Piezoresistive sensor for internal pressure detection of expressway road bed

A pressure sensor, highway technology, applied in the sensor application field, can solve the measurement sensitivity and measurement result error, the instrument amplifier does not automatically clear the zero point offset voltage of the piezoresistive pressure sensor, and cannot provide a constant current source or constant voltage for the pressure sensor Source and other issues to achieve the effect of preventing corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments.

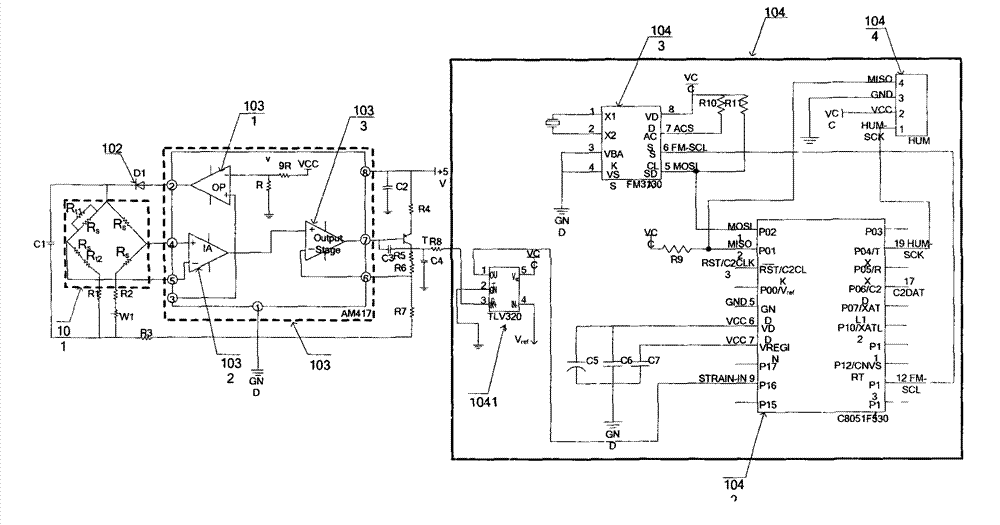

[0027] figure 1 It shows the structure diagram of the piezoresistive sensor circuit for automatically correcting zero point and temperature offset in this embodiment.

[0028] Such as figure 1 As shown, the circuit includes: a zero point temperature compensation circuit 101 , a sensitivity temperature compensation circuit 102 , a proportional voltage conversion circuit 103 , and a zero point calibration value storage circuit 104 . The zero calibration value storage circuit 104 includes: a comparator 1041 , a controller 1042 , a memory 1043 , and a temperature and humidity sensor 1044 .

[0029] The zero-point temperature compensation circuit 101 is a thermistor connected in series and in parallel in the bridge structure of the pressure sensor. where 4 resistors R s is the bridge arm resistance of the pressure sensor, and the series resistance R t2 It mainly plays the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com