Method for reducing oxygen to kill pests of stored goods

A material and warehousing technology, applied in the warehousing field, can solve the problem of high energy consumption and achieve the effect of saving energy, reducing oxygen and killing insects quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the storage material is tobacco leaves, and the relative humidity of the air is 60%.

[0031] 100m 3 The stack is sealed with a composite plastic film consisting of:

[0032] 1) Determine the stacking position, place the base film of the airtight tent on the stacking position;

[0033] 2) Pile cigarette stacks on the plastic bottom film, and put storage material curing agent on the top of the cigarette stacks.

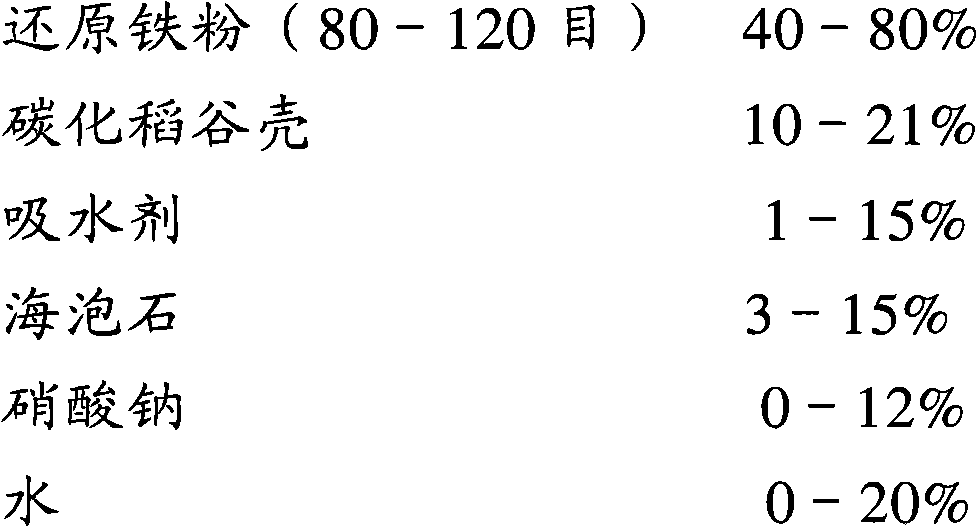

[0034] The storage material curing agent includes the following components by weight percentage:

[0035]

[0036]

[0037] Among them, calcium chloride is used as the water absorbing agent. First weigh 50kg of reduced iron powder, carbonized rice husk, calcium chloride, sepiolite, and sodium nitrate according to the weight ratio, pour them into the mixer respectively, and stir for 15 minutes. A good storage material curing agent is packed in a small package PE plastic film bag with a size of 150×210mm (the net weight of the storage...

Embodiment 2

[0044]In this embodiment, the storage material is tobacco leaves, and the relative humidity of the air is 60%.

[0045] 100m 3 The stack is sealed with a composite plastic film consisting of:

[0046] 1) Determine the stacking position, place the base film of the airtight tent on the stacking position;

[0047] 2) Pile cigarette stacks on the plastic bottom film, and put storage material curing agent on the top of the cigarette stacks.

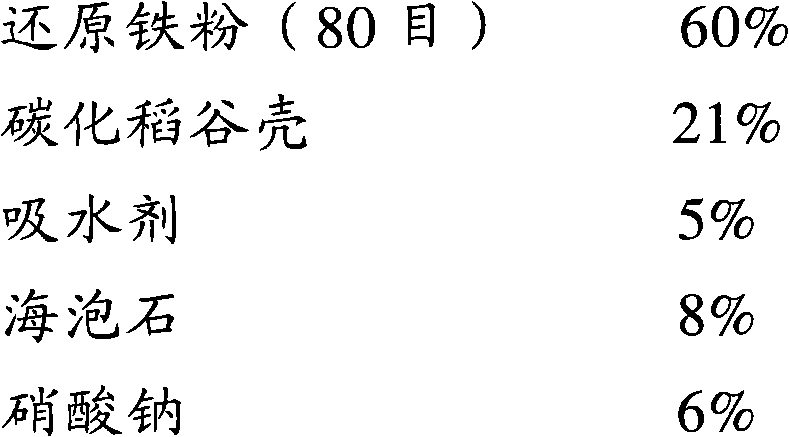

[0048] The storage material curing agent includes the following components by weight percentage:

[0049]

[0050] Among them, calcium sulfate is used as the water absorbing agent. First weigh 50kg of reduced iron powder, carbonized rice husk, calcium sulfate, sepiolite, and sodium nitrate in total, pour them into a mixer, then add water, and stir for 15 minutes. After stirring evenly, it will be made into a storage material curing agent. The prepared storage material curing agent is packed in a small package PE plastic film bag with a ...

Embodiment 3

[0057] In this embodiment, the storage material is tobacco leaves, and the relative humidity of the air is 60%.

[0058] 100m 3 The stack is sealed with a composite plastic film consisting of:

[0059] 1) Determine the stacking position, place the base film of the airtight tent on the stacking position;

[0060] 2) Pile cigarette stacks on the plastic bottom film, and put storage material curing agent on the top of the cigarette stacks.

[0061] The storage material curing agent includes the following components by weight percentage:

[0062]

[0063] Wherein, the water absorbing agent adopts anhydrous sodium sulfate. First weigh 50kg of reduced iron powder, carbonized rice husk, anhydrous sodium sulfate, sepiolite and sodium nitrate according to the weight ratio, pour them into the mixer respectively, then add water, stir for 15 minutes, and make the storage material after stirring evenly Curing agent, the prepared storage material curing agent is packed in a small pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com