Vertical wide-range high-precision optical plane testing device

An optical plane and testing device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of large influence of measurement results, high equipment processing requirements, and achieve the effects of light weight, reduced testing environment requirements, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

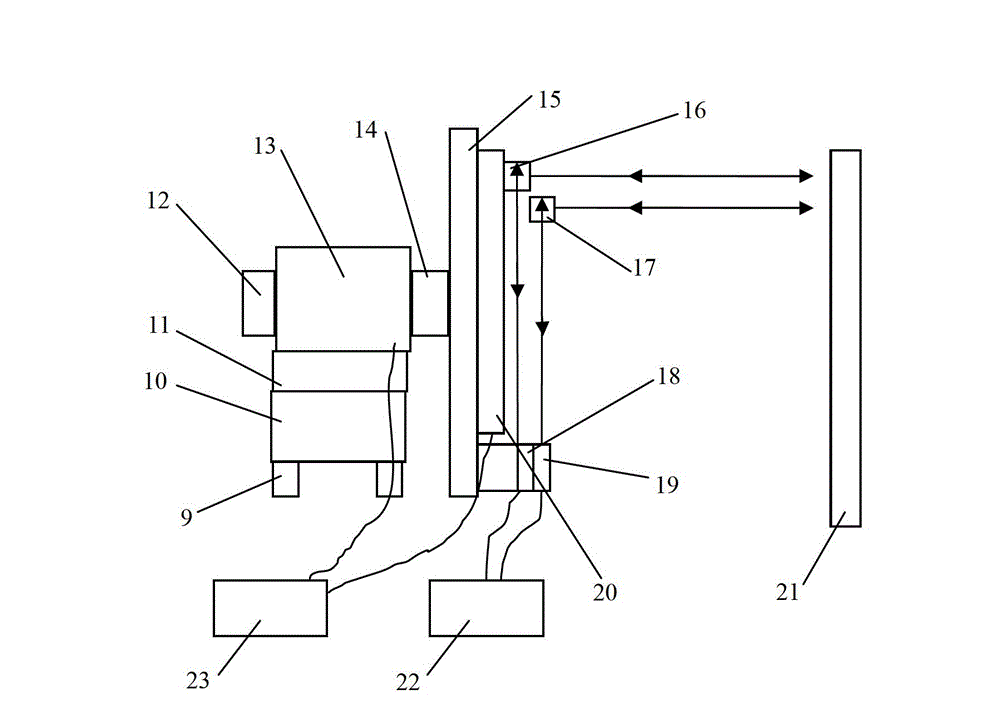

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] like image 3 As shown, the vertical large-scale high-precision optical plane testing device of the present invention includes: four lifting legs 9, a supporting base 10, a horizontal turntable 11, a counterweight 12, a vertical precision turntable 13, a connecting shaft 14, and a long guide rail Carrier plate 15, the first pentaprism 16, the second pentaprism 17, the first Hardemann wavefront tester 18 with self-collimating light source, the second Hardemann wavefront tester 19 with self-collimating light source, Long guide rail 20, electric control system 23 and data acquisition and analysis system 22; four lifting legs 9 are evenly distributed at the four corners of the support base 10, the horizontal turntable 11 is placed on the support base 10, and the vertical precision turntable 13 Placed on the horizontal turntable 11, the counterweight 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com