Flame-retardant phenol formaldehyde epoxy composite material

A composite material, phenolic epoxy technology, which is applied in the field of polymer materials, can solve the problems that phenolic epoxy materials cannot provide flame retardancy, and achieve the effects of convenient molding, high strength, and good heat resistance

Inactive Publication Date: 2013-01-09

CHANGSHU YONGXIANG ELECTROMECHANICAL

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Because novolac epoxy composite materials have good comprehensive properties, they are widely used by people, but novolac epoxy materials themselves cannot provide good flame retardancy. Therefore, it is necessary to improve their flame retardancy and at the same time ensure that they have Properties such as heat deformation resistance, bending strength, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

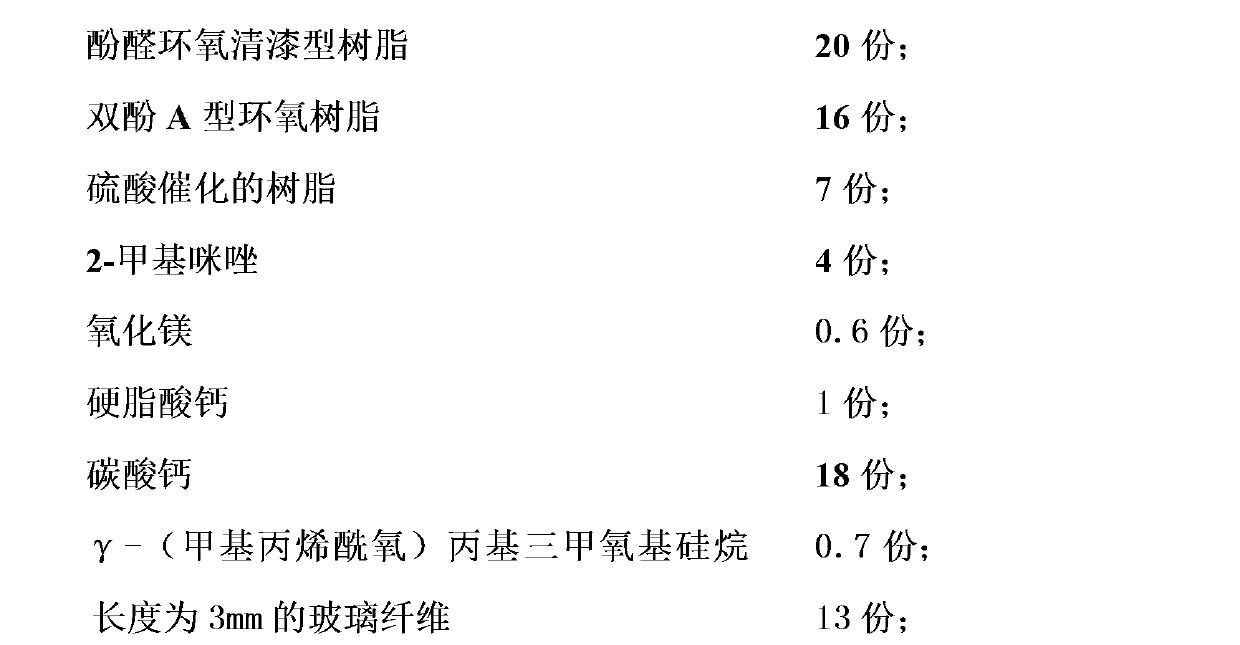

Embodiment 1

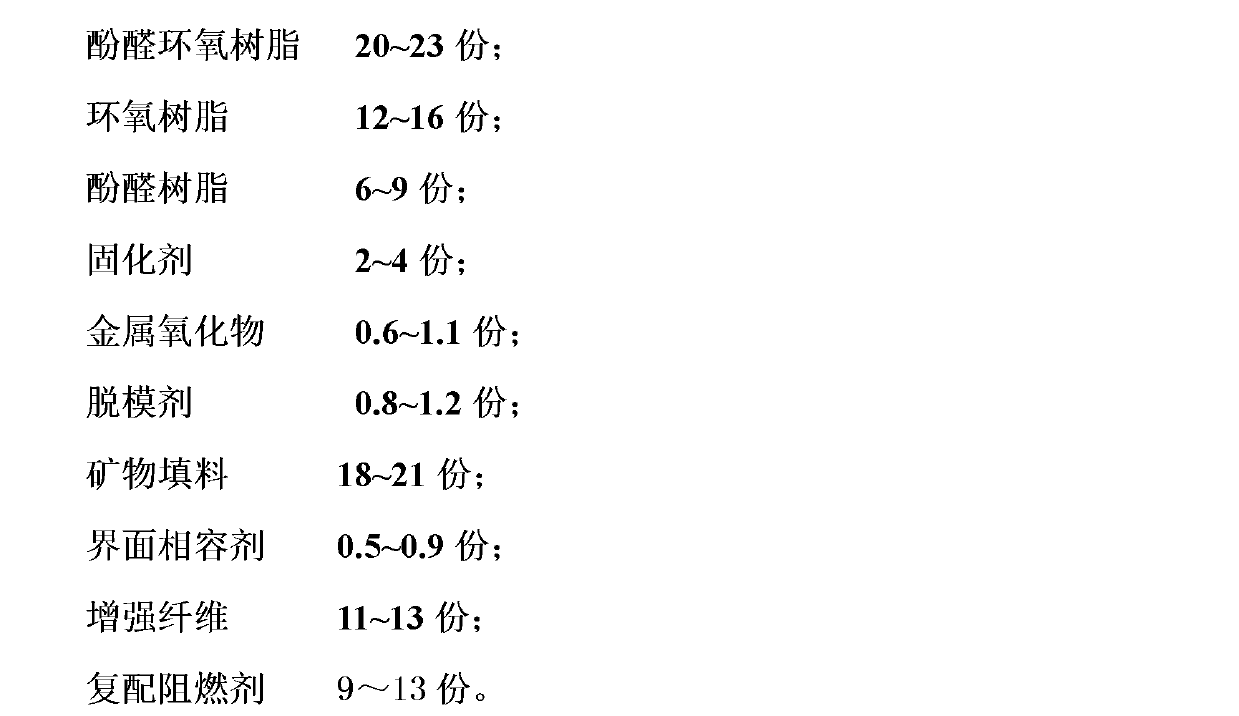

[0017]

[0018] 10 parts of a compound flame retardant composed of decabromodiphenyl ether and melamine urate, each with a mass percentage of 50%.

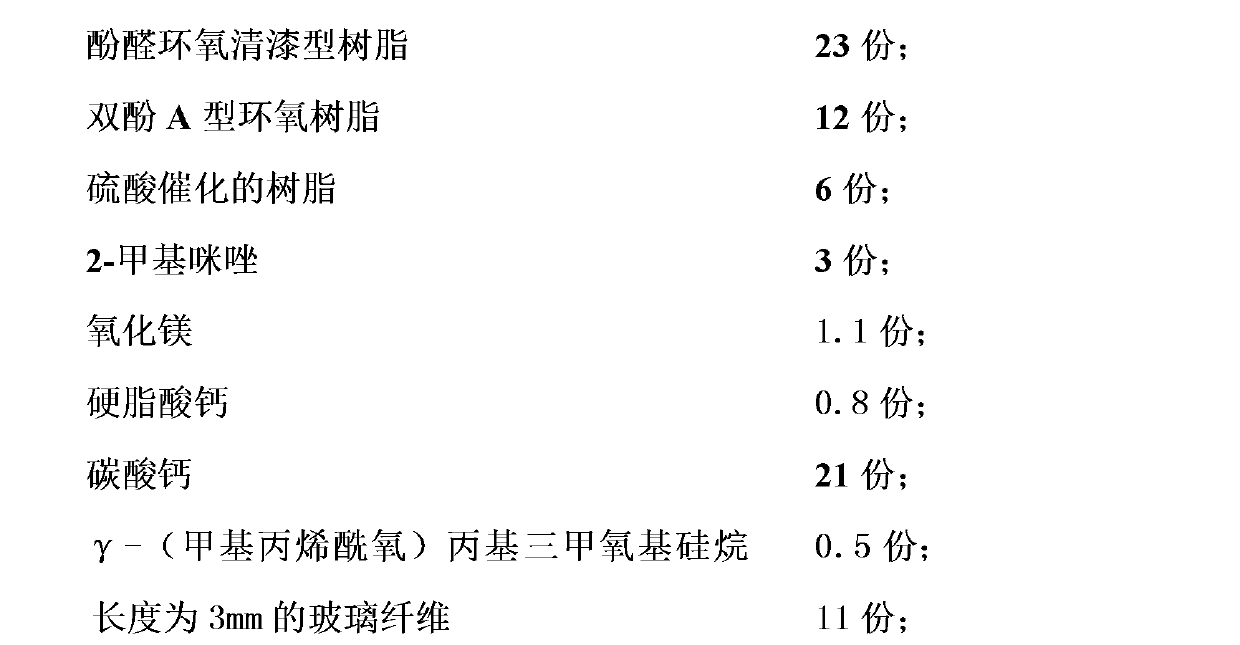

Embodiment 2

[0020]

[0021] 9 parts of compound flame retardants composed of 50% decabromodiphenyl ether and melamine urate.

Embodiment 3

[0023]

[0024] 11 parts of a compound flame retardant composed of decabromodiphenyl ether and melamine urate, each of which is 50% by mass.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a flame-retardant phenol formaldehyde epoxy composite material, belonging to the technical field of high polymer materials. The flame-retardant phenol formaldehyde epoxy composite material comprises 20-23 parts of phenol formaldehyde epoxy resin, 12-16 parts of epoxy resin, 6-9 parts of phenol formaldehyde resin, 2-4 parts of curing agent, 0.6-1.1 parts of metal oxide, 0.8-1.2 parts of releasing agent, 18-21 parts of mineral filler, 0.5-0.9 part of interface compatilizer, 11-13 parts of reinforcing fiber and 9-13 parts of compound flame retardant. The flame-retardant phenol formaldehyde epoxy composite material has the advantages of favorable heat resistance and high strength, and is convenient for molding. The test proves that the bending strength is 88 MPa, the heat-deformation temperature is 240 DEG C, and the flame retardancy reaches Grade V-0 (UL-94-V-0 1.6mm).

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a flame-retardant phenolic epoxy composite material. Background technique [0002] Because novolac epoxy composite materials have good comprehensive properties, they are widely used by people, but novolac epoxy materials themselves cannot provide good flame retardancy. Therefore, it is necessary to improve their flame retardancy and at the same time ensure that they have Properties such as heat deformation resistance, bending strength, etc. Contents of the invention [0003] The task of the present invention is to provide a flame-retardant novolak-epoxy composite material which not only has good mechanical properties but also has outstanding flame-retardant properties. [0004] The object of the present invention is achieved like this, a kind of fire-retardant novolac epoxy composite material, comprises following component: [0005] [0006] In a spec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L63/04C08L63/02C08L61/06C08K13/04C08K5/3445C08K3/22C08K5/098C08K3/26C08K7/14C08K5/03C08K5/3492

Inventor 方云祥

Owner CHANGSHU YONGXIANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com