Novel molten aluminum electrolytic cell

An electrolytic cell and aluminum melting technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low gas oxygen purity, affecting work efficiency, and mixed with harmful gases, so as to achieve convenient operation and increase Productivity, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

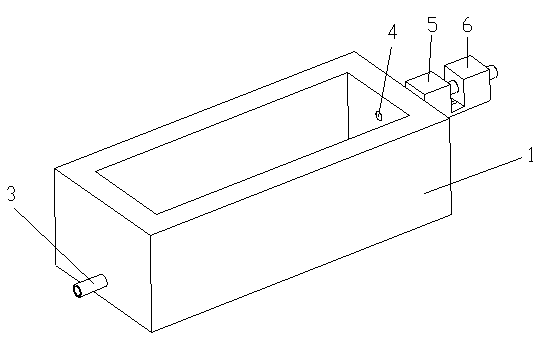

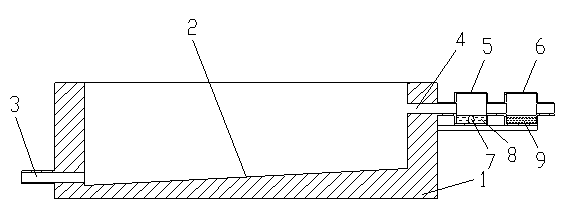

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , 2 A new electrolytic cell for melting aluminum according to the present invention is shown, which includes the electrolytic cell body 1; the bottom 2 of the electrolytic cell has a slope; the lowest part of the bottom 2 of the electrolytic cell is provided with an outlet pipe 3 for molten aluminum The upper end of the other side of the electrolytic cell body 1 is provided with a gas outlet pipe 4; the gas outlet pipe 4 is provided with a carbon dioxide purifier 5 and a nitrogen purifier 6; calcium oxide 7 and Water 8; activated carbon adsorbent 9 is housed in the nitrogen purifier 6.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] In the novel aluminum-melting electrolytic cell of the present invention, since the bottom of the electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com