Substrate carrier for mounting substrates

A substrate carrier and substrate technology, which is used in semiconductor devices, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve problems such as being unsuitable for high-temperature processes, and achieve the effect of uniform temperature change curve and short process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

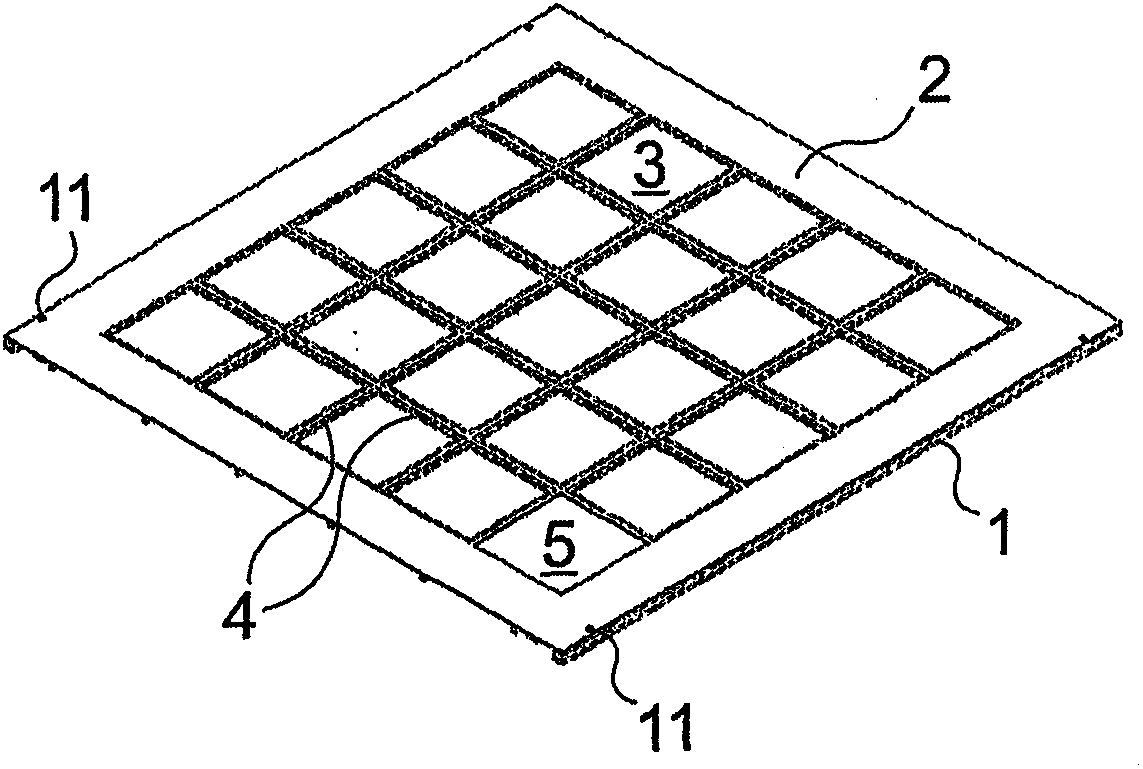

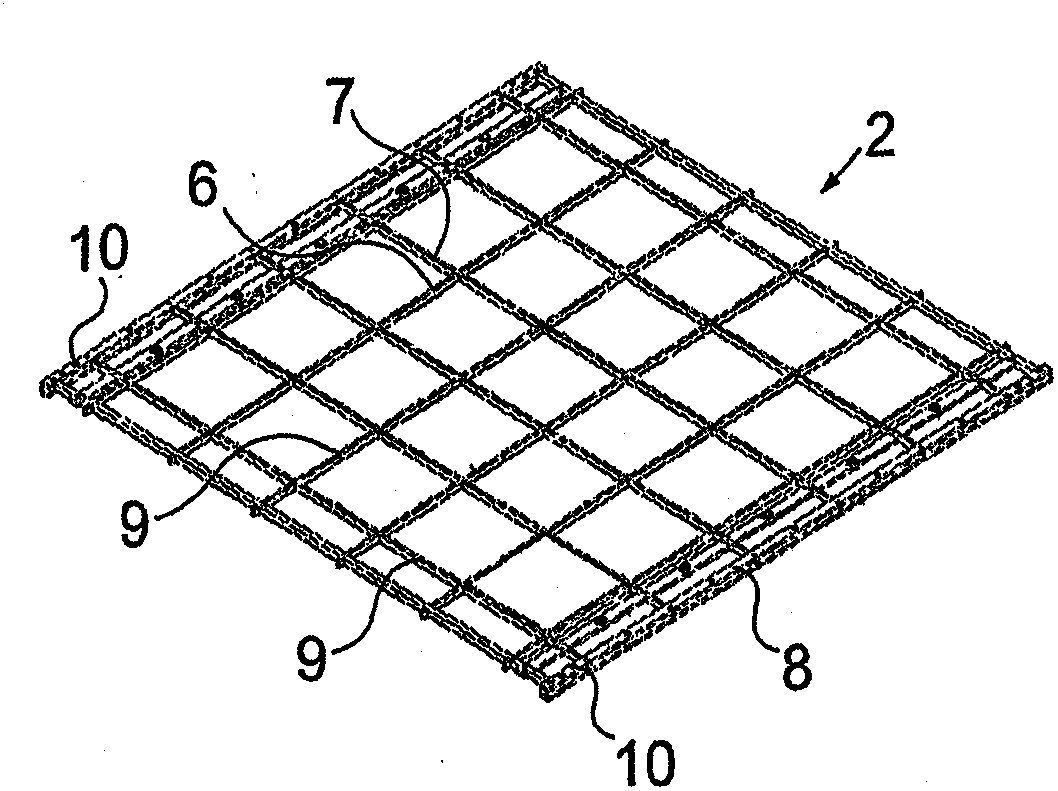

[0019] exist figure 1 , a substrate carrier according to an embodiment is shown in a perspective view from above. The substrate carrier basically consists of a lower carrier frame 1 and a substrate holder 2 lying flat on the carrier frame 1 . For example 5×5 recesses in the form of openings 3 are machined into the substrate holder 2, said recesses having lateral brackets 4 for holding rectangular solar cell crystals with dimensions 156×156 mm in dimensions 158×158 mm. Circle 5. exist figure 1 Only the solar cell wafer 5 is placed in the lower opening 3 . The plate-shaped substrate holder 2 has a thickness of 1.2 mm, and the bracket 4 is sunk by 0.5 mm relative to the upper side of the substrate holder 2 so that the solar cell wafer 5 is reliably positioned in the opening 2 with a thickness of 0.5 mm.

[0020] The substrate holder 2 covers the carrier frame 1 as a whole, so that the heat source arranged above is shielded. If required, the lateral regions of the carrier fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com