Positioning and clamping mechanism for a plurality of drill holes

A technology for positioning and clamping and positioning keys, which is used in positioning devices, clamping, metal processing mechanical parts, etc., can solve the problems of low equipment utilization, high work intensity, and high equipment costs, reducing work intensity and improving processing efficiency. , the effect of improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

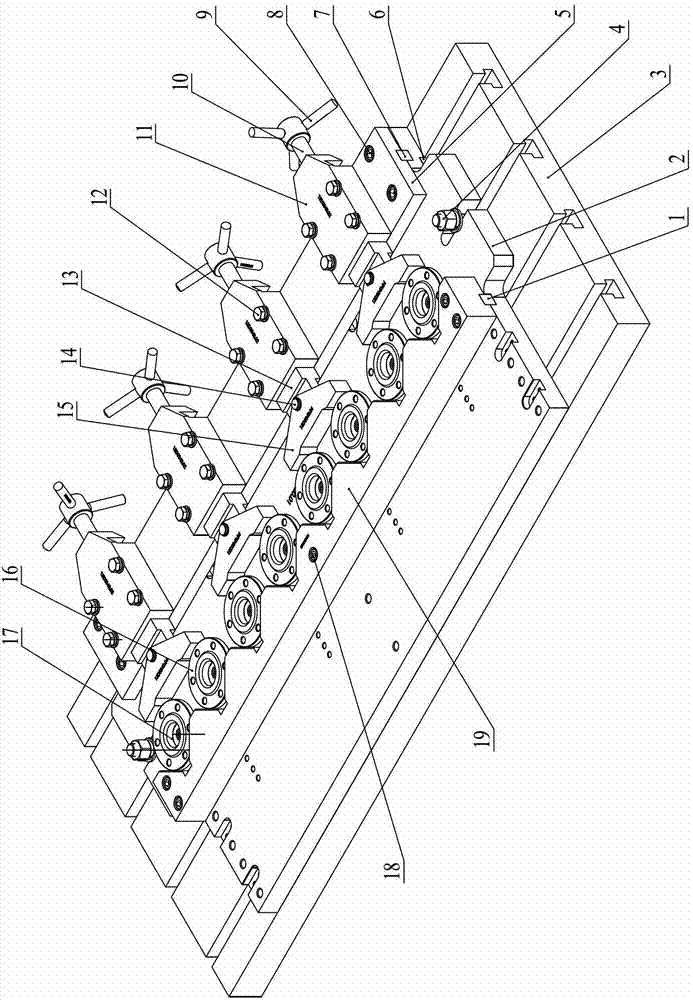

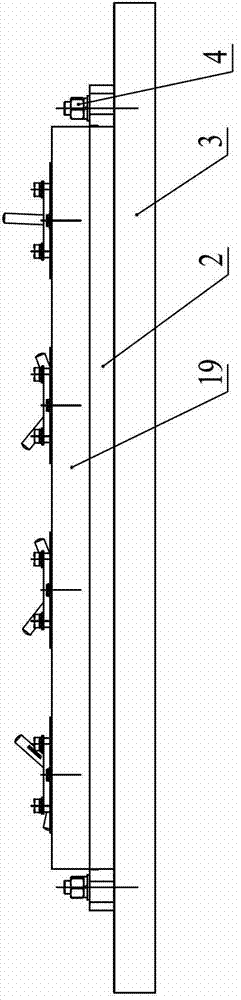

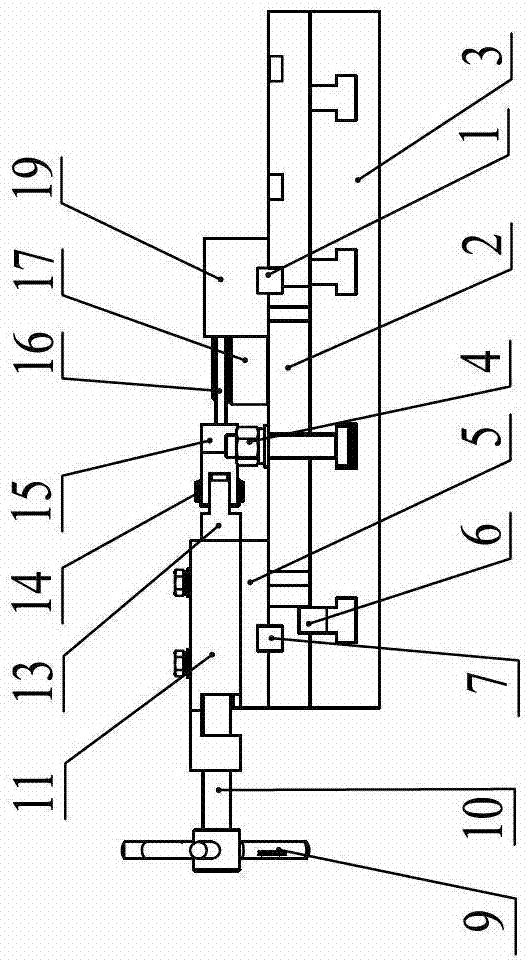

[0015] As shown in the figure: the multi-piece drilling positioning and clamping mechanism in the embodiment is mainly composed of a first positioning key 1, a clamp body 2, a machine tool table 3, a T-bolt 4, a backing plate 5, a second positioning key 6, and a second positioning key 6. Three positioning key 7, screw 8, handle 9, compression bolt 10, support body 11, bolt 12, push plate 13, cylindrical pin 14, pressure plate 15, workpiece 16, positioning plate 17, screw 18 and fixed V-shaped block 19 and other components.

[0016] like Figure 1~Figure 4 As shown, the clamp body 2 cooperates with the T-shaped groove in the machine table 3 through the second positioning key 6 and locks it with the T-shaped bolt 4; the backing plate 5 cooperates with the positioning groove on the clamp body 2 through the third positioning key 7 and locks it. The screw 8 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com