Low carbon cast steel pellet

A cast steel shot and chemical composition technology, which is applied in the field of carbon cast steel shot, can solve the problems of shot shape, metal structure record, poor shot shape, and rising raw material cost, and achieve stable shot blasting ability, small hardness deviation, uniform shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

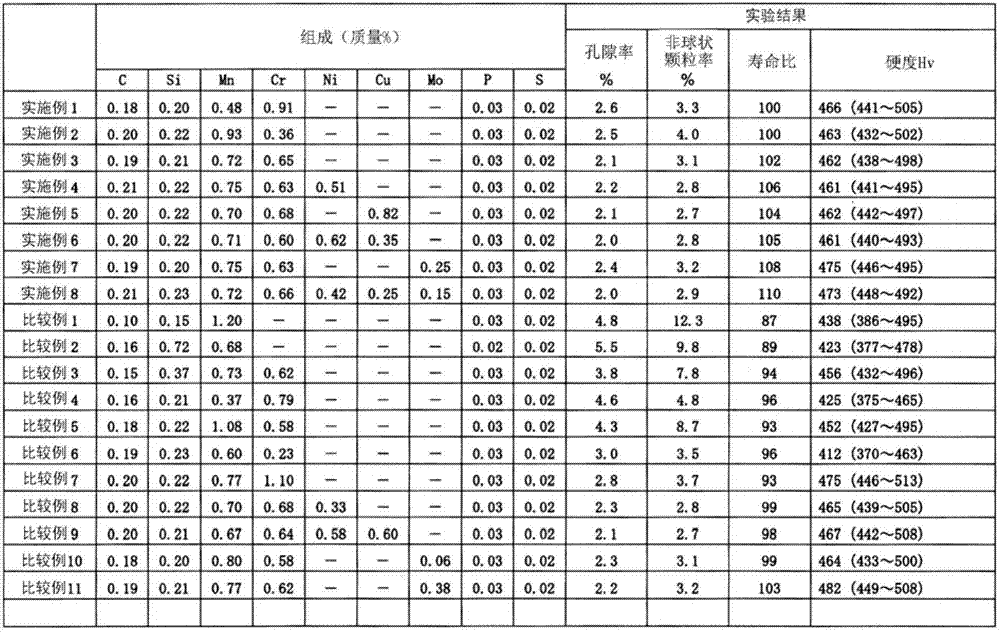

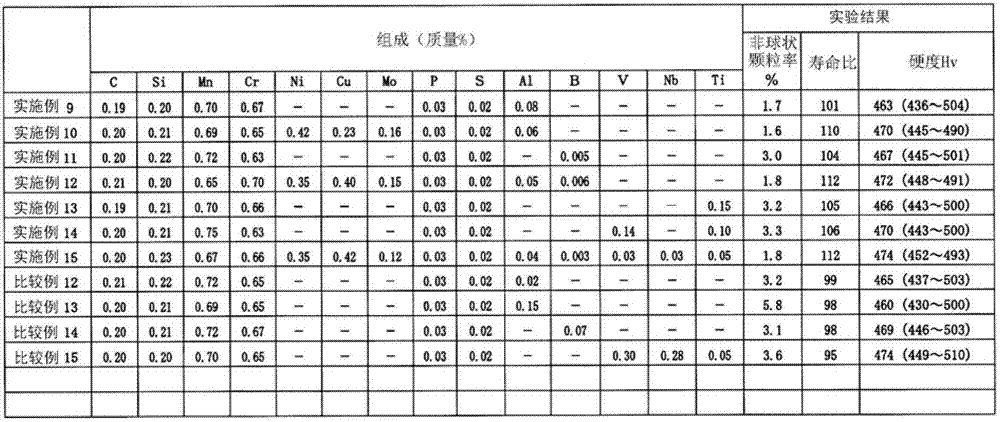

[0076] Embodiment 3 represents the chemical composition of technical scheme 1 or technical scheme 2. In claim 2, in order to stabilize the quality of the pellets, the contents of Si, Mn, and Cr are set within narrower ranges. Compared with Examples 1-2, Example 3 has slightly improved porosity, non-spherical particle ratio, and lifetime ratio. In addition, regarding P and S, since the content of P and S can be reduced to 0.03% or less by using generally available raw materials such as steel chips, the content of P and S is simply omitted so that the content of P and S is 0.03% to 0.05%. % way to adjust the chemical composition to carry out comparative experiments. The metal structure of Example 3 is a bainite structure.

[0077] Embodiment 4 to embodiment 6 represent the chemical composition of technical scheme 3. The above examples show the results of adding Ni and Cu alone or in combination. Compared with Examples 1 to 3, the porosity and hardness are at the same level, b...

Embodiment 7

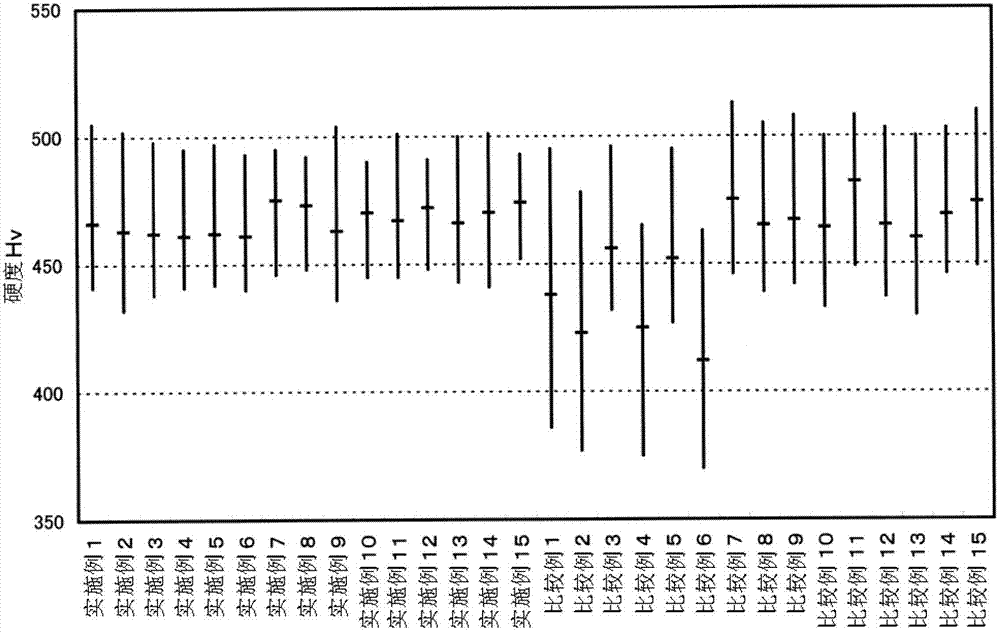

[0080] Embodiment 7 represents the chemical composition of technical scheme 4. This example shows the results of the addition of Mo. Compared with the case of adding Ni and Cu alone or simultaneously, the life ratio is increased, the hardness is also increased by about Hv10, and the variation in hardness is reduced ( figure 1 ). The metal structure of Example 7 is a bainite structure.

[0081] Mo is an element next to Mn that efficiently improves the hardenability of steel, and makes the metal structure finer and more uniform. On the other hand, in Comparative Example 10 in which the Mo content was less than 0.10%, no changes in the hardness and life ratio were observed, and in Comparative Example 11 in which the Mo content exceeded 0.30%, the hardness was further improved. Relatively, the life ratio is reduced. The metal structures of Comparative Examples 10 to 11 were bainite structures.

Embodiment 8

[0082] Embodiment 8 represents the chemical composition of technical scheme 5. Example 8 shows the results in the case where Ni and Cu were added simultaneously and Mo was added. Compared with Examples 4 to 6, the service life was relatively high and the hardness was increased, and the variation in hardness was also reduced. The metal structure of Example 8 is a bainite structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com