Magnesium alloy and device and method for machining magnesium alloy handrail ring of wheelchair

A wheelchair armrest and magnesium alloy technology, applied to magnesium alloy materials and their application fields, can solve the problems of low plastic deformation capacity, stress concentration, material failure, etc., and achieve excellent conduction and heat dissipation performance, small elastic modulus, and fine texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

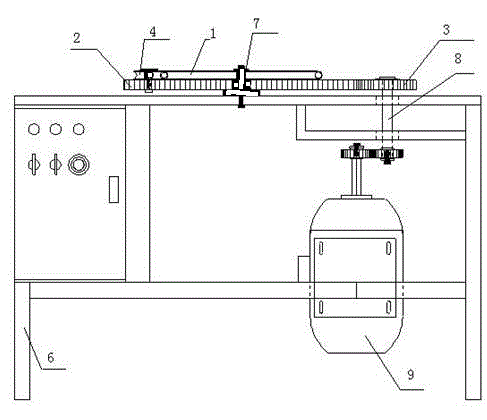

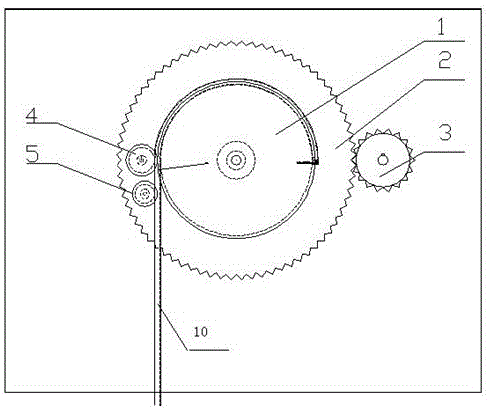

[0033] figure 1 , figure 2 As shown, the device for processing the magnesium alloy wheelchair armrest ring of the present invention includes a bracket 6, which is characterized in that the fixed sheave 1 is arranged on the bracket 6, and the fixed sheave 1 is fastened to the central fixed shaft 7 through a keyway. A toothed disc 2 is arranged below the fixed sheave 1, and the toothed disc 2 is connected with the central fixed shaft with a bearing. The driving gear 3 and the toothed disc 2 are meshed according to the rotation ratio of 1:4, and a speed-regulating motor 9 is arranged under the driving shaft 8, and the speed-regulating motor 9 adjusts the speed of the toothed disc 2 as required. The adjustable pressing wheel 4 is installed on the chainring 2 by a fixed shaft, and the pressing wheel 4 is close to the sheave 1. A guide wheel 5 is set at the front end of the pressing wheel 4 at 80 mm, and a pipe clamp is set on the rim of the fixed sheave 1 and at a distance of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com