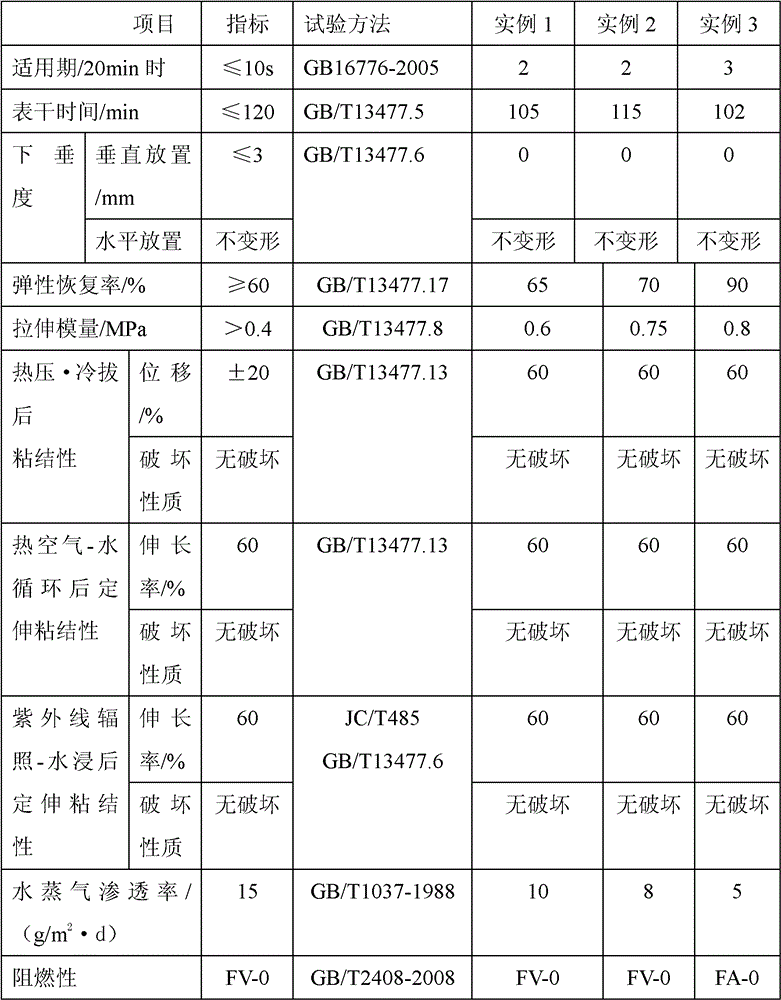

Examples

Embodiment 1

[0020] The parts taken are parts by weight, with 105 parts of liquid polysulfide rubber with an average molecular weight of 2400, 47 parts of phthalate phenylalkyl esters, 85 parts of calcium carbonate, 100 parts of stearic acid modified superfine aluminum hydroxide, chloride Add 13 parts of paraffin wax, 12 parts of superfine zinc borate, and 3.8 parts of γ-(2,3 propylene oxide) propyltrimethoxysilane into the high-speed disperser, heat, stir and vacuumize. When the vacuum degree reaches 0.09Mpa, record the time, stir at a speed of 600-800 rpm for 180 minutes, and control the glue temperature below 85°C to obtain component A of the flame-retardant two-component polysulfide hollow glass elastic sealant.

[0021] 60 parts of active manganese dioxide, 100 parts of phenylalkyl phthalate, 10 parts of carbon black, 14 parts of stearic acid modified superfine aluminum hydroxide, 424 parts of chlorinated paraffin, 4 parts of superfine zinc borate, Accelerator 5 parts (tetramethylthiu...

Embodiment 2

[0024] The parts taken are parts by weight, 118 parts of liquid polysulfide rubber with an average molecular weight of 2400, 15 parts of liquid polysulfide rubber with an average molecular weight of 4000, 40 parts of butyl benzyl phthalate, 68 parts of calcium carbonate, modified stearic acid Add 110 parts of magnesium hydroxide, 5215 parts of chlorinated paraffin, 5 parts of superfine zinc borate, and 3.0 parts of γ-(2,3 propylene oxide) propyl trimethoxysilane into the high-speed disperser, heat, stir and vacuumize . When the vacuum degree reaches 0.09Mpa, record the time, stir at a speed of 600-800 rpm for 180 minutes, and control the glue temperature below 85°C to obtain component A of the flame-retardant two-component polysulfide hollow glass elastic sealant.

[0025] 80 parts of active manganese dioxide, 150 parts of butyl benzyl phthalate, 15 parts of carbon black, 13 parts of accelerator (tetramethylthiuram disulfide), 17 parts of stearic acid modified superfine magnes...

Embodiment 3

[0027] The parts taken are parts by weight, 120 parts of liquid polysulfide rubber with an average molecular weight of 2400, 30 parts of liquid polysulfide rubber with an average molecular weight of 4000, 22 parts of butyl benzyl phthalate, 60 parts of calcium carbonate, modified stearic acid 55 parts of magnesium hydroxide, 60 parts of stearic acid modified superfine basic zinc carbonate, chlorinated paraffin-4210, chlorinated paraffin-5213 parts, 5 parts of superfine zinc borate, 83 parts of magnesium hydroxide, γ-( Add 2.1 parts of 2,3 propylene oxide) propyltrimethoxysilane into the high-speed disperser, heat, stir and vacuumize. When the vacuum degree reaches 0.09Mpa, record the time, stir at a speed of 600-800 rpm for 180 minutes, and control the glue temperature below 85°C to obtain component A of the flame-retardant two-component polysulfide hollow glass elastic sealant.

[0028] 80 parts of active manganese dioxide, 180 parts of butyl benzyl phthalate, 15 parts of car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com