Servo electric cylinder

A servo electric cylinder and cylinder block technology, applied in the field of servo electric cylinders and electric cylinders, can solve the problems of large wear of the overrunning clutch, high cost of manufacturing and installation, complex locking structure, etc., and achieve stable displacement limitation, long service life, Combined with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

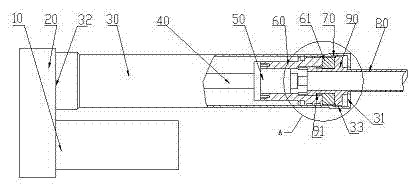

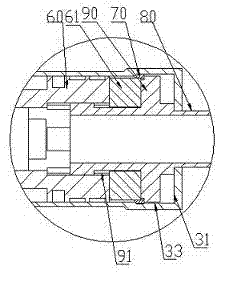

[0043] Such as figure 1 Shown is the servo electric cylinder of the present invention, including

[0044] The cylinder body 30 is a hollow pipe body having an open end 32 and a closed end 31, and the closed end 31 of the cylinder body has an opening;

[0045] Lead screw 40, described lead screw 40 is placed in described cylinder 30, and one end of described lead screw 40 is fixedly connected with the output end of transmission device 20 through the cylinder open end 32 of described cylinder;

[0046] a lead screw nut 50, the lead screw nut 50 cooperates with the lead screw 40 and can reciprocate along the axis of the lead screw 40; and

[0047] The piston 60 is a tubular cylinder, the piston 60 is coaxially socketed and fixed on the screw nut 50 , and the outer wall of the piston 60 is slidingly matched with the inner wall of the cylinder body 30 ;

[0048] Piston rod 80, the piston rod 80 passes through the opening of the closed end 31 of the cylinder...

Embodiment 2

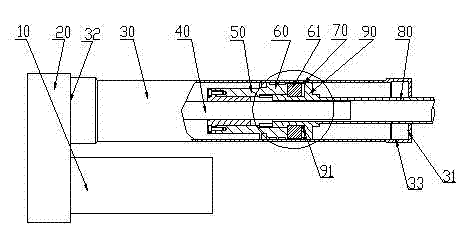

[0066] Such as Figure 5 Shown is the servo electric cylinder in this embodiment, including

[0067] The cylinder body 30 is a hollow pipe body having an open end 32 and a closed end 31, and the closed end 31 of the cylinder body has an opening;

[0068] Lead screw 40, described lead screw 40 is placed in described cylinder 30, and one end of described lead screw 40 is fixedly connected with the output end of transmission device 20 through the cylinder open end 32 of described cylinder;

[0069] a lead screw nut 50, the lead screw nut 50 cooperates with the lead screw 40 and can reciprocate along the axis of the lead screw 40; and

[0070] The piston 60 is a tubular cylinder, the piston 60 is coaxially socketed and fixed on the screw nut 50 , and the outer wall of the piston 60 is slidingly matched with the inner wall of the cylinder body 30 ;

[0071] Piston rod 80, the piston rod 80 passes through the opening of the closed end 31 of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com