Online surface cleaning and protection liquid coating process of aluminum alloy high frequency welding pipes and for heat exchanger

A technology of high-frequency welded pipes and heat exchangers, which is applied to the device for coating liquid on the surface, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of cleaning and protective liquid coating process without data and solutions, etc. Achieve the effects of saving procedures, protecting the environment and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

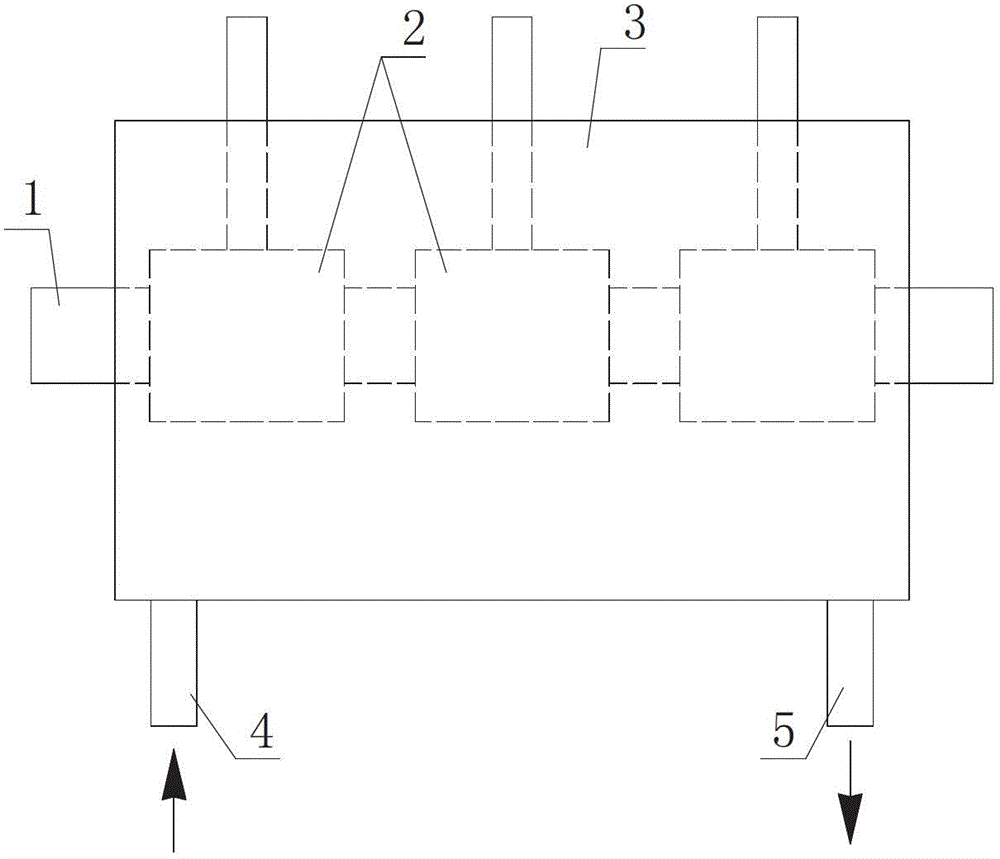

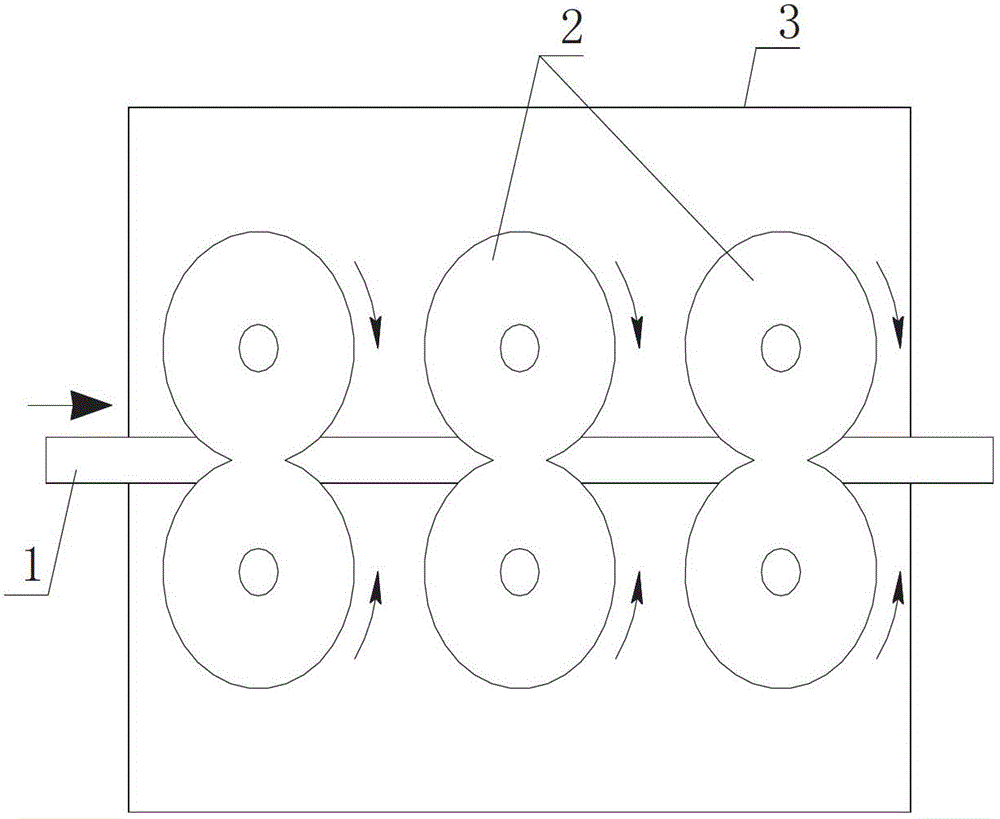

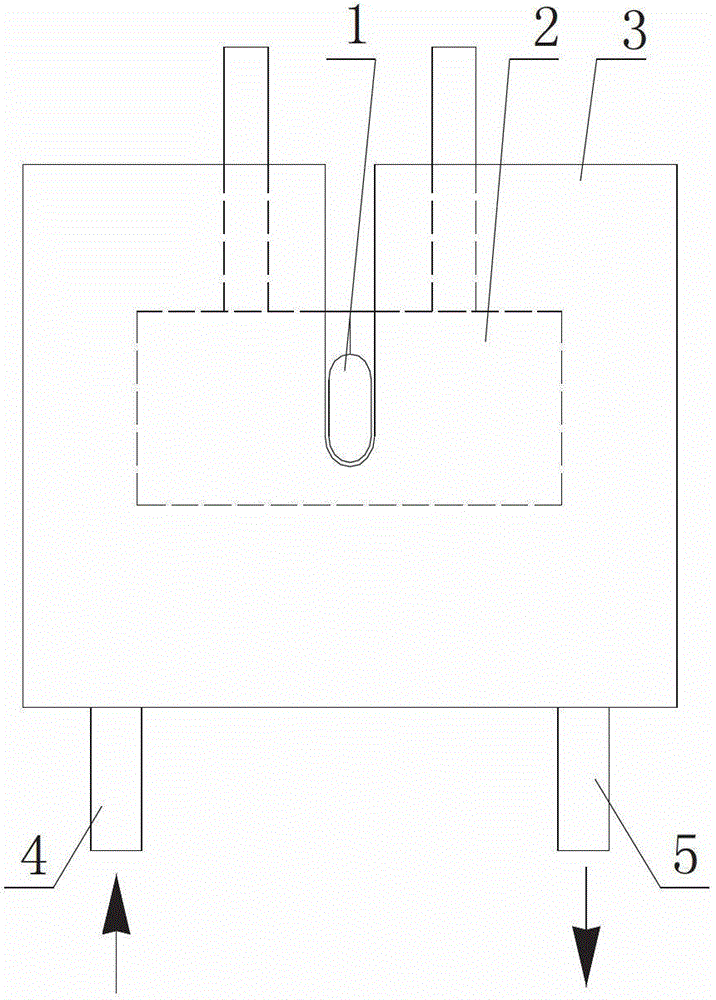

[0020] The processing technology of traditional aluminum alloy high frequency welded pipe mainly includes: strip uncoiling, shear butt welding, round pipe forming unit, guided extrusion welding, cooling device, scratching, flat pipe forming unit, flaw detection, straightening, blanking Flying shears, finished products, and aluminum alloy high-frequency welded pipe (that is, aluminum alloy flat pipe) production line are in operation, and the pipe production speed is usually between 100 m / min and 150 m / min. If the offline processing method is adopted, the workload and The cost will increase sharply, and online processing is a more feasible way. According to the heat exchanger manufacturer's requirements for the residue on the surface of the aluminum alloy high-frequency welded pipe, it does not affect the brazing, and there is no blackening on the surface visually. In view of this, the present invention carries out the product surface treatment from the process of improving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com