Bow and arrow testing machine

A technology for testing machines and bows and arrows, which is applied in the field of sports equipment, and can solve the problems of not being able to meet the requirements at one launch site, insufficient adjustment range of launch pitch angle, and inability to test recurve bows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained in conjunction with the drawings:

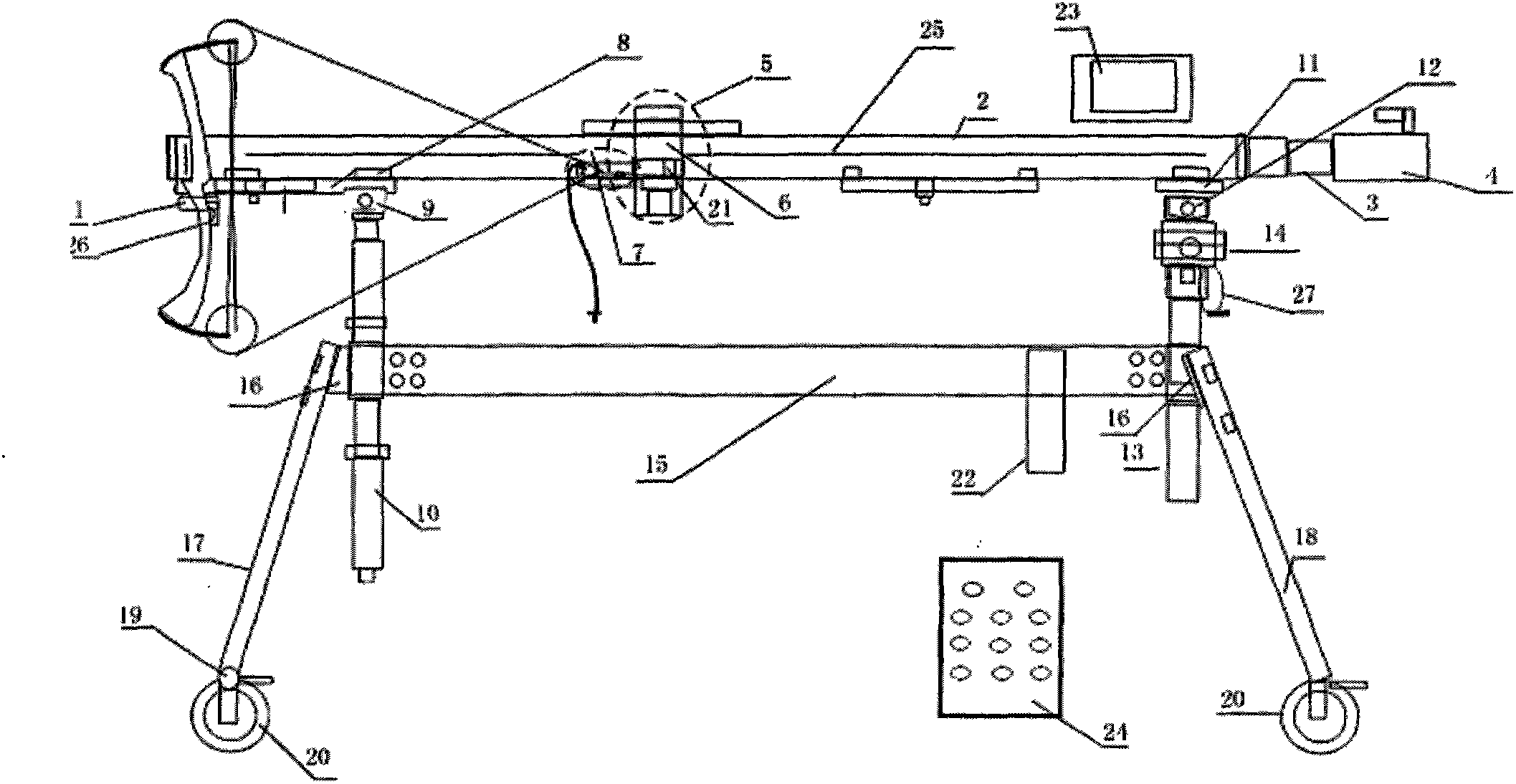

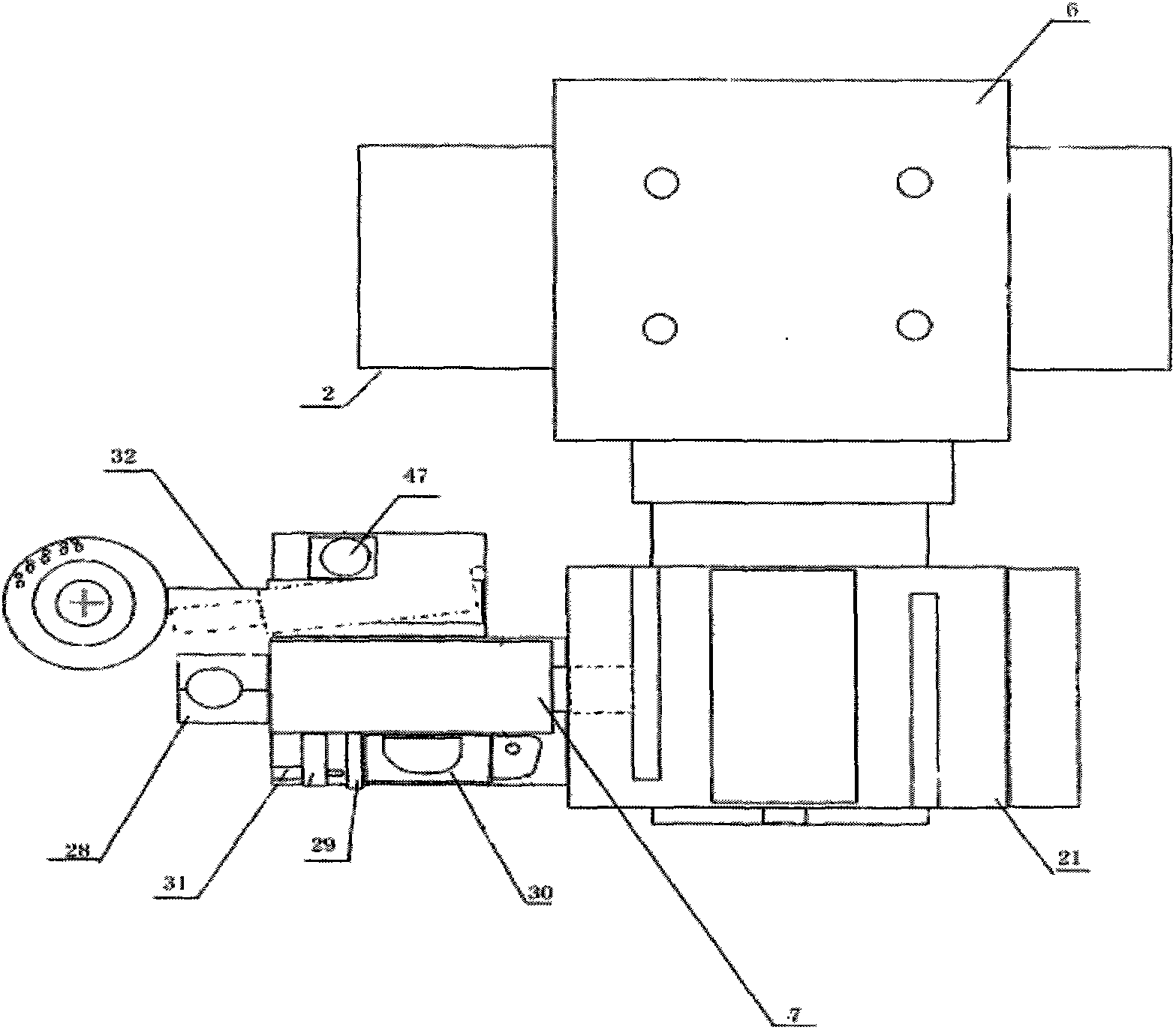

[0035] Such as figure 1 As shown, it is a schematic diagram of the bow opening state of a bow and arrow testing machine, including the bow hanging frame 1 at the front end of the linear motion unit 2, and the tail end of the linear control unit 2 is connected to the servo motor 4 through the coupling 3. The component 5 is connected to the linear motion unit 2 through the bow opening assembly connecting block 6; the spreading assembly 7 is located at the front end of the bow opening assembly 5; the lower position of the front of the linear motion unit 2 passes through the front base 8 and the front pitch The adjustment joint 9 is connected to the front column 10, and the lower position of the rear part is connected to the horizontal angle fine adjustment platform 14 on the rear column 13 through the rear base 11 and the rear pitch adjustment joint 12; the front end position of the main beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com