Hg-Ni catalyst used in synthesis of chloroethylene by using hydrochlorination of acetylene and preparation method for Hg-Ni catalyst

A technology for the production of vinyl chloride and catalysts by chlorination, which is applied in the direction of hydrogen halide addition preparation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problem of immature development of mercury-free catalysts, no industrialization reports, and catalyst mercury content Advanced problems, to achieve the effect of easy operation, high strength and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

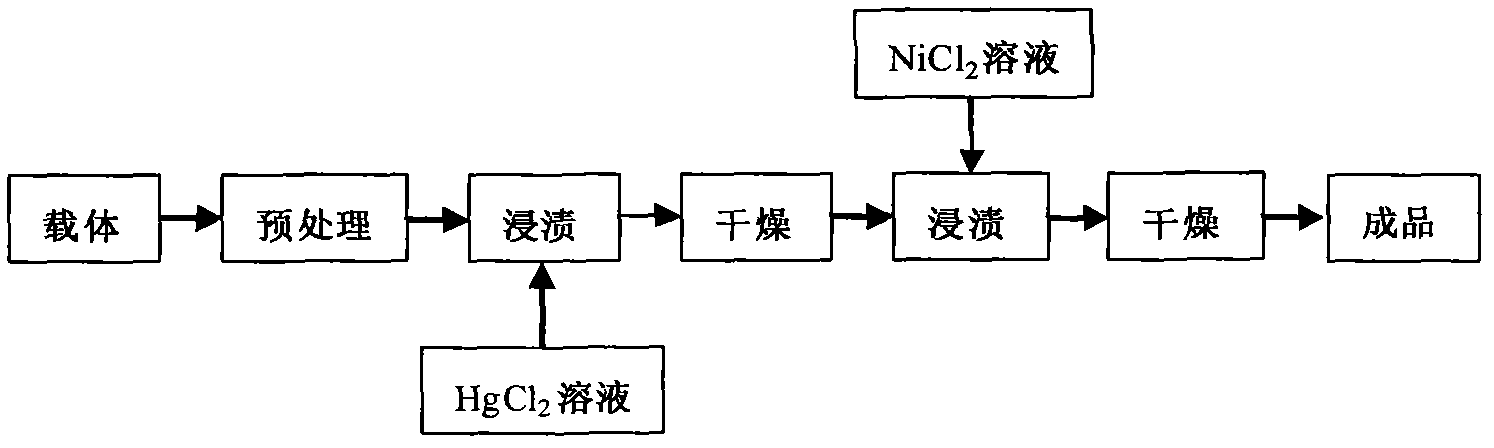

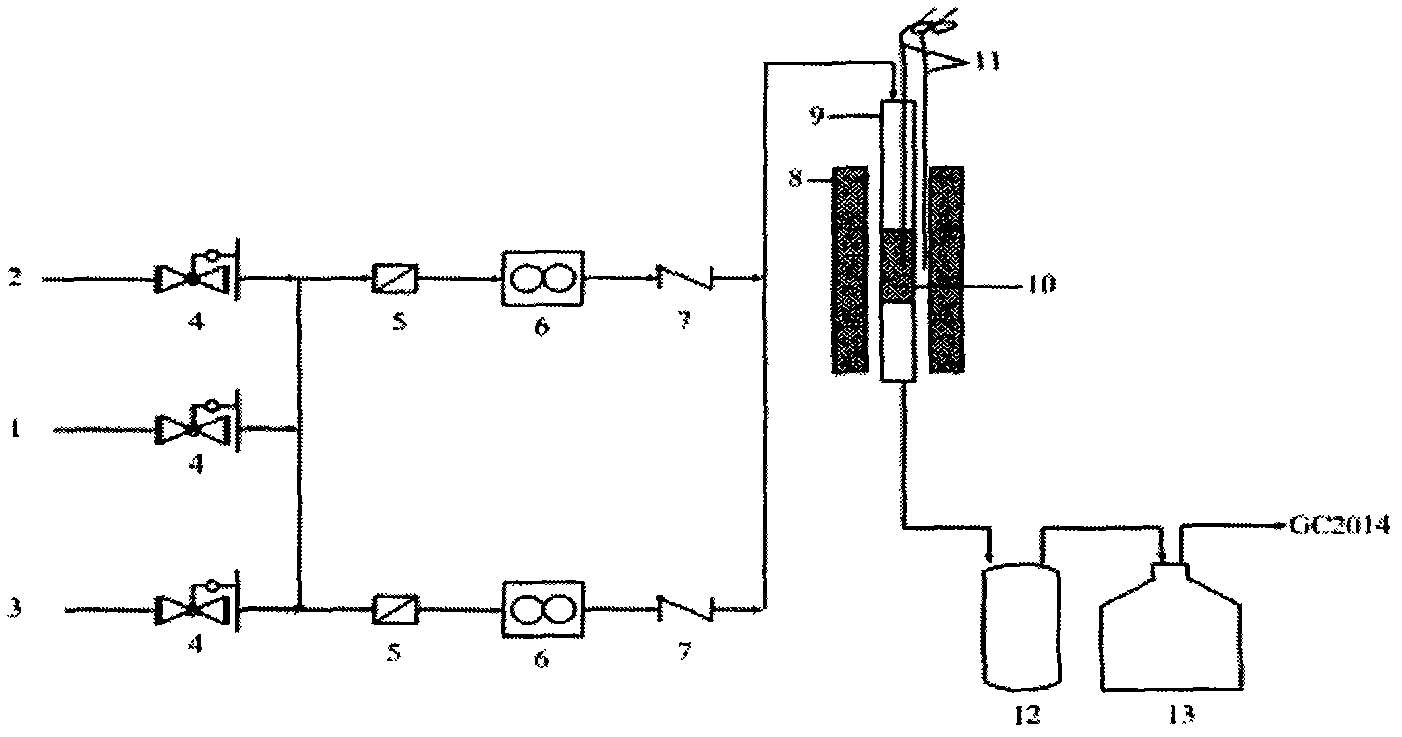

[0016] Example 1: The catalyst for the production of vinyl chloride by hydrochlorination of acetylene in this embodiment includes an inert carrier and two metal salts, wherein HgCl 2 The content of the catalyst accounts for 3% to 5% of the weight of the catalyst, and the molar ratio of Ni to Hg is 1 to 5; the active component is loaded on a porous carrier, and the porous carrier uses pitch-based, coal-based or fruit shell activated carbon. The preparation method of the catalyst for the production of vinyl chloride by acetylene hydrochlorination is as follows: 1. the metered HgCl 2 Prepare solution with dilute hydrochloric acid, final HgCl 2 The content is 3% to 5% of the weight of the catalyst; ②Immerse the inert carrier in the prepared solution, and immerse it in a constant temperature water bath at 80°C for more than 10 hours; ③Heat it on the water bath until the liquid is basically evaporated, and then put it in Dried in oven, obtains Hg catalyst; ④ nickel chloride is weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com