Light-emitting diode encapsulating structure and manufacturing method thereof

A technology for light-emitting diodes and packaging structures, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of wire falling off, the complicated and tedious process of bonding and bonding, and affecting the production yield of light-emitting diode packaging structures, so as to facilitate heat dissipation. , the effect of the production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

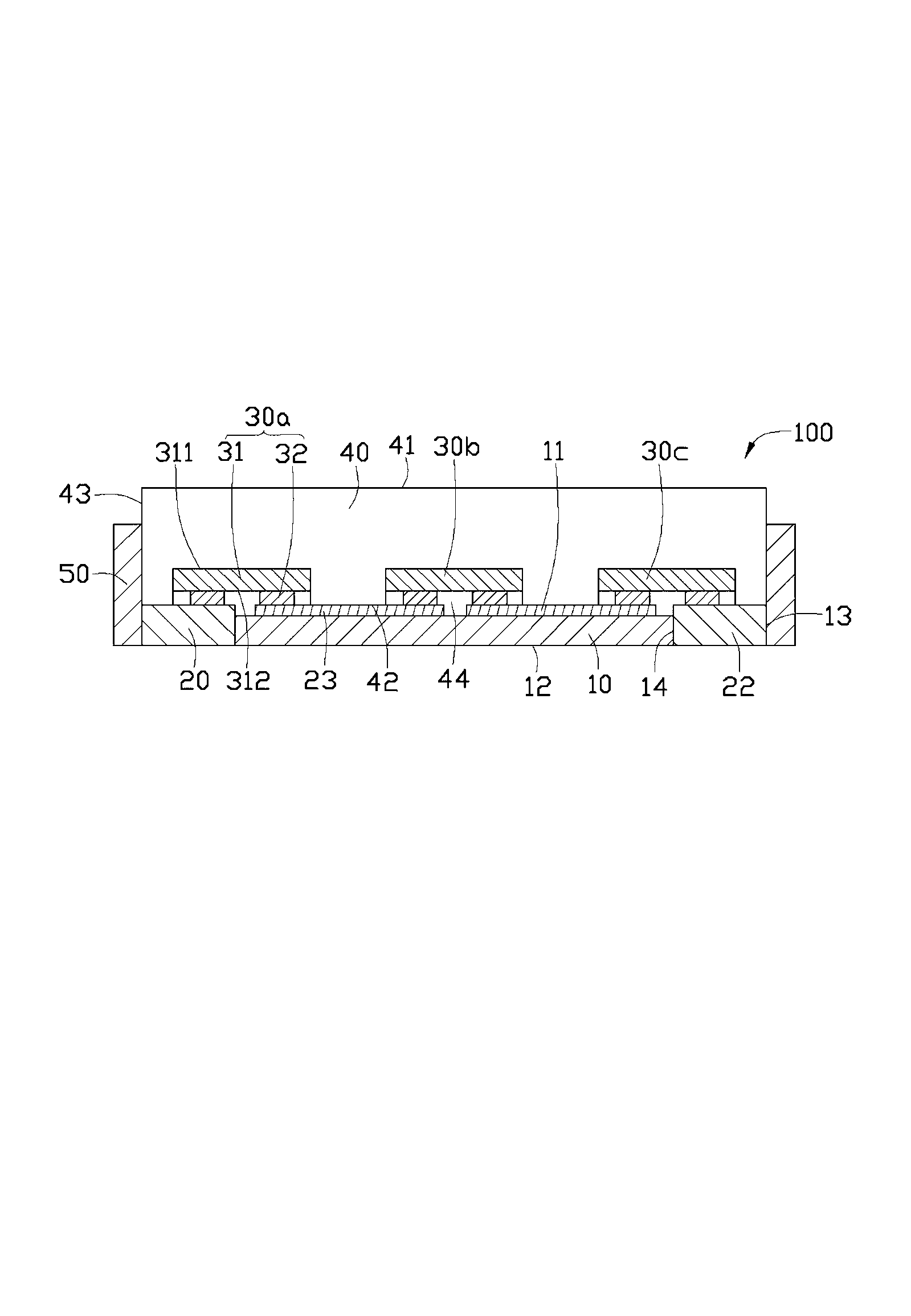

[0021] See figure 1 , the light emitting diode packaging structure 100 provided by the first embodiment of the present invention includes a substrate 10, an electrode 20, a light emitting diode 30 fixed on the electrode 20 and electrically connected to the electrode 20, a package body 40 covering the light emitting diode 30 and a reflector Section 50.

[0022] The substrate 10 is roughly in the shape of a rectangular plate, and the substrate 10 includes an upper surface 11 , a lower surface 12 opposite to the upper surface 11 , and several side surfaces 13 connecting the upper surface 11 and the lower surface 12 . At least two through holes 14 are opened on the substrate 10 . In this embodiment, there are two through holes 14 , the through holes 14 are respectively close to the opposite side surfaces 13 of the substrate 10 , and each through hole 14 extends from the upper surface 11 to the lower surface 12 . The through hole 14 is used for accommodating the electrode 20 . B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com