Pneumatic opposed-piston engine

A technology of opposed pistons and compressed air pistons, which is applied to combustion engines, machines/engines, mechanical equipment, etc., can solve problems such as complex structures, and achieve high efficiency and simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

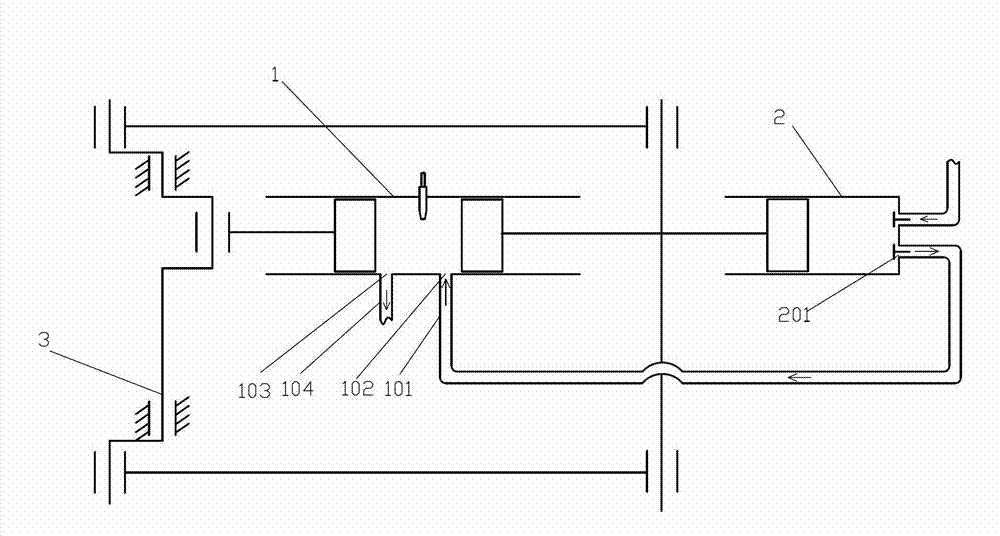

[0039] Such as figure 1 The shown compressed gas opposed piston engine comprises an internal gas cylinder 1, a compressed gas cylinder 2 and a crankshaft 3, two internal combustion pistons are oppositely arranged in one of the internal gas cylinders 1, and a compressed gas piston is arranged in the compressed gas cylinder 2, the The compression piston is connected with one internal combustion piston, one internal combustion piston in the internal gas cylinder 1 is connected to the connecting rod journal of the crankshaft 3 through a connecting rod, and the other internal combustion piston is connected to the crankshaft 3 through another connecting rod. The other connecting rod journals of the crankshaft 3 are rotatably connected, and there is a phase difference between the two types of connecting rod journals. Connected, the displacement of the compressor cylinder 2 is greater than the displacement of the internal gas cylinder 1 .

[0040] Wherein, the compressed gas piston ...

Embodiment 2

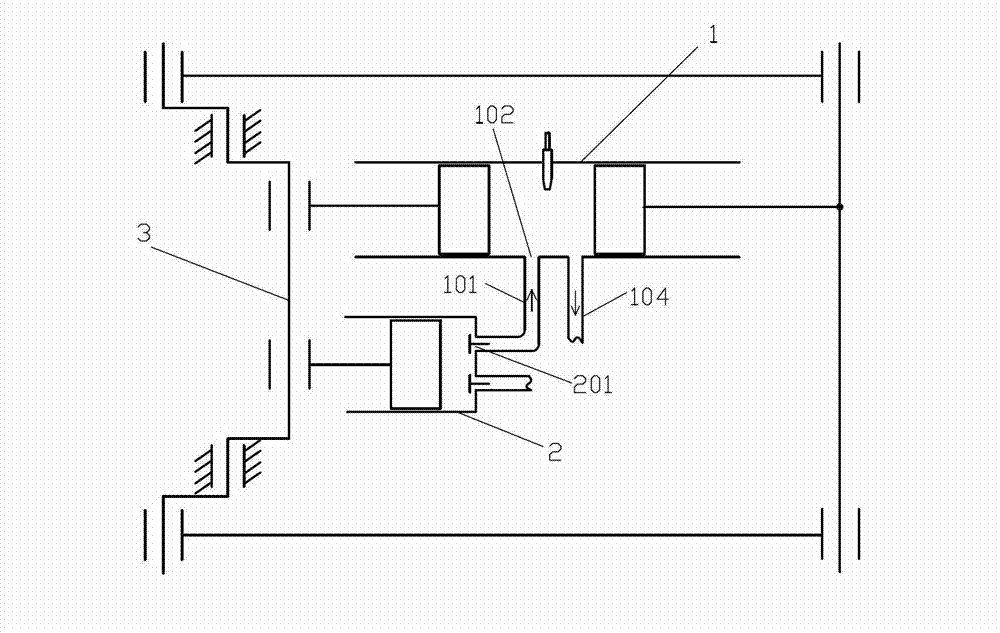

[0045] Such as figure 2 The difference between the compressed-gas opposed-piston engine shown in Embodiment 1 is that the compressed gas piston is connected to the internal combustion piston close to the crankshaft 3, wherein the internal combustion cylinder 1 and the internal combustion piston constitute The engine has a compression ratio of 8.

Embodiment 3

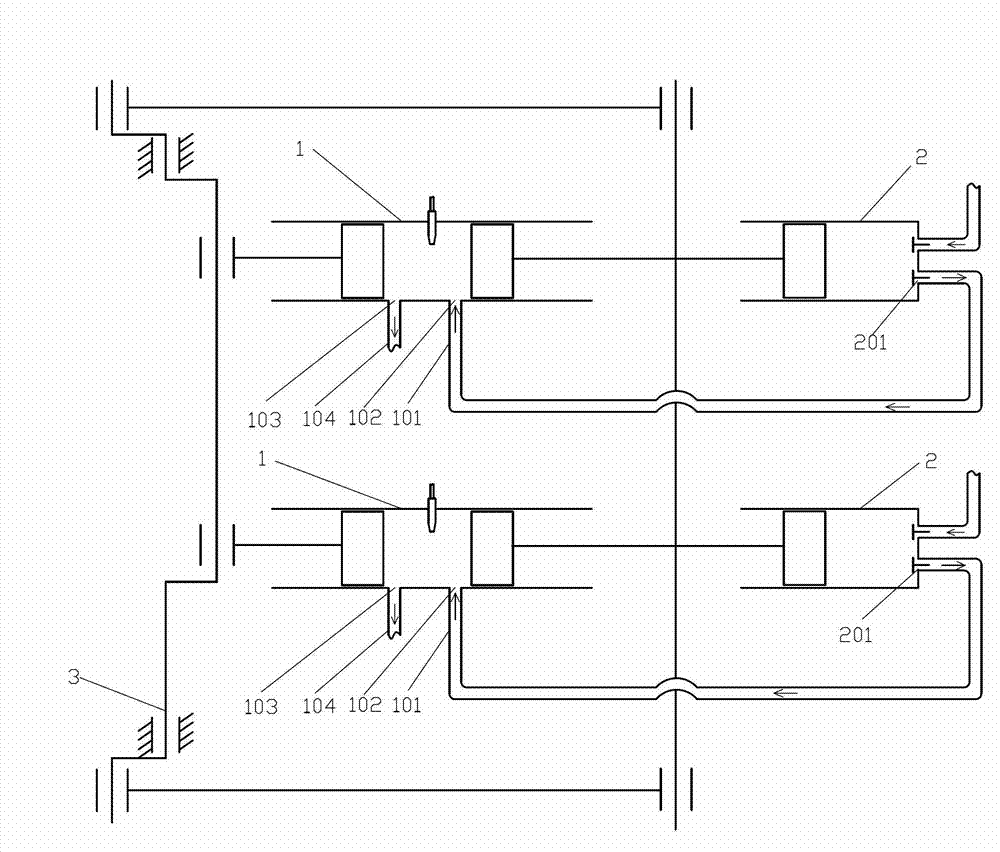

[0047] Such as image 3 The difference between the compressed air opposed piston engine and Embodiment 1 is that the compressed air opposed piston engine includes two internal gas cylinders 1 and two compressed air cylinders 2, and the two internal gas cylinders 1 are parallel It is set that two internal combustion pistons are arranged opposite to each other in each of the internal combustion cylinders 1, and the compression pistons are respectively arranged in each of the compression cylinders 2, and one of the internal combustion pistons in each of the internal gas cylinders 1 The internal combustion piston is connected with one said compression piston, and the sum of the displacements of the two compression cylinders 2 is greater than the sum of the displacements of the two internal combustion cylinders 1, and the engine formed by the internal combustion cylinder 1 and the internal combustion piston The compression ratio is 12.

[0048] Optionally, the opposed piston engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com